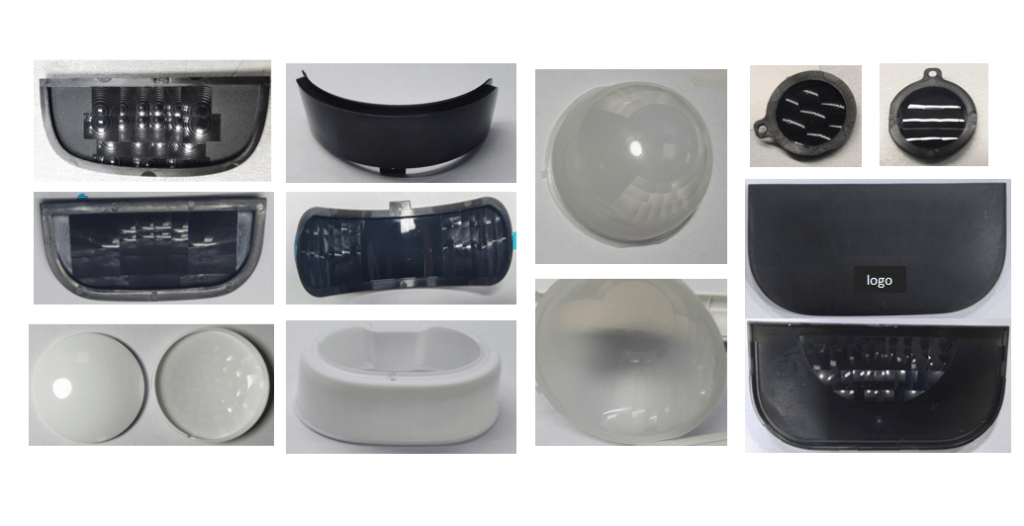

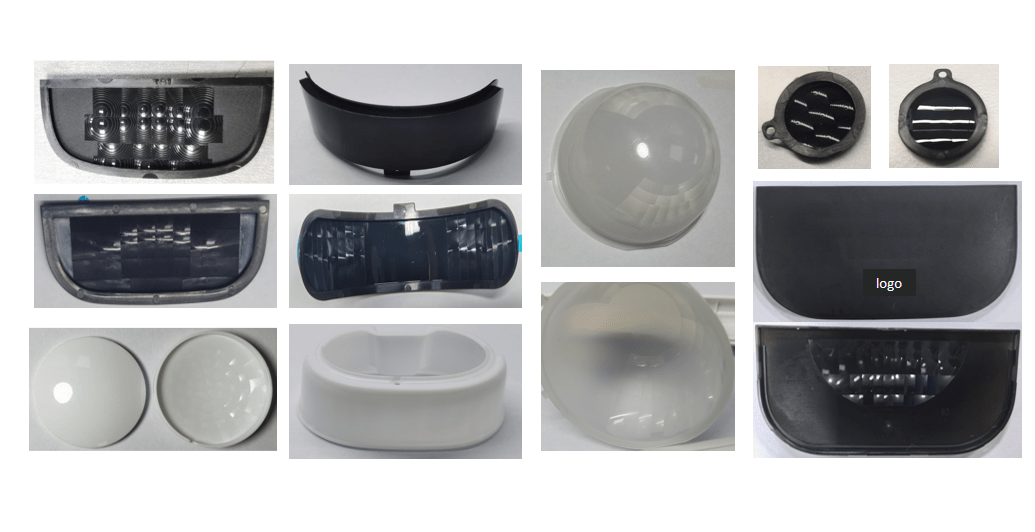

PIR Lens, also known as a Fresnel lens, is a thin sheet made of a polyolefin material by injection molding. Its surface has one side with a polished finish and the other side with concentric circles of varying sizes, which is a texture designed to take advantage of the dry friction and diffraction of light and based on relative sensitivity and reception angle requirements. The characteristics of the Fresnel lens include a large surface area, thin thickness, and a long detection distance.

The Fresnel lens has two main functions: one is the focusing function, which refracts (reflects) the thermal infrared signal onto the PIR; the other is to divide the detection area into several bright and dark zones, so that moving objects entering the detection area can produce temperature change-related infrared signals on the PIR.

The teeth pattern design of the Fresnel lens allows it to achieve a bandpass (reflection or refraction) effect for a specified spectral range of light. For example, in a passive infrared (PIR) detector, the Fresnel lens can limit the frequency peak of the incident light to around 10 microns (the peak of human infrared radiation), thus achieving focusing and sensing of the human body’s thermal infrared signal.

he Fresnel lens is the “eyeglasses” of the infrared sensor. Its proper use or improper use will directly affect the effectiveness of use. If used properly, it can fully utilize the function of human body sensing, expanding its application field. On the other hand, if used improperly, it may cause false actions and missed actions, making the user lose confidence in it.

Additionally, the manufacturing process of the Fresnel lens is also an important factor in its performance. It is usually made of organic glass and cannot be cleaned with any organic solvents such as alcohol. To clean it, you can first rinse it with distilled water or regular tap water, then wipe it with a cotton swab.

In summary, the Fresnel lens is an important optical component that has widespread applications in fields such as passive infrared detection. Its working principle and manufacturing process have important impacts on its performance and applications.