Our Services

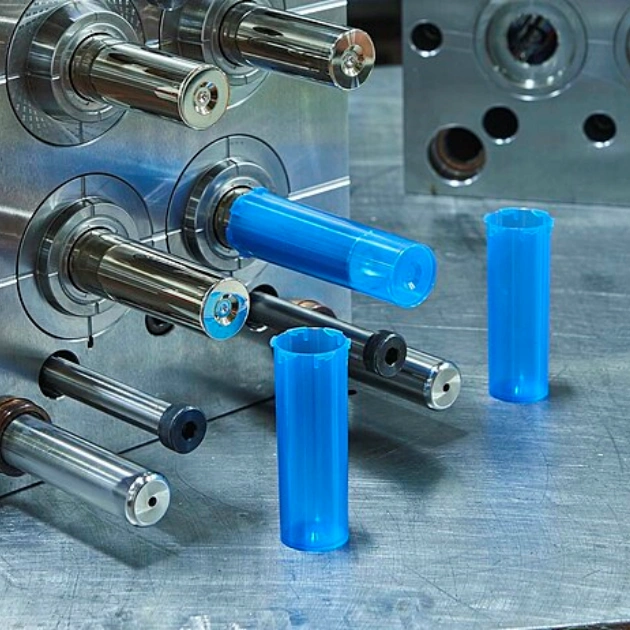

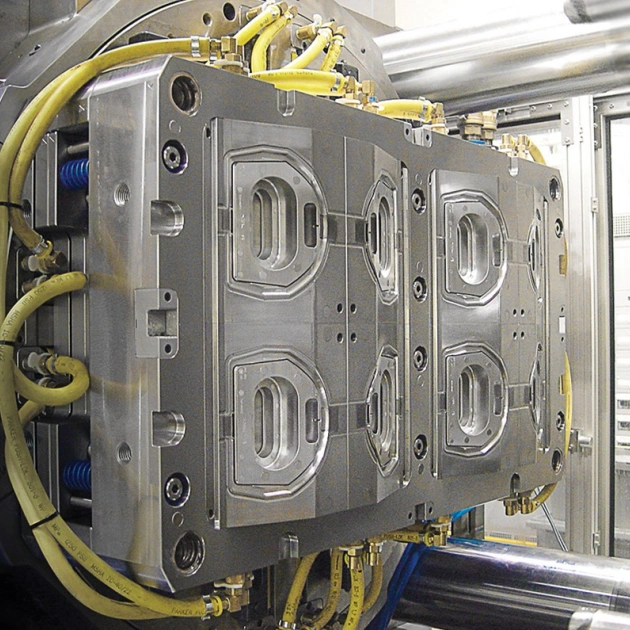

Rilong Precision Mold is a full-service supplier of engineering services, product design and integration, and contract manufacturing of a wide variety of injection molded components and subassemblies.

0

years of

experience

experience

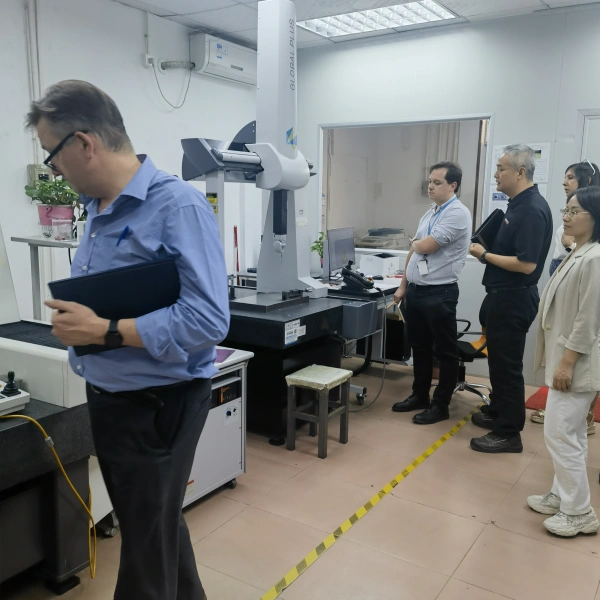

Our Factory

RiLong Precision Mold Company was established in 1990 in Shenzhen, as an original supplier of high-precision plastic injection parts mainly exported to the US and Japan.

