Achieving crisp backlit symbols on light-transmitting buttons requires precision laser technology. Standard laser etching often carbonizes the substrate, reducing light transmission by over 50%. Discover how our specialized process delivers flawless results while preserving 90%+ light throughput.

1. The Industry Challenge: Why Most Laser Marking Fails

❌ Conventional YAG lasers:

- Simultaneously remove paint and scorch transparent plastic

- Create light-blocking carbon layers

- Result in:

✓ Uneven backlighting (30-40% transmission)

✓ Blurred symbols

✓ Reduced button lifespan

Case Study:

Automotive audio buttons lost 55% light output after standard laser processing.

2. Our Proprietary Solution

⚙️ Specialized Equipment:

- Beam-shaping optics for 0.01mm depth control

- Dynamic power adjustment (15W-30W)

- 50kHz pulse frequency to prevent heat buildup

📊 Performance Comparison:

| Parameter | Standard | Our Method |

|---|---|---|

| Light Transmission | ≤40% | ≥90% |

| Edge Definition | ±0.1mm | ±0.02mm |

| Heat Affected Zone | Visible | None |

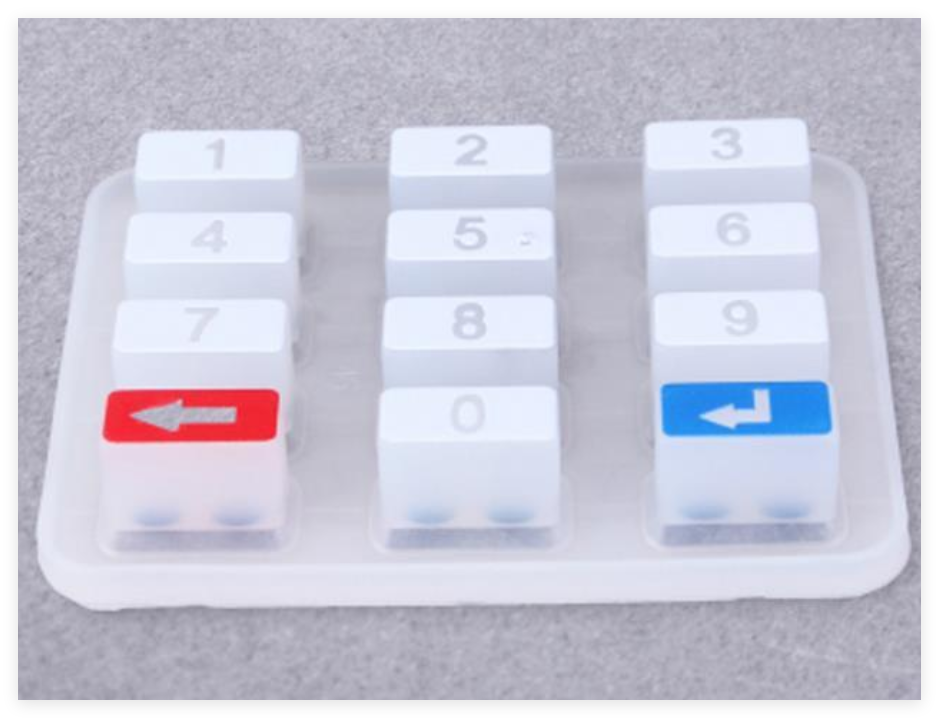

3. Light-Through Button Anatomy

Optical Pathway Design:

- Light Guide Structure:

- LED coupling interface (side-mounted)

- 45° primary reflector

- Dual-function secondary reflector (touch surface + light redirection)

- Laser Process Criticals:

- Removes 5μm paint layer only

- Maintains pristine light channels

4. Applications & Success Stories

🔘 Consumer Electronics: Phone keypads

🚗 Automotive: Dashboard controls

🏭 Industrial: Instrument panels

🏠 Smart Home: Illuminated switches

Client Result:

Global automotive supplier achieved 99.3% yield (from 72%)

Welcome to exchange more ideas with us at www.rilong-mold.com.