Durable and visually appealing surfaces not only enhance product aesthetics but also build customer trust. Electroplating deposits a thin metal layer on plastic or metal parts, providing corrosion resistance, wear resistance, durability, and premium finishes. This makes it ideal for electronics, automotive, and consumer products.

How Electroplating Works

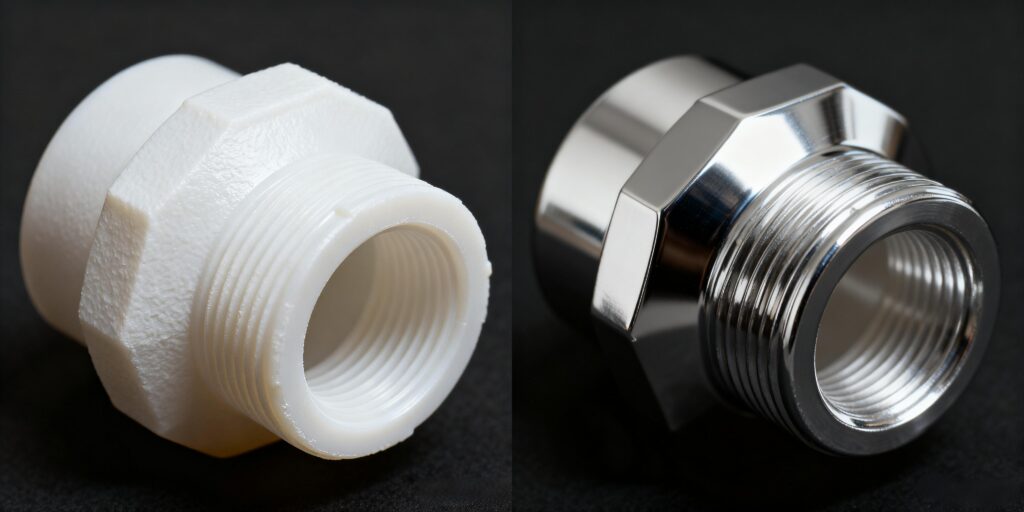

Plastic Parts

Plastic components first receive a conductive coating and then undergo metal plating (copper, nickel, chrome), achieving a metallic appearance while maintaining structural integrity.

Metal Parts

Metal components are cleaned and directly plated, improving corrosion resistance, wear resistance, and visual appeal.

Benefits of Electroplating

| Feature | Plastic Parts | Metal Parts |

|---|---|---|

| Durability | Corrosion & wear resistant | Corrosion & wear resistant |

| Appearance | Premium metallic look | Shiny, high-end finish |

| Functionality | Enhances wear resistance & conductivity | Enhances wear resistance & corrosion protection |

| Automation Ready | Supports automated production | Supports automated production |

Applications

Metal Parts: Mechanical components, electronic housings, consumer products

Plastic Parts: Automotive interior trims, phone cases, appliance panels

Why OEMs Choose Electroplating

- Premium surface finish enhances product value

- Improves durability and functional performance

- Suitable for both plastic and metal components

- Compatible with automated mass production

One-Stop Service Advantages

We offer end-to-end services: design optimization, mold making, injection molding, rubber molding, metal fabrication, secondary processing, and assembly — ensuring every part is high-quality and visually appealing.

Call-to-Action (CTA)

Whether you need metallic finishes on plastic parts or durable coatings on metal components, we provide professional electroplating solutions.

Contact us today for a custom quote!