RiLong specialize in the custom design and manufacturing of high-performance fiber optic connector boots. Our expertise lies in engineering precision injection molds and mastering the production process to deliver boots that excel in performance, safety, and reliability.

Image Box Title

Change this description

- Superior TPE Material for Demanding Applications

We use premium Thermoplastic Elastomer (TPE) for its unique combination of properties:

Exceptional Safety: Our TPE compound is rigorously tested and complies with the UL 94 V-0 flame retardancy standard. This highest rating ensures maximum safety for sensitive applications in data centers, enterprise networks, and industrial settings.

Durability & Flexibility: TPE offers excellent elasticity, tear resistance, and longevity. Our boots provide superior strain relief, withstand repeated mating cycles, and resist cracking, ensuring lasting protection for the fiber.

Environmental Resistance: The material is formulated to perform reliably across a wide temperature range and resist exposure to chemicals, UV light, and moisture.

- Custom Mold Design & Engineering

The perfect boot starts with a perfect mold. Our in-house mold design and fabrication capabilities allow for:

Full Customization: We tailor boots to your exact specifications—interface type (LC, SC, MPO, etc.), locking mechanism, cable entry style, and branding.

Precision Engineering: Our molds are built for high-precision, flash-free manufacturing, ensuring consistent dimensions, perfect fit, and excellent sealing with your connector assembly.

Rapid Prototyping: We accelerate your development cycle with quick turnaround on prototypes, getting you from concept to sample faster.

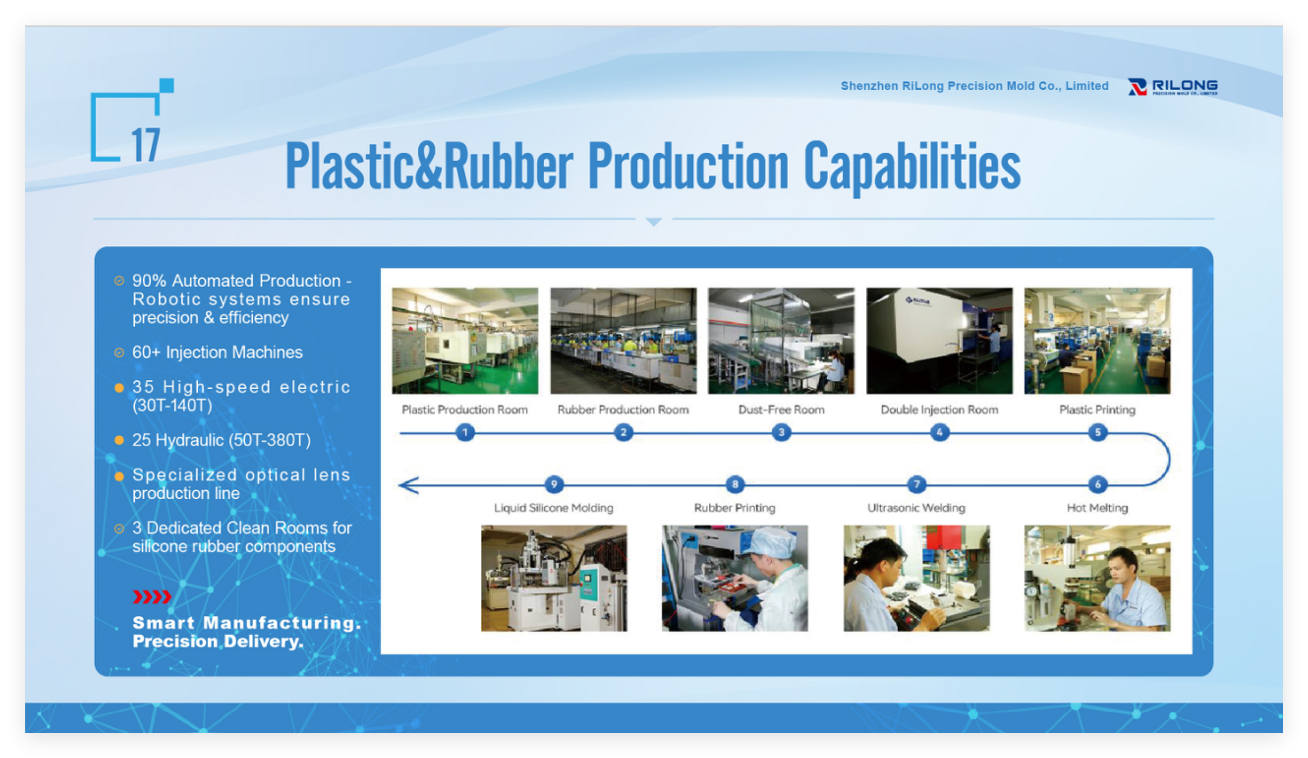

- High-Volume, Quality-Driven Production

Our manufacturing process is built for quality and scale:

Automated Injection Molding: We utilize advanced, fully automated injection molding systems to produce large volumes with unmatched consistency and efficiency.

Stringent Quality Control: Every production run is supported by rigorous process controls and 100% inline inspection to guarantee every boot meets our exacting standards for dimensions and appearance.

Your Partner for Critical Components

We are more than a supplier; we are a solutions partner. We provide the technical expertise to bring your custom boot design to life with a commitment to quality, reliability, and performance.

Interested in learning how our custom TPE boots can enhance your fiber optic connectors? Contact our engineering team today to discuss your requirements and request samples.