About Us

Pioneering and Growth

Delivering Innovation Since Inception Years

About us

Rilong was founded in 1990 in Shenzhen as a premier supplier of high-precision plastic injection parts, primarily exporting to the US and Japan. With technological innovation and professional manufacturing capability, since being put into operation, Rilong has grown steadily, gathered a group of professionals and Top global partners, and established a long-term partnership with the Hong Kong Polytechnic University.

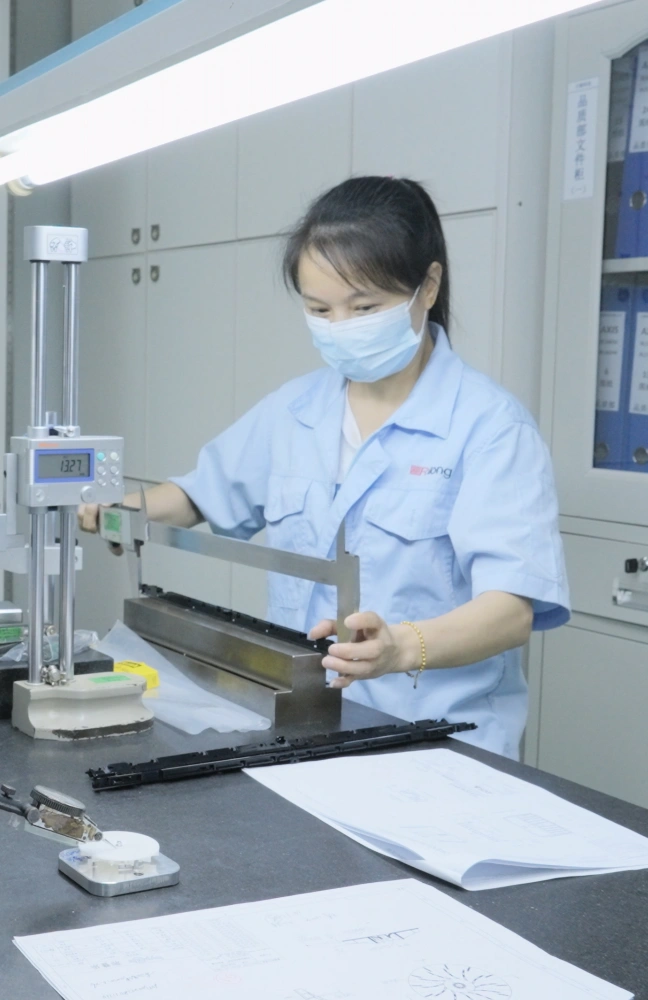

Currently, we employ 300 skilled and experienced staff members across our engineering, production, inspection, and quality control units. With a team of over 30 professional R&D experts, we consistently provide our customers with comprehensive, 100% in-house manufacturing solutions for their product development needs.

