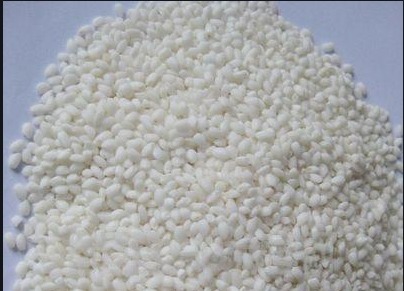

PBT Polybutylene Terephthalate

1. Properties of PBT:

PBT is one of the most rigid engineering thermoplastic materials, it is a semi-crystalline material with excellent chemical stability, mechanical strength, electrical insulation properties, and thermal stability. These materials have good stability in a wide range of environmental conditions, and PBT has a very weak吸湿 characteristic. The tensile strength of the unreinforced PBT is 50MPa, and the tensile strength of the glass-filled PBT is 170MPa. Too much glass addition will make the material brittle.

The crystallization of PBT is very fast, which will cause bending deformation due to uneven cooling. For the glass-filled type materials, the shrinkage in the flow direction can be reduced, but the shrinkage perpendicular to the flow direction is basically the same as that of the ordinary materials.

The general shrinkage rate is between 1.5% and 2.8%. The shrinkage of the material containing 30% glass addition is between 0.3% and 1.6%. The melting point (225℃) and high-temperature deformation temperature are lower than those of PET materials. The Vicat softening temperature is about 170℃. The glass transition temperature (glass trasitiotemperature) is between 22℃ and 43℃.

Because of the high crystallization speed of PBT, its viscosity is very low, and the cycle time of plastic parts processing is generally also lower.

1. Properties of PBT:

PBT is one of the most rigid engineering thermoplastic materials, it is a semi-crystalline material with excellent chemical stability, mechanical strength, electrical insulation properties, and thermal stability. These materials have good stability in a wide range of environmental conditions, and PBT has a very weak吸湿 characteristic. The tensile strength of the unreinforced PBT is 50MPa, and the tensile strength of the glass-filled PBT is 170MPa. Too much glass addition will make the material brittle.

The crystallization of PBT is very fast, which will cause bending deformation due to uneven cooling. For the glass-filled type materials, the shrinkage in the flow direction can be reduced, but the shrinkage perpendicular to the flow direction is basically the same as that of the ordinary materials.

The general shrinkage rate is between 1.5% and 2.8%. The shrinkage of the material containing 30% glass addition is between 0.3% and 1.6%. The melting point (225℃) and high-temperature deformation temperature are lower than those of PET materials. The Vicat softening temperature is about 170℃. The glass transition temperature (glass trasitiotemperature) is between 22℃ and 43℃.

Because of the high crystallization speed of PBT, its viscosity is very low, and the cycle time of plastic parts processing is generally also lower.

2. Processing characteristics of PBT

Drying treatment: This material is easily hydrolyzed at high temperatures, so drying treatment before processing is very important. The recommended drying conditions in air are 120℃, 6-8 hours, or 150℃, 2-4 hours.

The moisture content must be less than 0.03%. If drying is performed using a desiccant dryer, the recommended conditions are 150℃, 2.5 hours. The processing temperature is 225~275℃, and the recommended temperature is 250℃. For the unreinforced material, the mold temperature is 40~60