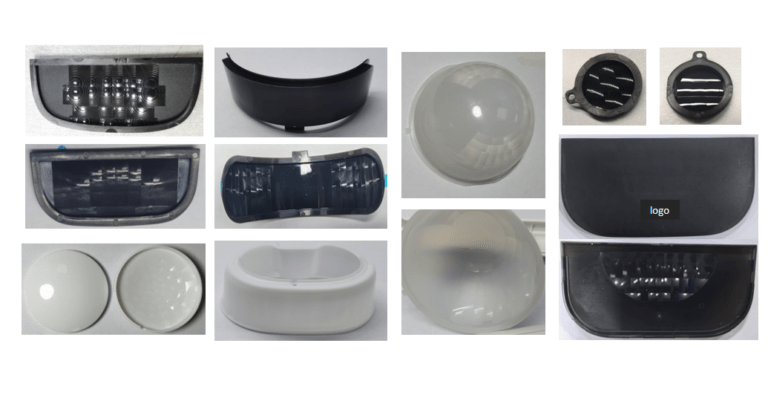

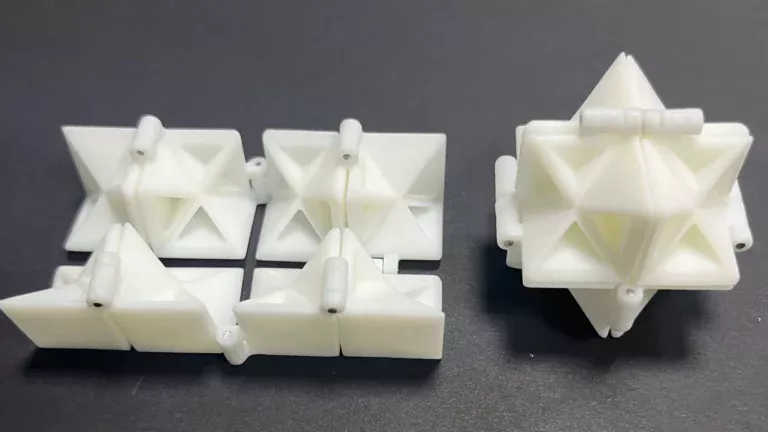

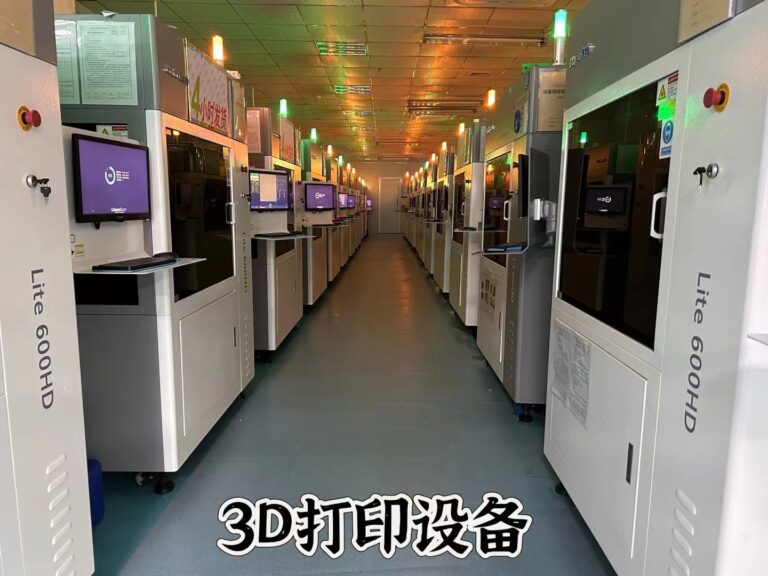

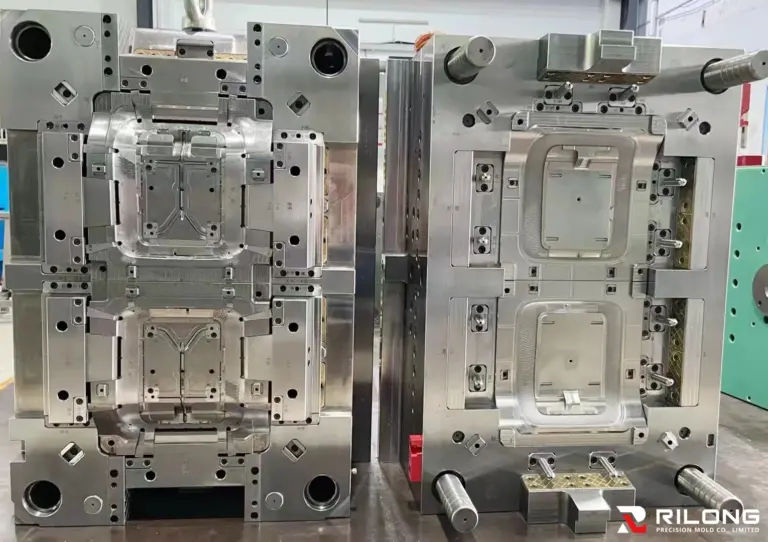

Plastic Material PMMA and its Properties

PMMA is one of the commonly plastic transparent materials, let us know more about it 1. Performance of PMMA PMMA is an amorphous polymer, commonly known as organic glass. It has excellent transparency, good heat resistance (heat deformation temperature is…