Liquid Silicone Rubber Custom Component Solutions

What is LSR Molding?

Liquid Silicone Rubber (LSR) injection molding is a process where liquid A & B components are precisely mixed, injected into a mold, and thermally cured to create high-performance silicone parts. Unlike traditional rubber, LSR offers:

✔ Ultra-low shrinkage (∼0.1%)

✔ Exceptional durability (heat, chemical & UV resistant)

✔ Medical & food-grade safety (FDA, LFGB compliant)

LSR Double Injection: The Next-Level Advantage

Combine LSR with thermoplastics or other materials via two-shot molding for:

✔ Seamless bonding – No adhesives needed, just ultra-strong, leak-proof assemblies

✔ Multi-material flexibility – Soft-touch grips + rigid structures in a single cycle

✔ Cost-efficient production – Reduced assembly steps, higher consistency

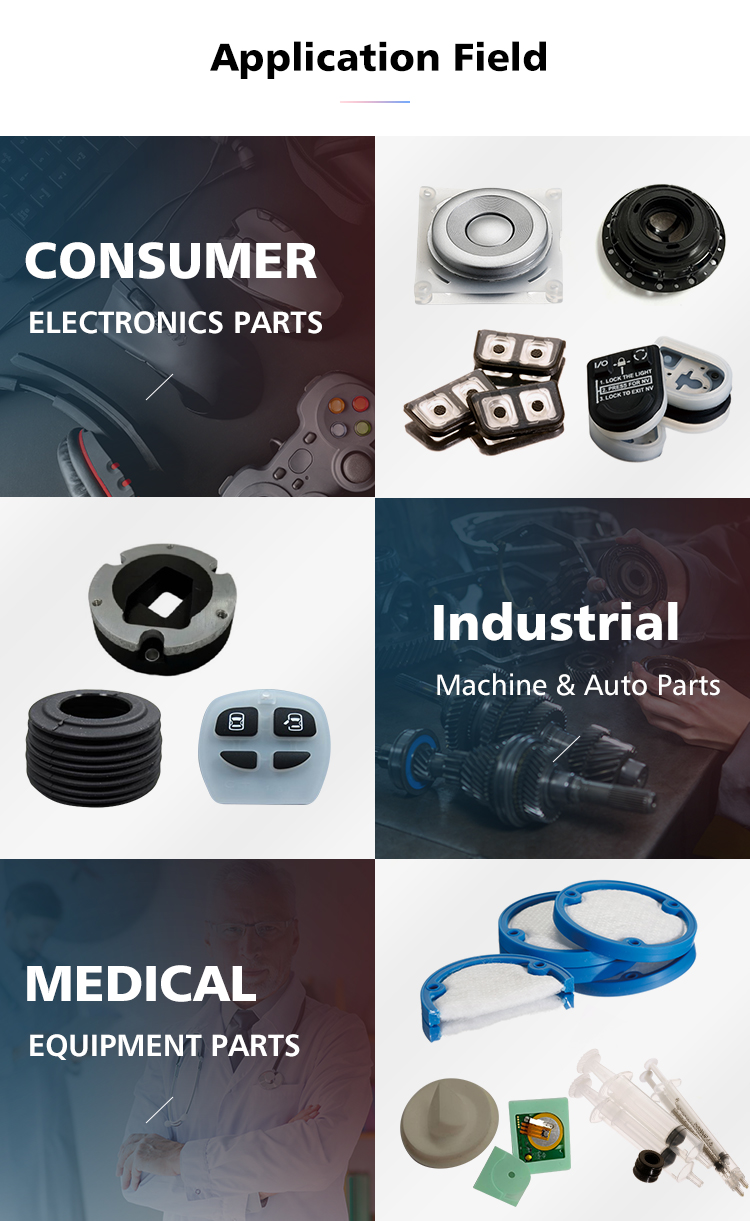

Expanding LSR Applications Across Industries

🏥 Medical & Healthcare

• Surgical Tools: Blood-contact devices with autoclave resistance

• Wearable Health Tech: Skin-adhesive ECG electrodes

• Pharma Delivery: Self-sealing vial stoppers

🚗 Automotive & EV

• Battery Thermal Pads: Flame-retardant insulation

• Sensor Seals: Autonomous vehicle LiDAR protection

• Overmolded Connectors: IP68-rated charging ports

🔌 Electronics & 5G

• 5G Base Station Gaskets: Weatherproof RF enclosures

• Tactile Keypads: Million-cycle lifespan

• Underfill Encapsulation: Chip shock absorption

🏭 Industrial & Energy

• Solar Panel Edge Seals: UV-resistant bonding

• Hydraulic Seals: -40°C cold-flex performance

• Robotic Grippers: Food-grade compliant

🛒 Consumer Goods

• Smartwatch Bands: Hypoallergenic comfort

• Air Fryer Gaskets: 250°C oil resistance

• VR Face Interfaces: Sweat-proof cushioning

LSR Molding Technology

🔹 Standard LSR Injection – Seals, gaskets, soft-touch components

🔹 Special LSR Formulations – High-temp, electrically conductive, or optically clear silicones

