You’ve probably heard this before: “Moldflow Analysis saves time, cost, and prevents defects.” But how exactly does it work? Let’s break it down.

🧠 You’re the Customer, and You’re Curious…

“Every supplier tells me moldflow is important. They say it saves cost, shortens development time, avoids mold damage.

But I still wonder — how does this actually happen? Is this just technical talk to impress me? Or does it really make a difference?”

Let’s walk you through the real logic, real benefits, and real impact of moldflow analysis — in a way that makes sense whether you’re an engineer or a sourcing manager.

📌 What Is Moldflow Analysis, in Simple Terms?

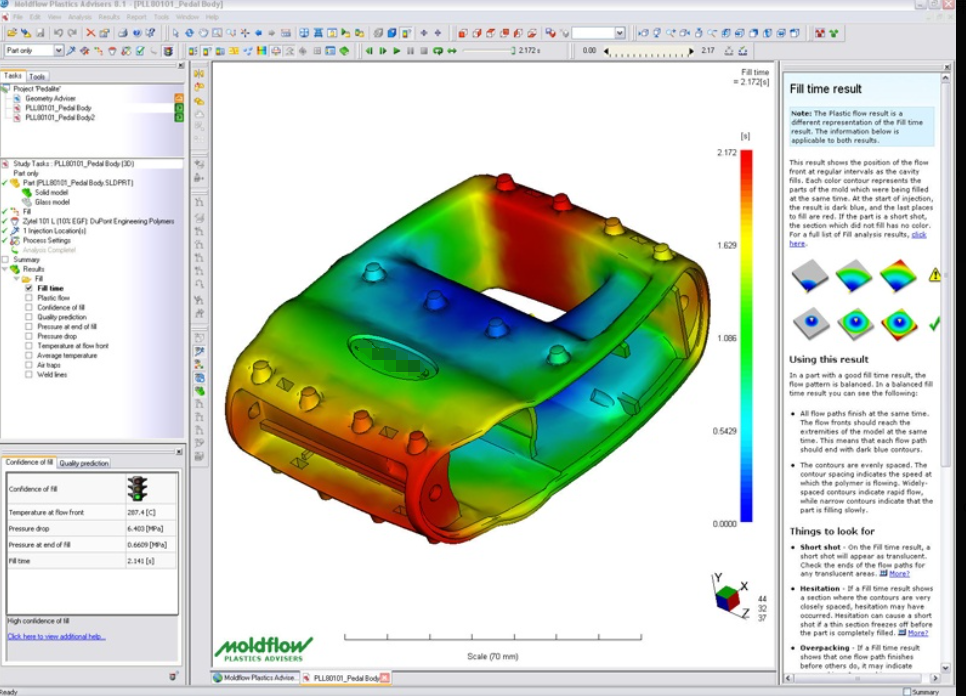

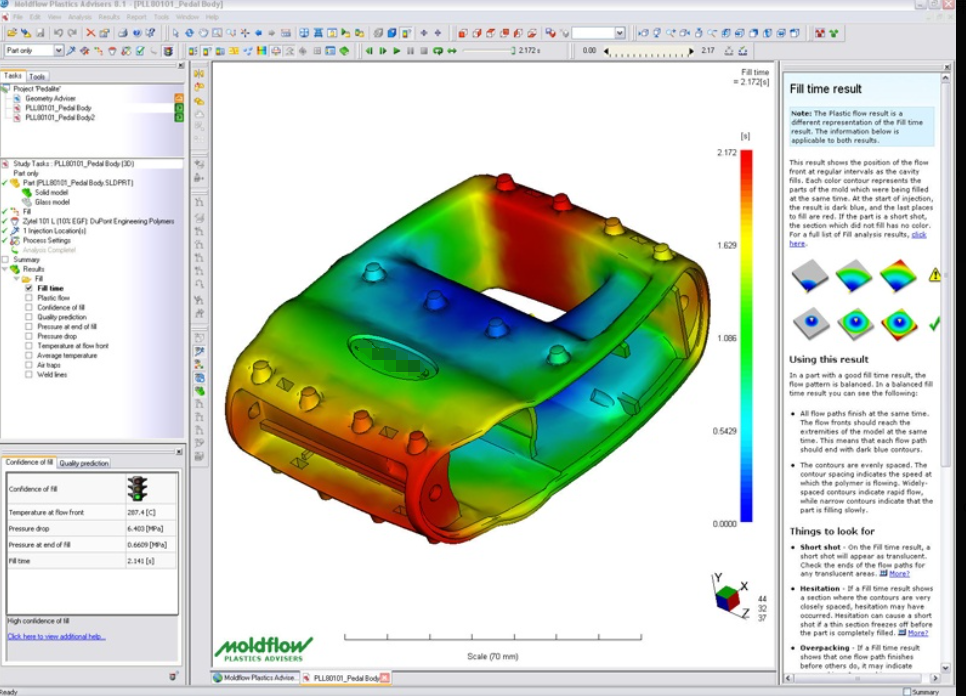

Moldflow analysis is a simulation of how molten plastic flows inside a mold cavity during injection molding.

Think of it as a virtual test shot — but done before we cut steel or make any real mold.

With this simulation, we can:

- Optimize the gate location and flow path

- Predict how the plastic fills the cavity

- Find where air traps, weld lines, or short shots may occur

- Evaluate pressure, temperature, and cooling behavior

🔍 What Problems Can Moldflow Reveal Before They Happen?

| Issue | What It Looks Like | How Moldflow Helps |

|---|---|---|

| Short Shot | Incomplete filling | Simulates flow to ensure full cavity fill |

| Weld Line | Weak joint line | Predicts position to adjust design or gate |

| Warpage | Part deformation | Simulates shrinkage and stress |

| Air Trap | Burn marks or voids | Predicts trapped air zones for better venting |

| Uneven Cooling | Sink marks or distortion | Shows temperature balance, suggests cooling channel changes |

💡 When Do We Run Moldflow?

The best time is before mold fabrication — during the DFM (Design for Manufacturability) review.

It’s even better if we can do it while finalizing your 3D part design, so we can:

- Reduce rework during mold trial

- Recommend wall thickness adjustments

- Optimize parting line or gate positioning

🚀 Real Business Benefits — Not Just Engineering Jargon

✅ Faster Time to Market

Avoid unnecessary rework or mold modification. First trial → Ready to go.

✅ Lower Project Cost

Fewer mold revisions = lower tooling cost = higher ROI.

✅ Higher Quality Parts

Better control over flow, stress, shrinkage = better product consistency.

✅ More Professional Development Process

You gain confidence that we understand your part — from concept to production.

📈 How You Can Use Moldflow to Your Advantage

When your supplier provides a moldflow report, you should expect:

- A clear visual of filling simulation

- Marked areas of risk: weld lines, air traps, sink

- Gate location justification

- Design recommendations, not just charts

This helps you as the customer:

- Trust that your supplier knows what they’re doing

- Make design decisions faster

- Communicate more clearly across your team

🤝 Our Commitment: Moldflow for Every Project

We include moldflow simulation in every tooling project — not just to impress you with tech, but because we know:

Every defect we prevent at the design stage saves weeks and thousands of dollars down the line.

Ready to Build Smarter, Not Just Faster?

Let’s start with a conversation — show Rilong your design, and we’ll show you how to improve it before steel is cut.