In the world of precision mold manufacturing, the margin for error is zero. At [RiLong Precision Mold], we believe that true precision is a promise that must be validated, not just claimed. While our engineering and craftsmanship set the stage, it is our rigorous quality assurance process that delivers the final, undeniable proof of excellence. Central to this process is our advanced Coordinate Measuring Machine (CMM) technology, the gold standard in metrology for verifying dimensional accuracy.

Image Box Title

Change this description

The Non-Negotiable Standard: Dimensional Precision

Every mold component we manufacture is designed to perform a specific function under demanding conditions. Even a microscopic deviation from specified tolerances can lead to part failure, production delays, and costly downtime for our clients. This is why we adhere to a simple but uncompromising philosophy: every critical dimension must be verified with objective, data-driven evidence.

Image Box Title

Change this description

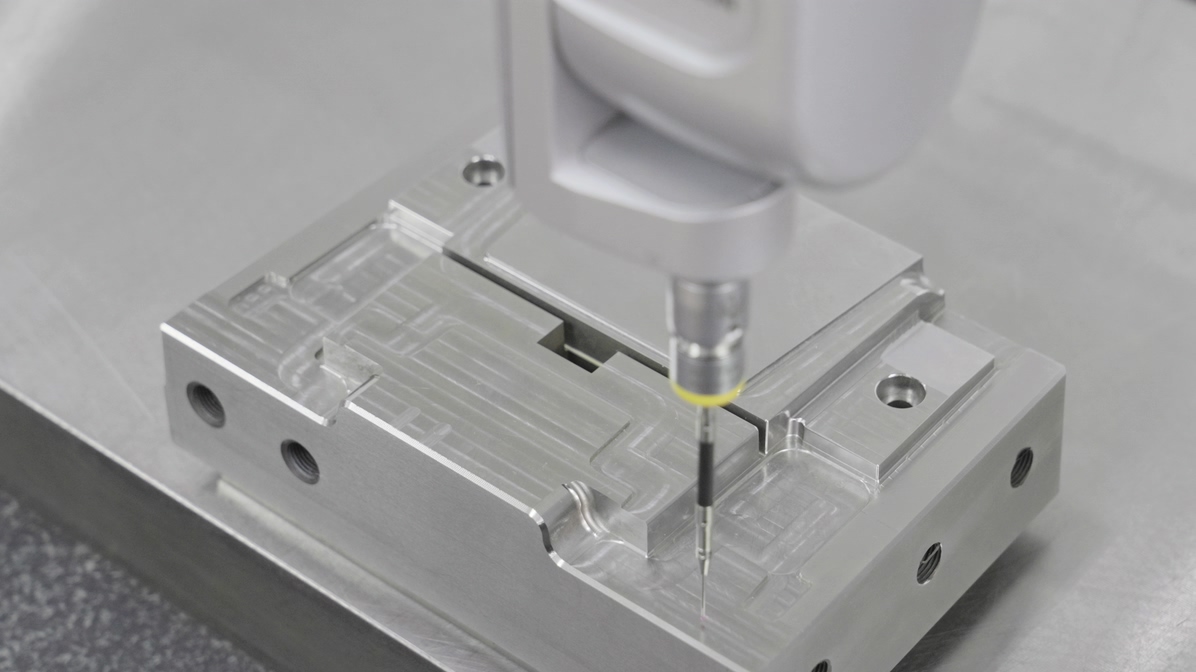

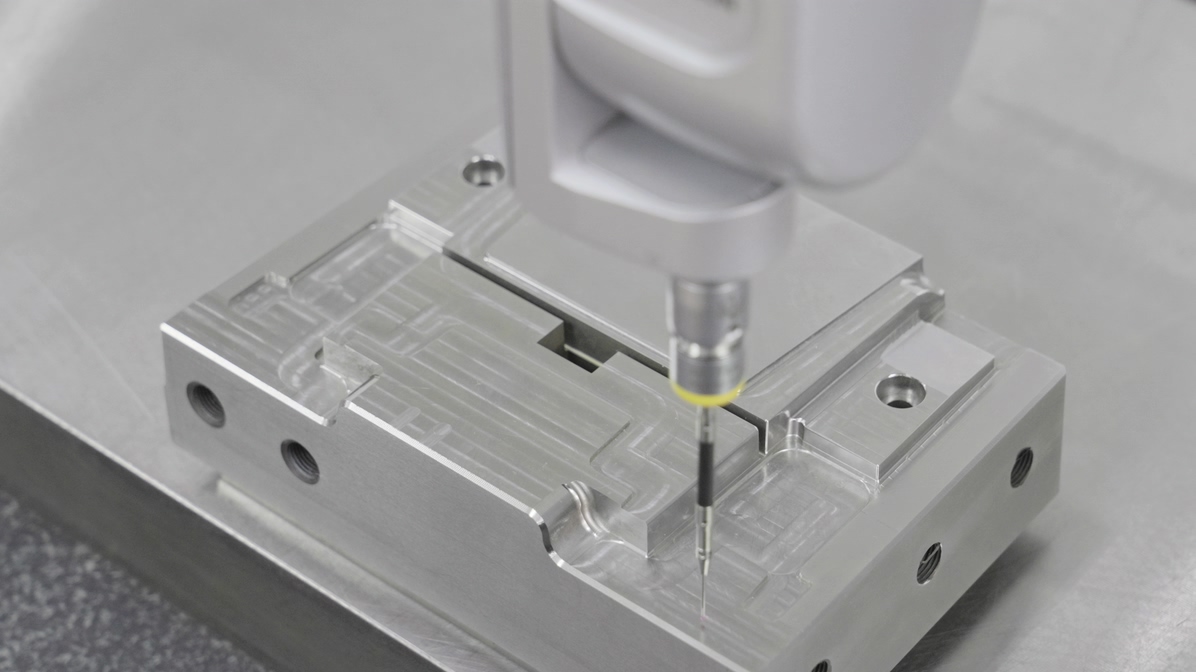

Our Technology: Advanced 3D CMM Inspection

To uphold this standard, we employ state-of-the-art CMM equipment. This sophisticated 3D scanning system creates a high-resolution digital map of a component’s geometry, measuring its exact dimensions with micron-level accuracy.

