Mold manufacturing is a complex process, from design, processing, assembly, debugging and other steps, to the final real use. In the whole life cycle, the factors affecting the quality of the tool mainly have the following 10 aspects.

1. Mold steel is the decisive factor of mold quality, and the choice of reasonable steel is the top priority. The steel selection criteria are:

①. Requirements for injection molding materials: different steels shall be selected for different plastics, such as requirements for high polishing surface and corrosion resistance;

②. It is enough to consider the steel with high performance ratio, which does not mean that the more expensive the mold steel is, the better; Considering the cost factor of the mold, the mold steel should be selected with materials corresponding to the mold life to avoid unnecessary waste;

2. Mold structure design. The mature mold structure not only takes into account the product material properties, shrinkage, molding temperature, elastic tensile deformation coefficient, etc., but also takes into account the cooling system, molding cycle speed, etc. The reasonable mold structure can effectively prolong the mold life, ensure the smooth production, improve the efficiency and reduce the cost.

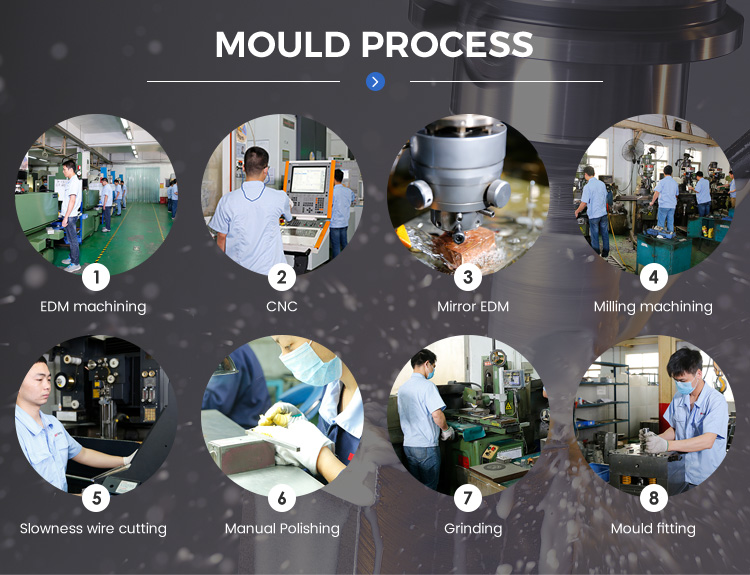

3. Mold processing. The mold process arrangement is particularly important. A reasonable process arrangement can speed up the production cycle, shorten the processing time, and effectively save costs.

4. Mold standard inserts. Although standard parts do not directly participate in forming, they control the operation of the whole mold. Good standard parts should be wear-resistant, hard enough, high precision, and should not be deformed. The price difference of standard parts of different brands is large.

5. Inserts Touching Forming. Seemingly simple work often tests the skills of manufacturer, this part of the processing of complex molds is very important.

6. Polished/Texture. The surface treatment of the mould is the last step in the manufacture of the mould. Polishing is directly reflected in the plastic parts, so this is the most technical work. Polishing can also help and complement the action of the mold.

7. Mold assembly. Mold assembly is like the assembly machine, every component, every screw can not be wrong, otherwise the consequences will be quite serious, it will lead to product defects, affect the production, the most serious word will completely damage the mold, resulting in scrap.

8. Hot /Cold Rubber. actually it has the least effect on mold quality, because hot runner is usually specified.

9. Cooling system. Cooling is very important for a mold. Because of rising prices and labor costs, it is impossible to imagine a profit without cutting a second off the injection molding cycle in mass production. But speeding up the production cycle will increase the temperature of the mold at the same time. If it is not effectively controlled, it will make the mold too hot to form, and even lead to the deformation failure and scrap of the mold. So good cooling design is particularly important, including the layout of the density of cooling, diameter, links between each other and so on.

10. Mould maintenance.It is mainly the maintenance in the production process. The mold is like a car, if it is not used and not maintained for a long time, it may lead to the scrap of the mold. Therefore, after finish the production, comprehensive maintenance should be carried out, especially the rust prevention of the forming part and the rust prevention of the main action parts.