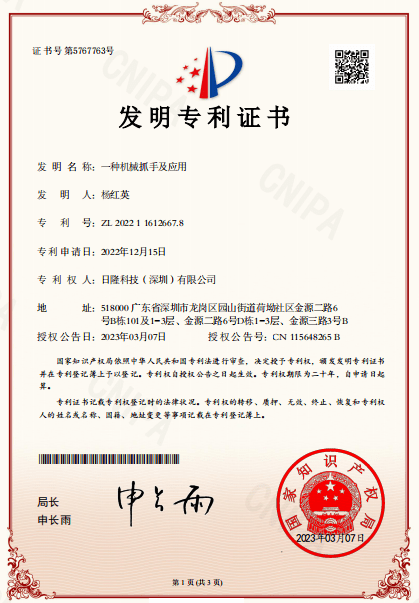

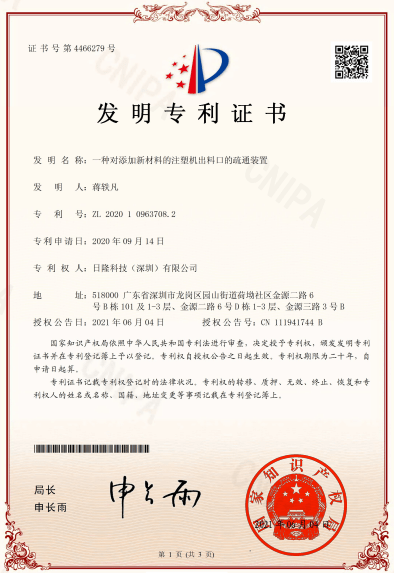

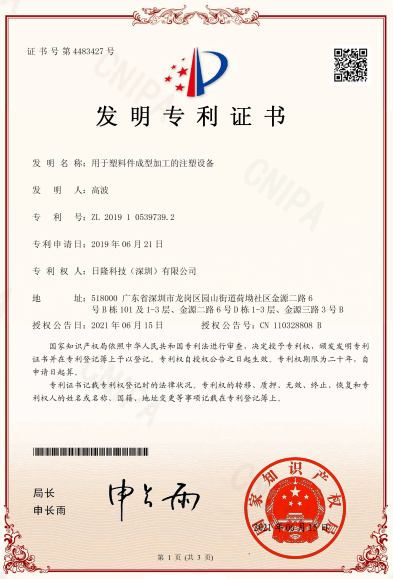

Rilong prioritizes technological innovation and regularly updates and optimizes its equipment. Recognized as a high-tech enterprise by the state, RiLong has earned four invention patents and 28 utility model patents.

Currently, we employ 300 skilled and experienced staff members across our engineering, production, inspection, and quality control units. With a team of over 30 professional R&D experts, we consistently provide our customers with comprehensive, 100% in-house manufacturing solutions for their product development needs.

Rilong prioritizes technological innovation and regularly updates and optimizes its equipment. Recognized as a high-tech enterprise by the state, RiLong has earned four invention patents and 28 utility model patents.

Quality Assurance

We ardently uphold our dedication to rigorous performance metrics, which are firmly entrenched and diligently adhered to across all organizational domains.

The key factor in helping us to maintain our high quality is the use of the following quality systems throughout all of our business in the factory.

• ISO9001:2015 – Quality Management

• ISO14001:2015 – Environmental Management

• IATF16949:2016 – Automotive Industry Quality Management Standard

• Implement 7S Management System Through our Factory

All of the materials are compatible with RoHs and Reach certifications

The key factor in helping us to maintain our high quality is the use of the following quality systems throughout all of our business in the factory.

• ISO9001:2015 – Quality Management

• ISO14001:2015 – Environmental Management

• IATF16949:2016 – Automotive Industry Quality Management Standard

• Implement 7S Management System Through our Factory

All of the materials are compatible with RoHs and Reach certifications

99.7%

Part Acceptance

Part Acceptance

99.9%

Safe Production

Safe Production

• Multifaceted measurement

• Impact testing

• Specialized fixtures

• Production logs and accountability

• Impact testing

• Specialized fixtures

• Production logs and accountability

• Regular safety production training

• An effective safety system

• Regular equipment maintenance

• Emergency plan execution

• An effective safety system

• Regular equipment maintenance

• Emergency plan execution

0

Years of experience

Our dedication ensures that Rilong remains at the forefront of manufacturing innovation, consistently delivering quality and reliability to our clients.

0

Served Countries

We have established a strong presence in over 50 developed countries, including the United States, Japan, and the UK.

0

Advanced Machines

Rilong selects machinery from global leaders to enhance our manufacturing capabilities, setting new standards for precision and excellence.

0

Completed Projects

Our project strength encompasses a range of specialized departments, from engineering to design, and quality control to management.