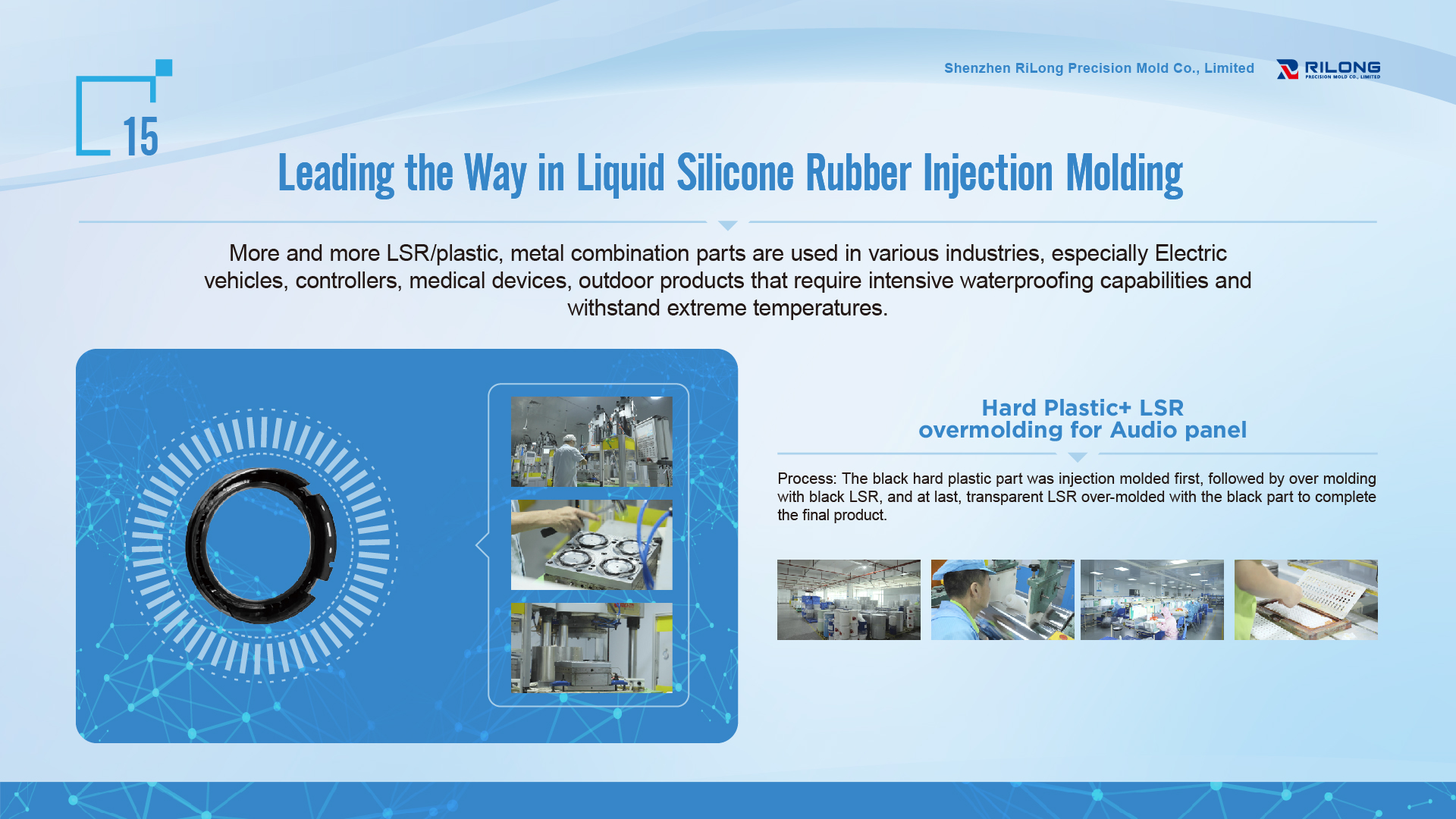

🔹 Overmolding:

- LSR + Plastic – Enhanced grip & sealing (e.g., toothbrush handles)

- LSR + Metal – Vibration-damping, airtight assemblies (e.g., sensor housings)

- LSR + Glass – Medical & optical applications (e.g., lenses, lab equipment)

- LSR + Electronics – Waterproofing & shock absorption (e.g., wearables, connectors)

Our Quality Process

RiLong provides the exceptionally high-quality processes required for healthcare &medical device and Automation products.

RiLong is ISO 9001, ISO14001, ISO 13485, and IATF 16949 certified, and we boast one of the lowest defect rates in our industry.

Why Choose RiLong for LSR Molding?

✔ Advanced equipment – Horizontal, vertical, and two-shot molding options

✔ Material expertise – Custom LSR formulations for medical, automotive & consumer use

✔ Precision & repeatability – Automated mixing, injection, and curing control

Unlock the potential of LSR for your next project!

📩 [Contact RiLong at www.rilong-mold.com, sales1@rilong-mold.com for a Custom Solution]

#LSR #LiquidSiliconeRubber #InjectionMolding #Overmolding #MedTech #PrecisionManufacturing