Introduction:

A key partner encountered recurring cracks in an LCP connector housing, even after multiple tooling adjustments. They reached out for a deeper technical analysis.

Client’s Request :Client’s Request (Anonymized Excerpt):

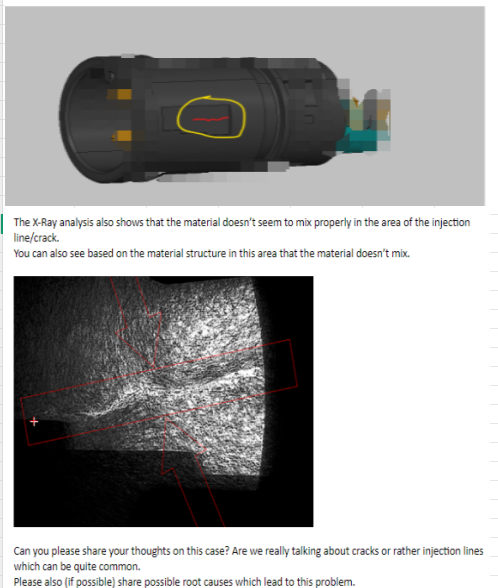

“The X-ray analysis shows that the material doesn’t mix properly near the injection line. Can you share possible root causes and solutions?”

Problem Identified:

✔ Weld line weakness due to single-gate flow in thin-walled design

✔ Incomplete material fusion, confirmed via microscopy & X-ray

✔ Suboptimal process parameters for LCP material

Our Solution:

✅ Mold Redesign – Recommended multi-gate feeding for uniform material distribution

✅ Process Optimization – Fine-tuned temperature, pressure, and cooling rates

✅ Material Guidance – Advised on LCP-specific best practices

Outcome:

- Defect rate reduced to near-zero in subsequent production runs

- Client gained confidence in long-term manufacturability

Why Partner With Us?

🔹 Technical Collaboration – We don’t just supply parts; we solve problems.

🔹 Data-Driven Approach – Leveraging microscopy, X-ray, and simulation tools.

🔹 Industry Expertise – Deep knowledge of high-performance polymers like LCP.

📞 Need help with a complex molding challenge? contact us at sales1@rilong-mold.com / sherry@rilong-mold.com today!