With over 30 years of manufacturing experience, Rilong specializes in mold design, development, and production for plastic and rubber molds and products. Our expertise covers hard and soft plastic over-molding parts, soft plastic and metal over-molding parts, double injection, LSR/LSR over-molding, and membrane keypads. We also provide comprehensive finishing and assembly services, including screen/pad printing, spraying, laser etching, hot melting, insert molding, packing, and final assembly.

Rilong is certified to ISO9001, ISO14001, IATF16949, and ISO13485, and all materials comply with RoHS, REACH, and UL standards. We have long-term partnerships with many world-renowned companies such as Honeywell, Siemens, Topcon, Tyco, Canon, Axis, Finisar, Toshiba, and many others. Rilong has been recognized as one of the most reliable partners of these well-known companies in China.

1.Mold Design & Manufacturing

8 Advanced CNC machines: Charmilles, Seiki, MITSUBISHI

7 Advanced EDM : CHARMILLES, SODICK

2 Advanced WEDM: CHARMILLES, SODICK

Grinding, Milling, Manual grinding. CMM Tester, 2D tester…

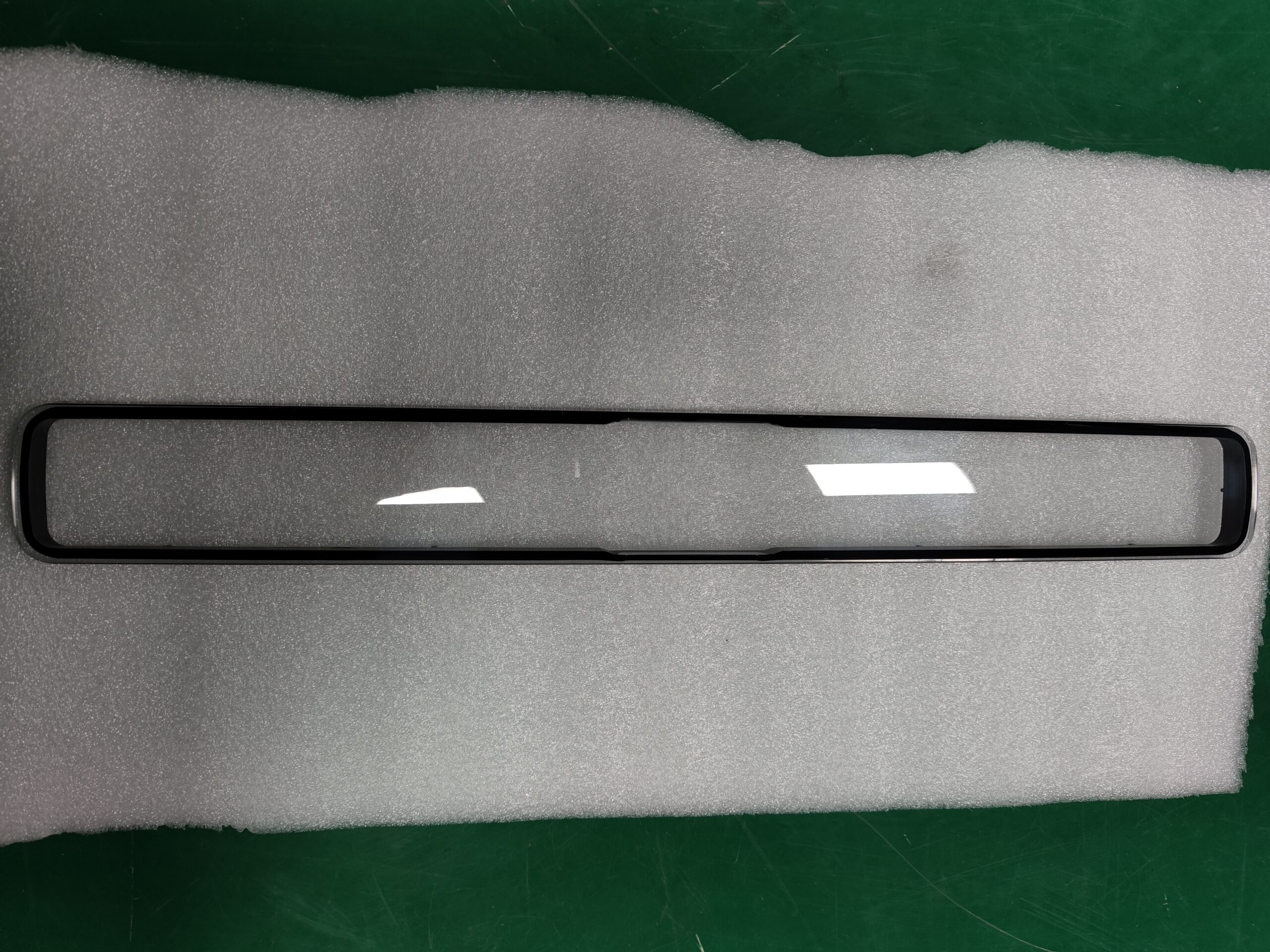

2. Injection Molding

Rilong provides high-precision injection molding for a wide range of plastic components, delivering consistent quality even for complex geometries and tight tolerances. Our advanced equipment and process control ensure stable production for both low- and high-volume projects.

