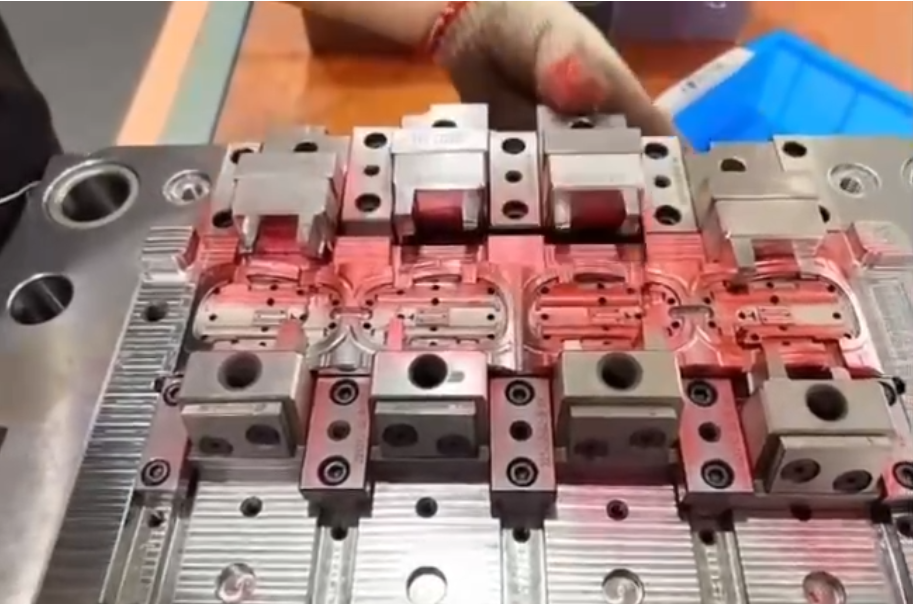

In mold manufacturing, achieving perfect alignment is critical—and one of the oldest tricks in the book involves a striking red coating on mold surfaces. If you’ve ever wondered why assembly technicians use this method, here’s a deep dive into its purpose, benefits, and enduring relevance in modern manufacturing.

What Is the Red Coating on Mold Surfaces?

The vibrant red layer, traditionally known as Prussian Blue or Red Lead Paste (now replaced by eco-friendly, non-toxic alternatives), is a high-precision gap detection tool. It’s applied during mold assembly to identify microscopic misalignments that could compromise product quality.

How Does It Work?

- Anwendung: Technicians spread the paste on one mold surface.

- Press Test: The mating surface is pressed against it and then separated.

- Inspection:

- Uniform red transfer → Perfect alignment (✅).

- Patchy or missing areas → Gaps exist (⚠️), requiring adjustments.

This method reveals inconsistencies as small as microns, far beyond what the naked eye or even some machines can detect.

4 Key Benefits of the Red Paste Method

- Prevents Defects

- Eliminates burrs, flash, and dimensional inaccuracies in final products.

- Saves Time & Cost

- Reduces rework by catching alignment issues early in assembly.

- Extends Mold Lifespan

- Ensures even force distribution, reducing wear and tear.

- Versatility

- Works on complex geometries where laser/sensor-based systems may struggle.

Will Automation Replace This “Old-School” Technique?

While advanced technologies like 3D scanning and laser alignment are gaining traction, the red paste method remains widely used because:

- Low cost: No expensive equipment required.

- High reliability: Effective for intricate molds.

- Quick cleanup: Removes easily with solvents, leaving no residue.

Industry Insights: When Is It Still Indispensable?

- Prototyping: Rapid verification of new mold designs.

- Large/Complex Molds: Where sensor coverage may be impractical.

- Maintenance Checks: Diagnosing wear-related misalignments.

Fazit

The red coating isn’t just a cosmetic quirk—it’s a time-tested precision tool that balances simplicity and accuracy. As manufacturing evolves, this method continues to complement high-tech solutions, proving that sometimes, the simplest ideas are the most enduring.

Need expert mold manufacturing with zero alignment defects? Contact Rilong at sales1@rilong-mold.com for solutions combining traditional craftsmanship and cutting-edge technology.