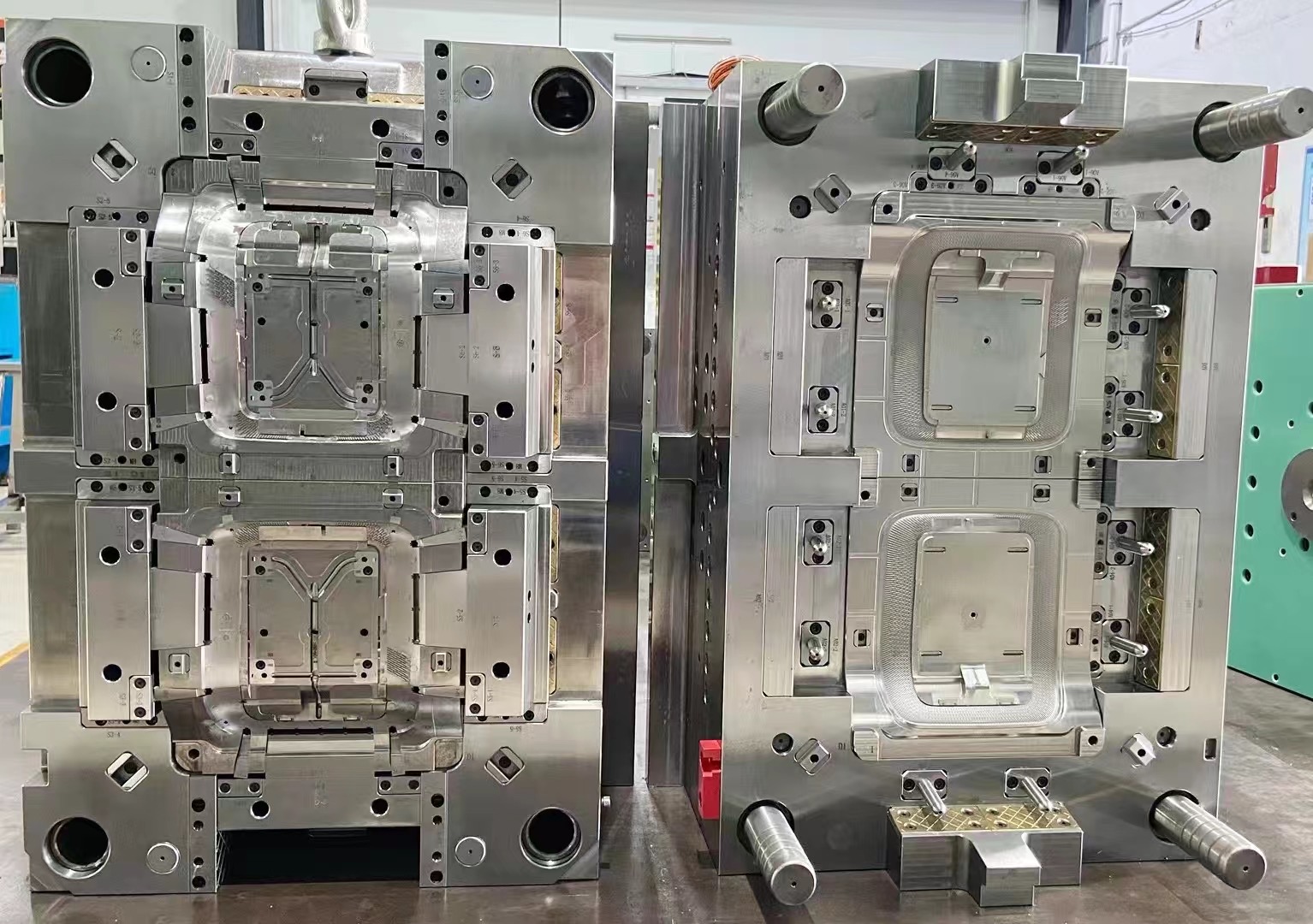

Building Confidence in Transfer-Ready Mold Manufacturing

Yes, we can manufacture molds suitable for Global Production — and more importantly, we design and build them with transfer-readiness and long-term production stability in mind.