3. Double Injection Molding

Our double injection molding capability allows different materials or colors to be molded in one integrated process. This technique enhances product functionality, improves bonding strength, and offers greater design flexibility.

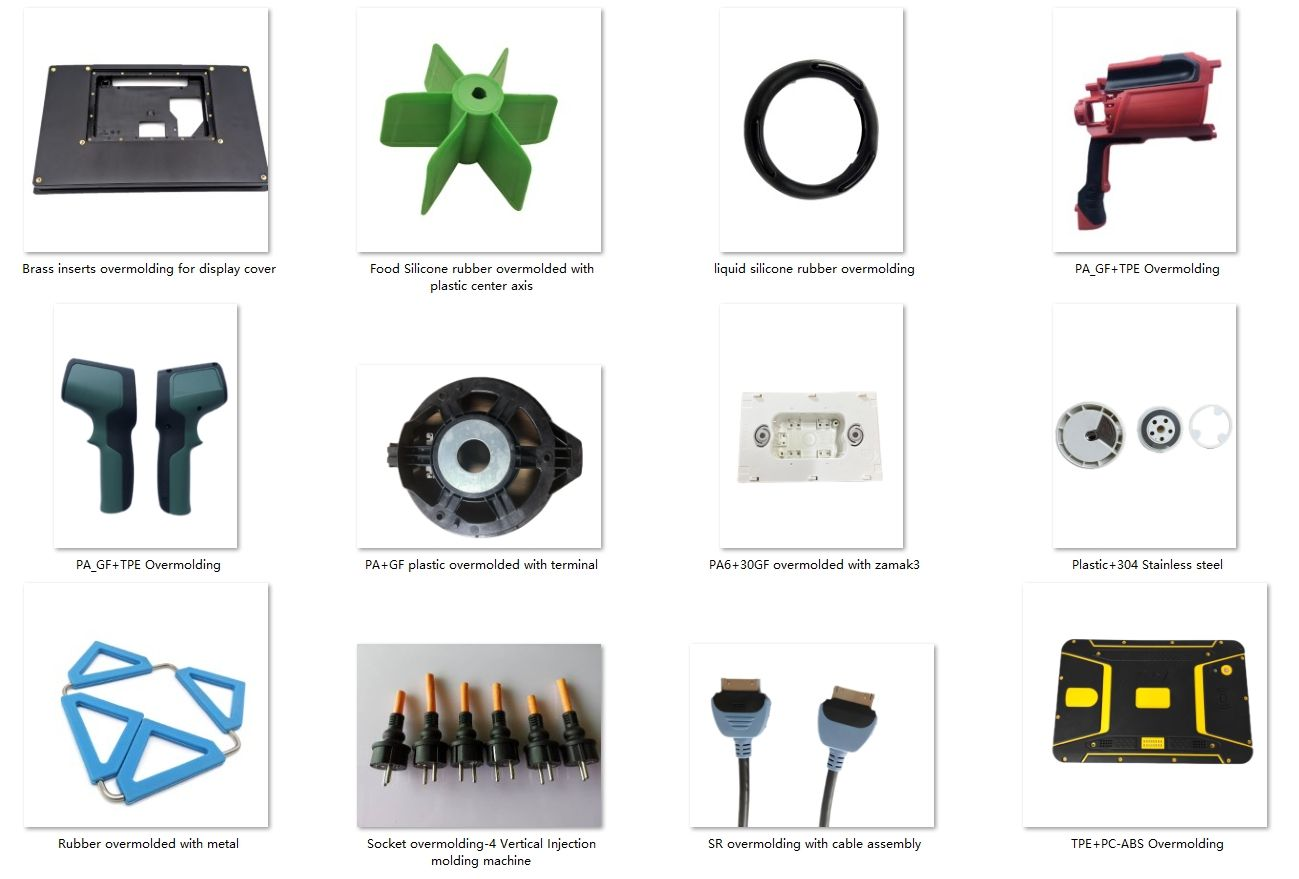

4. Over-Molding

Rilong specializes in over-molding soft plastics onto hard plastics or metal components. This process creates durable, ergonomic, and reliable products widely used in consumer electronics, industrial controls, medical devices, and automotive applications.

