In overmolding projects for consumer electronics, tool handles, sports equipment, and more, the material selection for handle covers directly determines the product’s feel, durability, and user experience. While many assume “silicone is synonymous with soft touch,” TPE/TPU (thermoplastic elastomers) are increasingly becoming the preferred choice for high-end designs due to their unique performance advantages.

We provide two typical samples for direct comparison and testing.

Sample A: TPE (Hardness 50-60 Shore A)

Processing & Sustainability: As a thermoplastic, it is recyclable, with faster production cycles and higher yield rates, making it ideal for sustainable design and cost control.

Surface Finish: No coating, direct molded surface.

Tactile Characteristics: Dry, slightly matte with a fine velvety texture, naturally anti-slip.

Key Advantages:

Dry, Non-Sticky Feel: TPE’s molecular structure is inherently non-tacky, providing a “ready-to-use” grip without additional coatings.

High Resilience & Tear Resistance: Superior recovery after repeated compression and stretching compared to standard silicone, highly resistant to permanent deformation or tearing, ensuring long-term shape stability.

Sample B: Liquid Silicone Rubber (LSR) + Hand Feel Coating

Slightly increases the coefficient of friction for improved grip.

Surface Finish: Sprayed with Hand Feel Coating.

Core Functions of the Coating:

Eliminates the inherent tackiness of silicone—a common issue in uncoated silicone.

Provides a skin-friendly, silky-smooth premium feel.

Enhances surface wear resistance, anti-fouling, and ease of cleaning.

Deep Dive: Why Are the Material Strategies So Different?

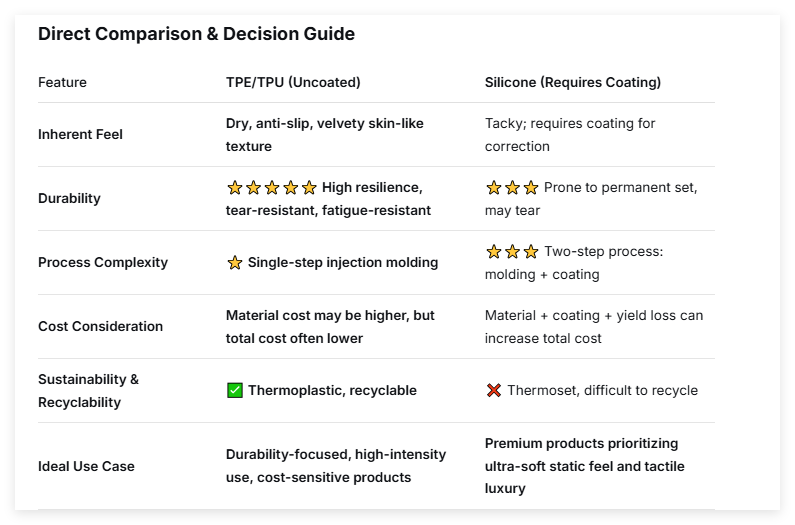

This is not a simple “either-or” choice but a deliberate design strategy targeting different product positioning and user pain points:

The TPE/TPU route, however, embodies a “material as the complete solution” philosophy. Through molecular engineering, it integrates the desired tactile properties (dry, anti-slip feel), mechanical performance (high elasticity, tear resistance), and processing efficiency into a single material. By eliminating reliance on secondary coatings, it simplifies the supply chain, reduces quality risks associated with coating delamination, and delivers durability and resilience that silicone struggles to match. For products subjected to frequent use, significant mechanical stress, or where cost-effectiveness is key—such as tool handles, fitness equipment, or durable electronics—TPE/TPU is often the superior, more professional choice.

The Silicone + Coating route essentially follows a “fix the flaw, then add premium features” approach. While silicone offers excellent softness and biocompatibility, it is naturally sticky, prone to dust attraction, and lacks wear resistance. Thus, the hand feel coating becomes a necessity to achieve basic usability and enhanced tactile quality. This route suits products demanding “ultimate softness and a skin-like feel,” where users are willing to pay a premium for extra finishing—such as high-end gaming controllers or beauty devices.

Conclusion:

The choice depends on the product’s real-world use case and core value proposition.

- If your product is a durable tool meant to withstand repeated squeezing, friction, and sweat, TPE/TPU is the more reliable and professional choice. Its dry grip and robust physical properties are inherent advantages.

- If your product is a high-end consumer electronic device where users prioritize immediate softness and a refined, warm tactile impression with moderate use intensity, the silicone + coating combination delivers a unique luxurious feel.

By offering both samples, we aim to challenge the conventional assumption that “silicone equals softness” and encourage decision-making based on full lifecycle performance, cost, and user experience. Sometimes, the uncoated “raw performance” of a material is the more advanced and durable solution.

Contact us to request samples and experience firsthand the fundamental differences in tactile feel, resilience, and durability between these two materials.