The process is simple yet powerful:

- A core mold (workpiece) is placed on the CMM machine.

- A probe meticulously captures millions of data points from the component’s surface.

- These measurements are instantly compared against the original digital CAD design.

- A comprehensive report is generated, confirming compliance with all specified tolerances.

Image Box Title

Change this description

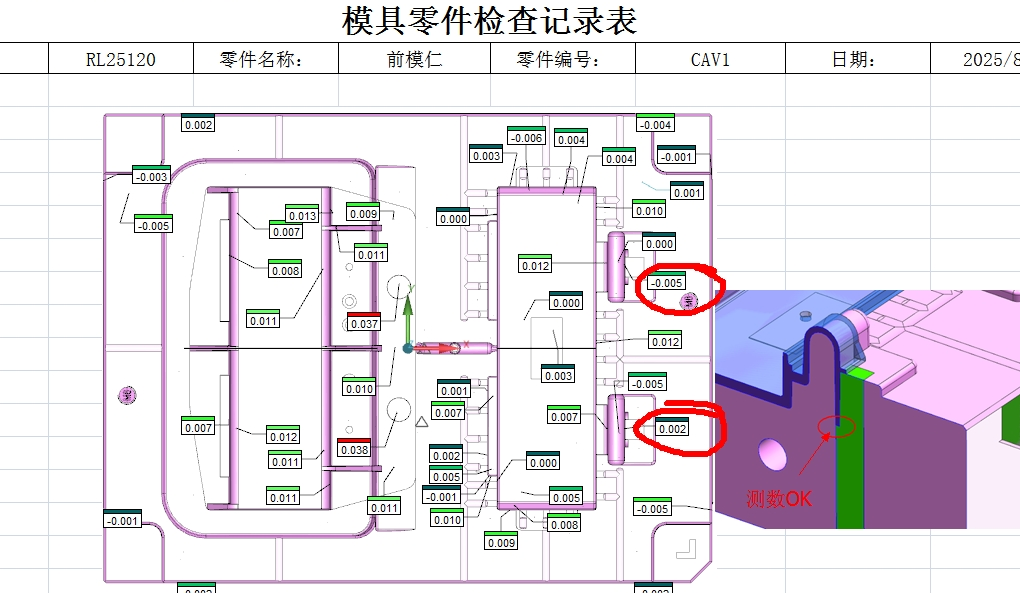

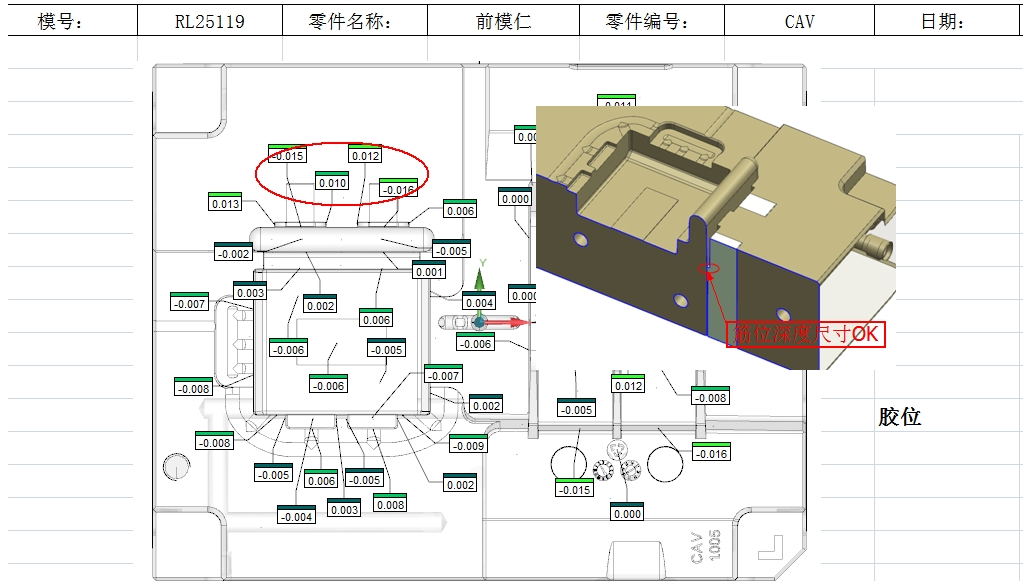

The Proof is in the Report: Transparency and Trust

We don’t just tell you our molds are precise; we show you. The detailed inspection report (like the one shown above) provides a clear, unbiased record of quality. It offers:

- Data-Driven Validation: Concrete proof that every feature—every bore, cavity, and thread—is within tolerance.

- Full Traceability: A permanent record for quality control and future production runs.

- Complete Peace of Mind: The assurance that the tooling you receive is guaranteed to perform as intended from its first production cycle.

Image Box Title

Change this description

Ready to experience the difference that verified precision makes?

Please get in touch with us to discuss your next project and learn how our commitment to quality can bring you unparalleled reliability and performance.