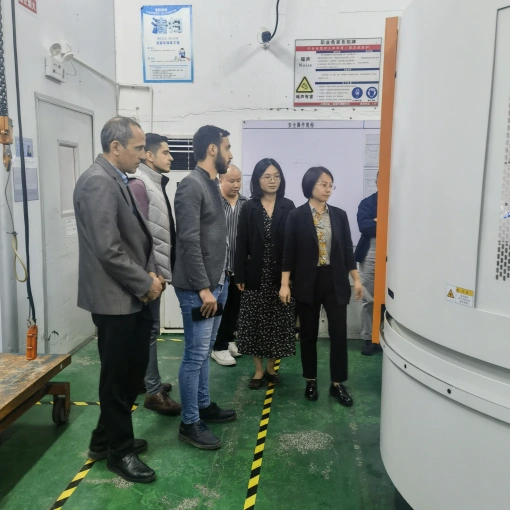

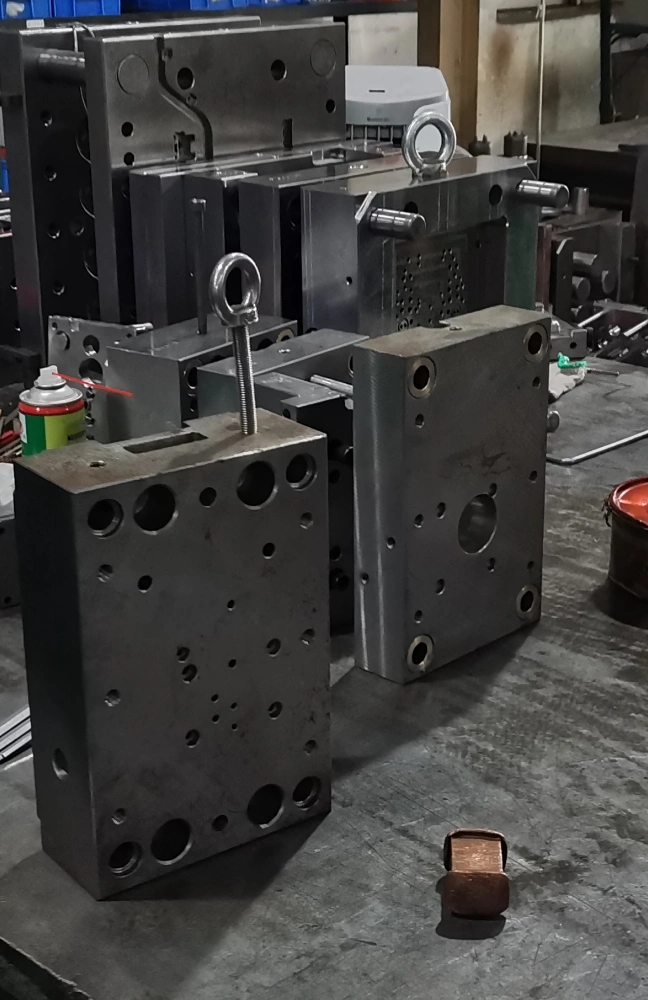

Tour our Injection Molding Facility

Take a quick peek behind the curtain of our injection molding process. We offer a fully digitized injection molding process to bring your cost-efficient parts fast.