For customers who plan to transfer molds to local production facilities, tooling quality, documentation, and compatibility with international standards are critical. This is where our strengths lie.

Advanced Tooling Equipment for High-Precision Molds

Our manufacturing facility is equipped with high-precision machinery from leading global brands, including:

- Sodick

- Charmilles

- FANUC

- And other advanced CNC, EDM, and grinding equipment

These machines enable us to achieve exceptional dimensional accuracy, surface consistency, and repeatability, which are essential for molds that must perform reliably after transfer to a different production environment.

20+ Years of Engineering Experience in Export Molds

Our engineering team brings over 20 years of hands-on experience in mold design and manufacturing, with a strong focus on export and transfer-ready tooling projects.

This experience allows us to:

- Fully understand international mold standards and expectations

- Design molds that are compatible with overseas injection molding machines

- Anticipate common issues during mold transfer and prevent them at the design stage

As a result, our molds are built not only to pass initial trials, but also to support stable, long-term production after relocation.

Certified Quality Systems & Process Control

Quality assurance is embedded into every step of our tooling process.

We are certified with:

- ISO 9001 – Quality Management System

- ISO 14001 – Environmental Management System

- IATF 16949 – Automotive Quality Management

In addition, we strictly implement the 7S management system to ensure high operational efficiency, traceability, and process control throughout mold manufacturing.

These systems form the backbone of our commitment to consistent quality, environmental responsibility, and on-time delivery.

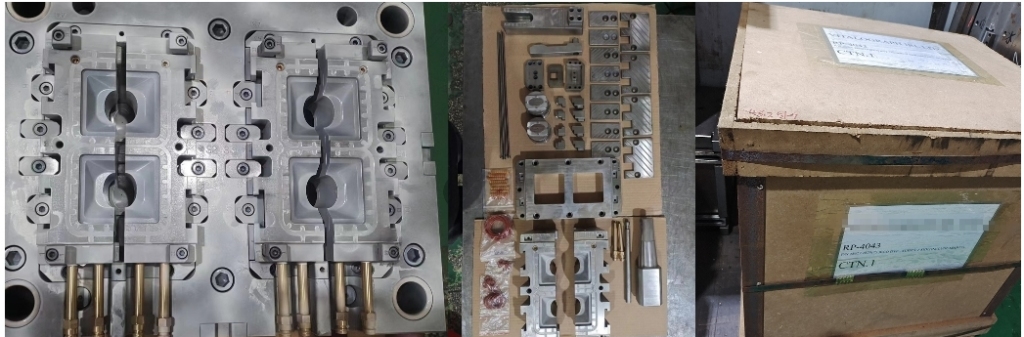

In-Process Inspection & Measurement at Every Critical Stage

Built-In Quality Control, Not Just Final Inspection

With CMM, VMS, Color Tester, and other inspection equipment in-house, we conduct inspections at every key stage — from electrodes and mold components to final mold assembly. This ensures consistent quality and reliable performance, especially for transfer-ready molds.

Steel Selection Optimized for Mold Transfer & Mold Life

For molds that will be transferred to a customer’s local production site, we typically recommend proven steel grades such as:

- 718H

- S136

- 2083

- S7M or equivalent high-grade steels

Based on your expected mold life, production volume, and application, we will recommend the most suitable steel option to ensure durability, ease of maintenance, and stable performance after transfer.

Information Required for a Proper Mold Evaluation

To conduct a thorough and accurate mold evaluation, we kindly request the following information:

- 2D and 3D product drawings

- Specific mold requirements, such as:

- Hot runner or cold runner preference

- Expected mold lifespan

- Number of cavities

- Any special technical or cosmetic requirements

- Injection molding machine specifications

- If available, please provide the full machine specification sheet

- If not, kindly inform us of the machine tonnage

This information allows us to evaluate compatibility, optimize the mold design, and ensure a smooth mold transfer and ramp-up process.

Your Trusted Partner for Transfer-Ready Tooling

With advanced equipment, experienced engineers, certified quality systems, and a deep understanding of international production requirements, we are confident in our ability to deliver high-quality, transfer-ready molds that support stable, long-term production performance.

If you are planning to manufacture molds locally or transfer tooling across regions, we are ready to support your project from design to successful production.