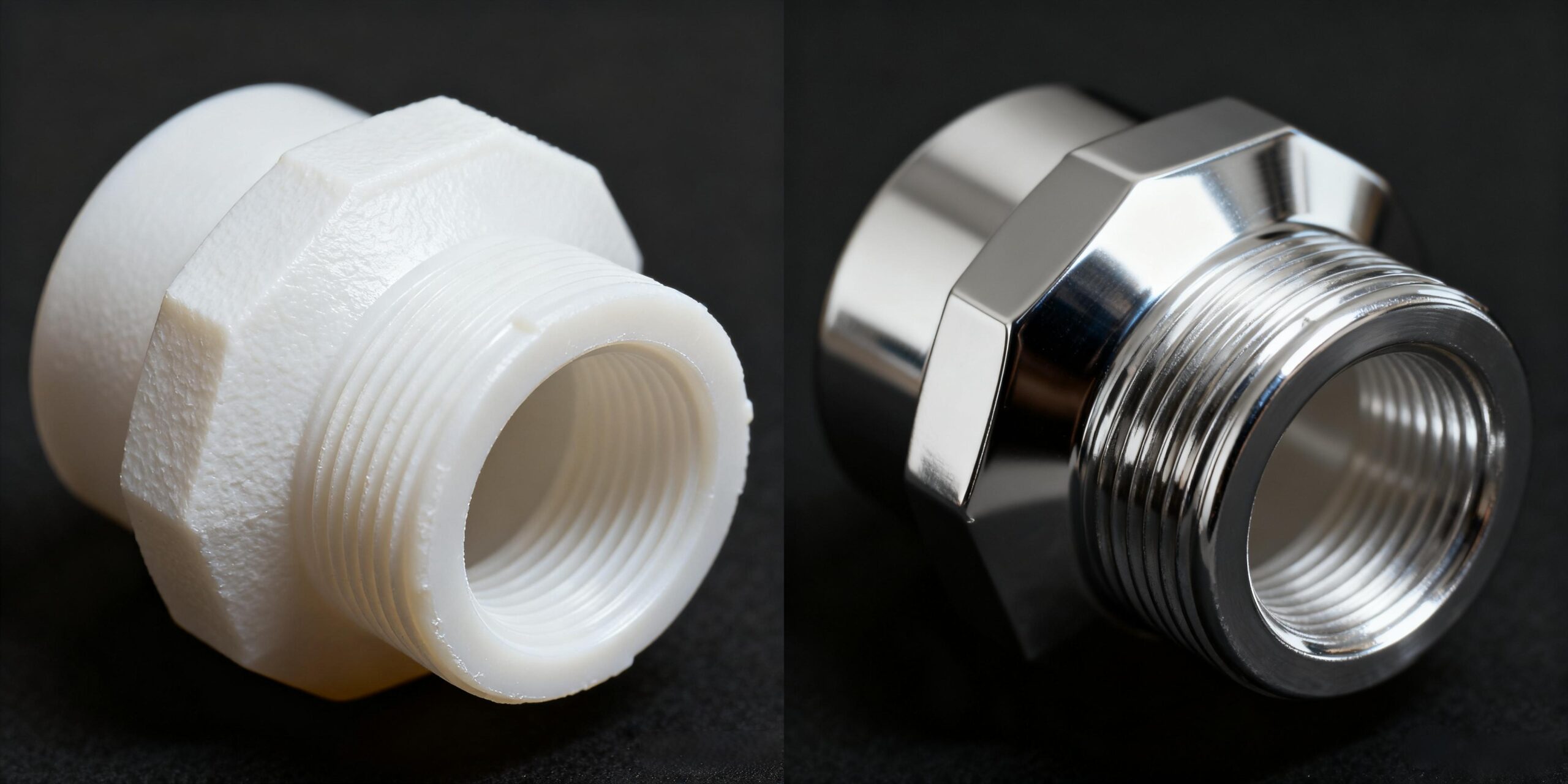

5. Rubber Molding

Rilong produces high-quality rubber components with excellent resilience, anti-aging properties, and chemical resistance. We support EPDM, NBR, silicone rubber, and many other material options based on customers’ application needs.

6. LSR Over-Molding

We offer LSR-to-plastic and LSR-to-LSR over-molding solutions. With precise temperature and material control, Rilong ensures excellent sealing performance, biocompatibility, and long-term durability—ideal for medical and high-end industrial applications.

7. Secondary Finishing & Assembly

We provide comprehensive one-stop finishing services, including screen/pad printing, laser etching, spraying, hot melting, insert molding, ultrasonic welding, packing, and final assembly. This ensures seamless quality control from raw materials to finished products.

At Rilong, our commitment to precision, innovation, and reliability drives everything we do—from world-class mold manufacturing to high-quality molding production and value-added finishing services. With decades of experience and long-term cooperation with global industry leaders, we continue to deliver solutions that meet the highest standards of performance and consistency.

We welcome you to explore how Rilong can support your next project with professional engineering, dependable production, and exceptional service.