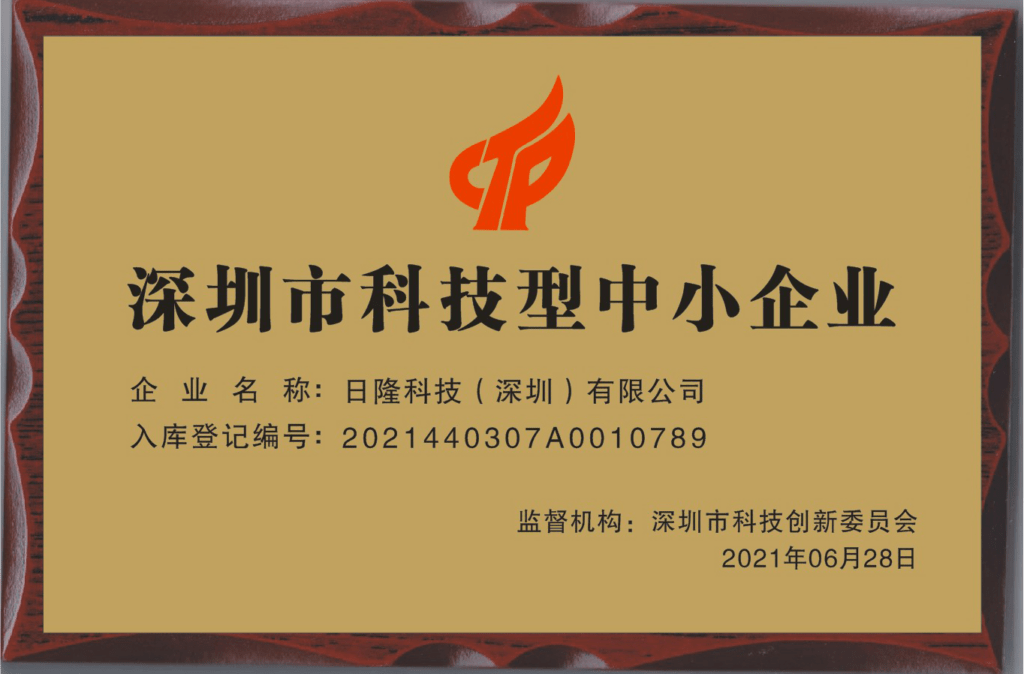

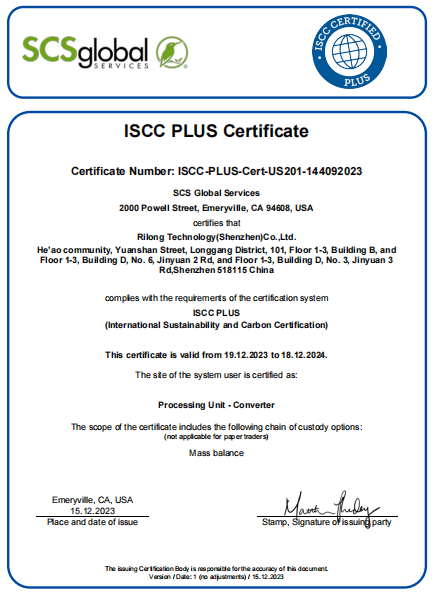

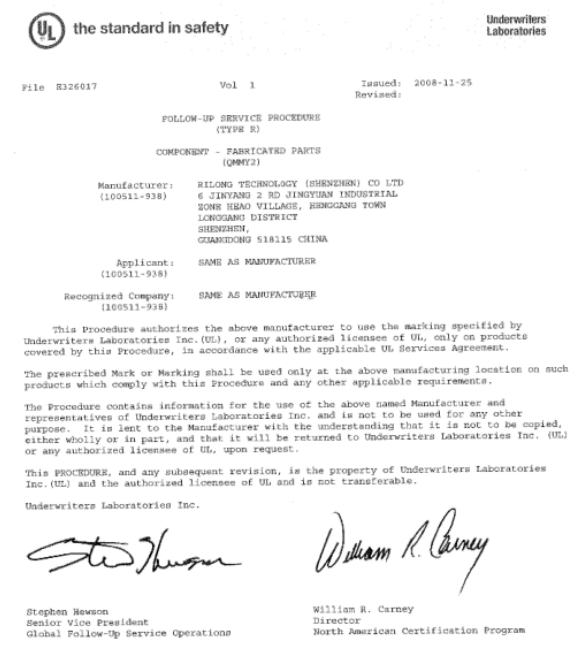

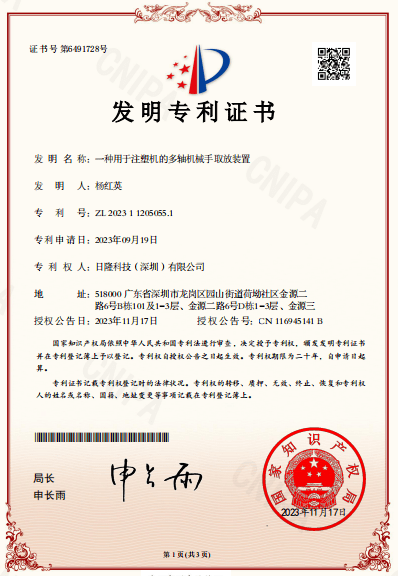

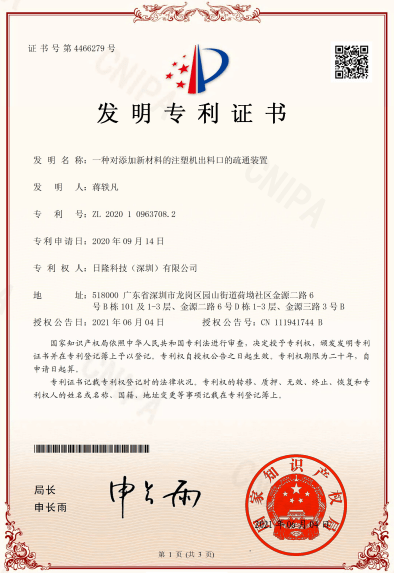

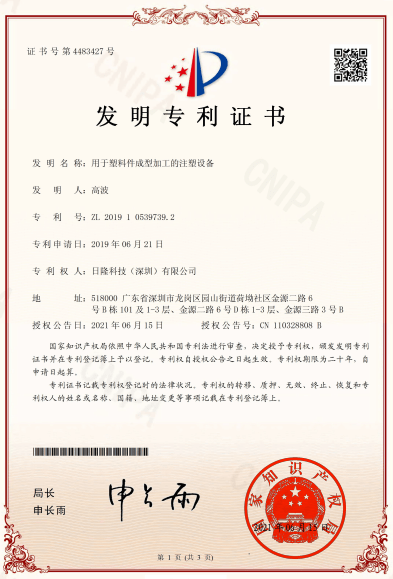

Recipient of multiple qualifications and patent certificates

Superior Injection Mold Design And Manufacturing

Enterprise certificate

Awarded various professional certificates, including the High-Tech Enterprise Certificate issued by the Shenzhen Municipal Government and the Certificate of Director Enterprise of the Mold Professional Committee of the Machinery Industry Association.

Social:

International Quality Systems Certificates

We have international ISO and Medical ISO 13485 certificates

-plastic-house_ENG.webp)

Social:

Innovative R & D Patent Certificate

We have several innovative R&D patents for medical products and electronic products

Social:

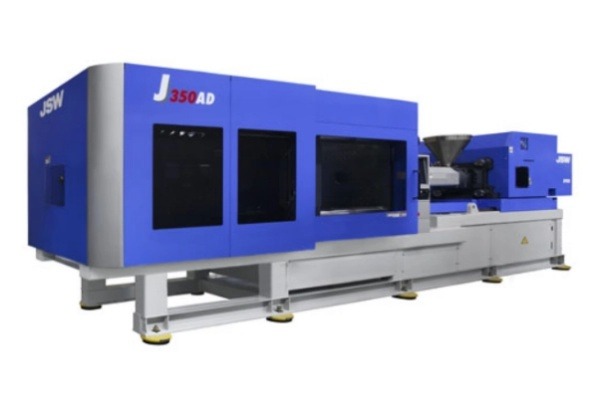

Advanced Equipment

Leading-edge Processing & Inspection machines guarantee High Precision good Quality injection mold and molding products.

Social:

The manufacturing department has a total of 54 injection molding machines, with injection tonnage: 30-380 tons.

We have a dust-free workshop, specializing in the production of lenses and transparent products.

Here is a partial list of our main equipment:

We have a dust-free workshop, specializing in the production of lenses and transparent products.

Here is a partial list of our main equipment:

PRODUCTION EQUIPMENT:

• CHARMILLES,SEIKI,MITSUBISHI CNCs

• CHARMILLES,SODICK EDMs

• CHARMILLES,SODICK WEDMs

• SUMITOMO, JSW, NISSEI, SANYO, etc, Hi-speed electro-motion injection machines

• Dust-free workshop for producing Lens and transparent products

• KENT 4-color Full-automatic Pad spring machine

• Laser Engrave machine

• silkscreen printing assembly line

• Painting assembly line

• CHARMILLES,SEIKI,MITSUBISHI CNCs

• CHARMILLES,SODICK EDMs

• CHARMILLES,SODICK WEDMs

• SUMITOMO, JSW, NISSEI, SANYO, etc, Hi-speed electro-motion injection machines

• Dust-free workshop for producing Lens and transparent products

• KENT 4-color Full-automatic Pad spring machine

• Laser Engrave machine

• silkscreen printing assembly line

• Painting assembly line

TESTING EQUIPMENT:

• CMM-Coordinate Measuring Machines

• Mesh GEAR TESTER

• Color Difference Instrument

• VMS-Video Measuring Systems

• Tool Microscopes

• CMM-Coordinate Measuring Machines

• Mesh GEAR TESTER

• Color Difference Instrument

• VMS-Video Measuring Systems

• Tool Microscopes

The global network of manufacturing partners

We provide OEM assembly, precision mold manufacturing, injection molding, and silicone rubber molding for global customers;

Among them, American customers account for 40%; European customers account for 40%; Oceania and Asia customers account for 20%.

Among them, American customers account for 40%; European customers account for 40%; Oceania and Asia customers account for 20%.