Currently employs 300 skilled and experienced staff members to work in engineering, production, inspection, and QC units.

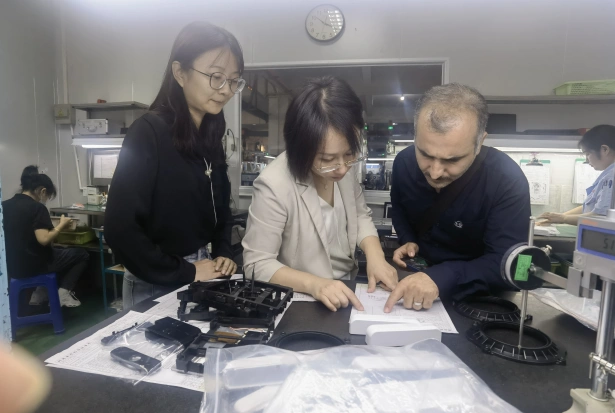

Contract Manufacturing

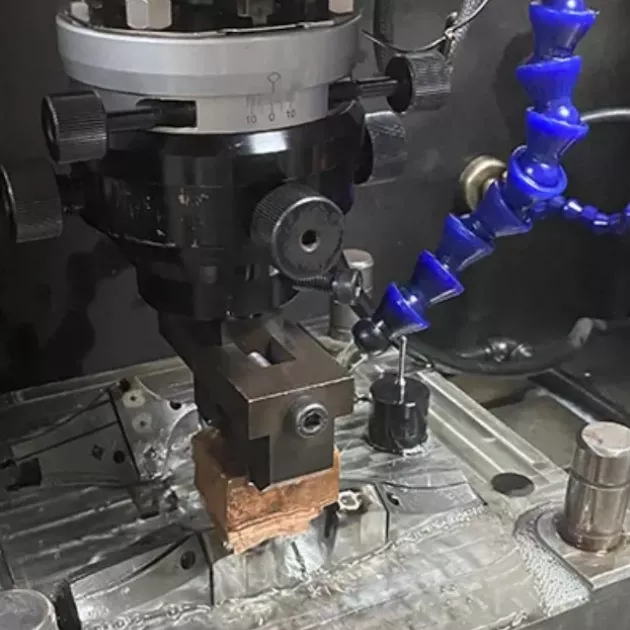

We provide an extensive array of processing techniques for both metal and plastic components.

We will answer any of your questions

0

Best Price

Low-Volume Manufacturing

As fast as 1 day

Mass Production

Top-grade equipment

Quality Guarantee

Rilong, an ISO 9001:2015 and ISO 13485-certified plastic injection molding company in Shenzhen, exceeds industry standards to deliver exceptional quality. Our rigorous processes guarantee the timely delivery of high-quality plastic products tailored to your company’s needs. We also maintain AS9100 compliance, FDA registration, an active CAGE Code, and ATF FFL registration. Additionally, we regularly test our products to UL, CE, and FCC standards through third-party partners, ensuring the utmost reliability and performance.

We adhere to the following quality systems:

1. ISO9001 – Quality Management

2. ISO14001 – Environmental Management

3. IATF16949 – Automotive Industry Quality Management Standard

4. 6S Managing system –SEIRI, SEITON, SEISO, SEIKETSU, SHITSUKE

5. All of the materials are compatible with RoHs and Reach certifications.

1. ISO9001 – Quality Management

2. ISO14001 – Environmental Management

3. IATF16949 – Automotive Industry Quality Management Standard

4. 6S Managing system –SEIRI, SEITON, SEISO, SEIKETSU, SHITSUKE

5. All of the materials are compatible with RoHs and Reach certifications.

0

+

0

+

Measuring Devices

Success Projects

ISO 9001, ISO 14001, IATF 1694, AND UL-CERTIFIED FACTORIES

Our Recent Projects

Hair Styling Tool

We helped our US customers create a hair styling device from design optimization to production and packaging. The device includes over 10 plastic parts, with optimized designs for manufacturability. We also collaborated to produce discs with crystals. Despite initial challenges, our production lines now run smoothly, yielding 20,000 units per month.

Note: In respect of confidentiality and under the terms of a Non-Disclosure Agreement (NDA) with our customer, product logos have been omitted.

Why Choose Us

Delivering Innovation Since Inception Years