Material Selection: The Cornerstone of Performance and Safety in Medical Devices

In the medical device industry, material selection is fundamental to product performance, safety, and ultimate success. As your trusted partner, [RiLong Precision Mold] is committed to providing comprehensive medical silicone solutions—from conceptual design and R&D to full-scale production. We deeply understand the stringent demands of medical-grade applications and translate this commitment into reality through our exceptional product attributes.

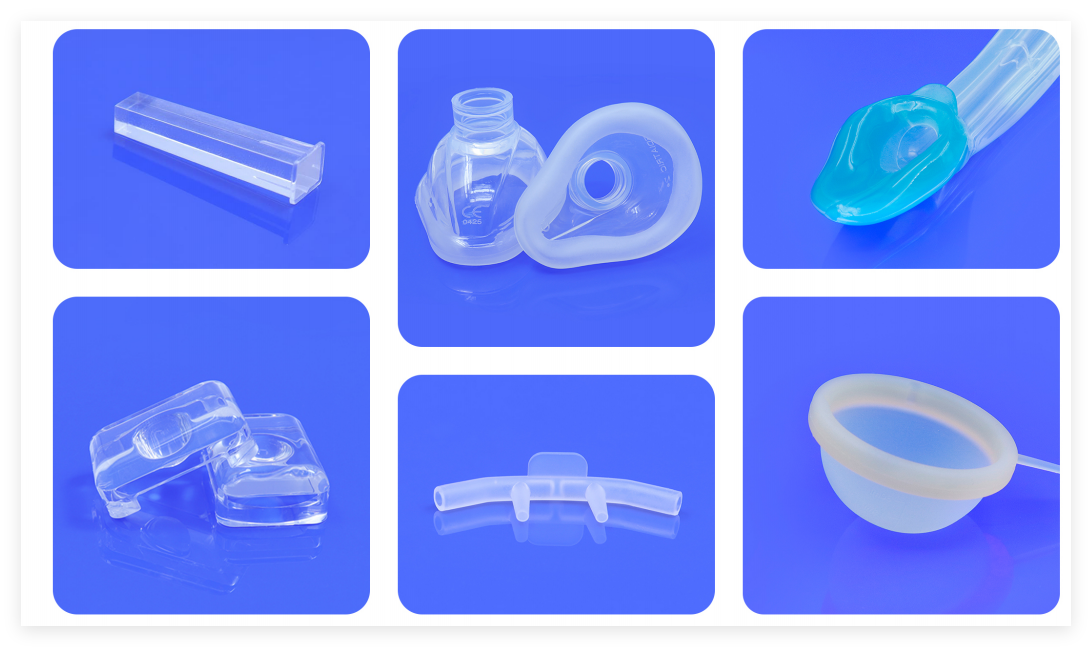

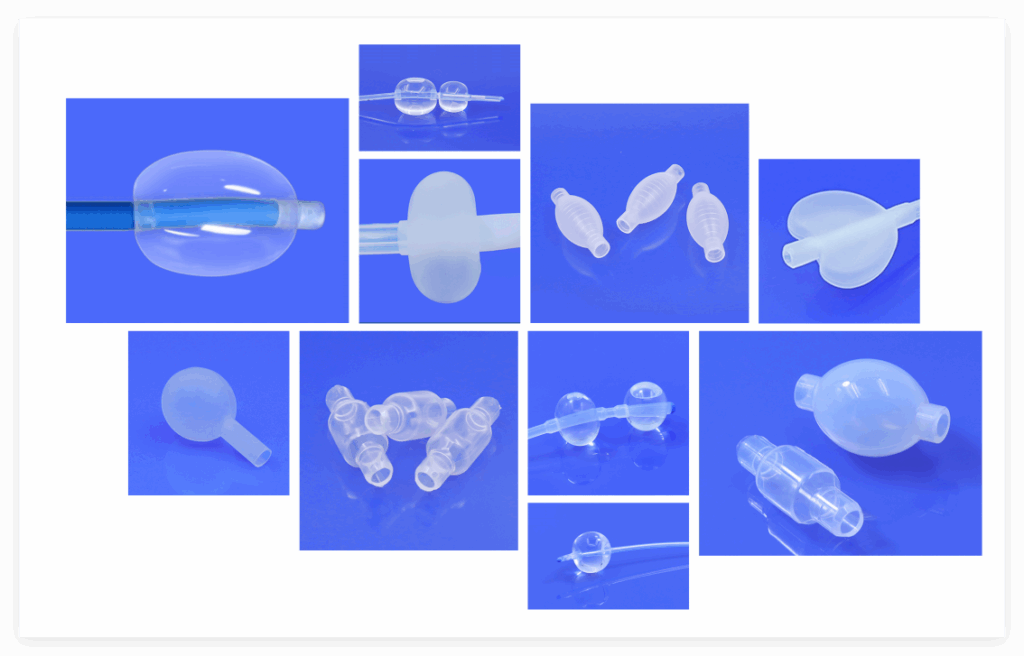

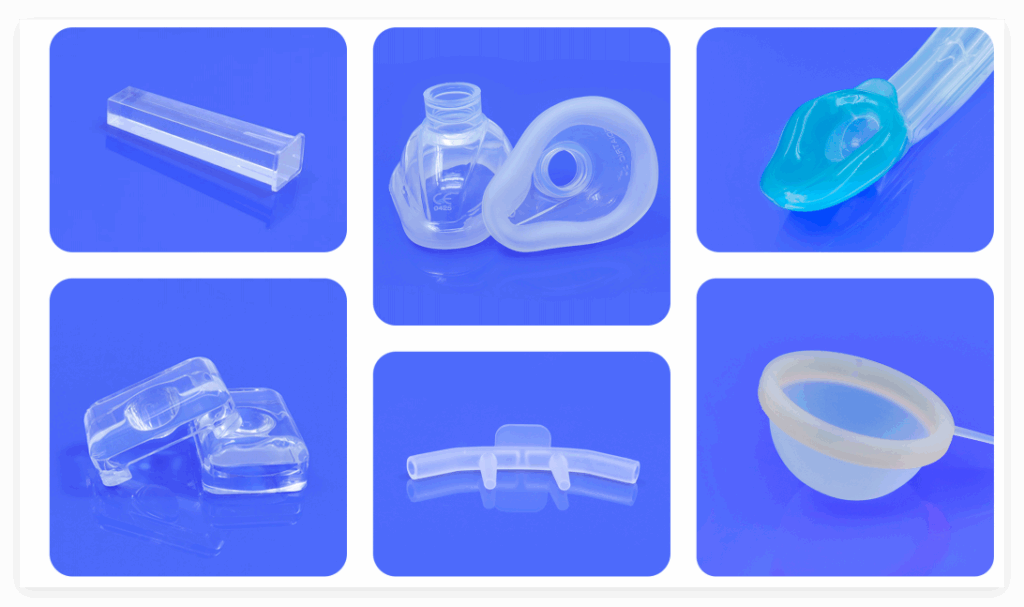

Core Advantages of Our Medical Silicone Products

Our products are designed not just to meet standards, but to exceed expectations. Here’s how our materials add value to your devices:

Excellent Biocompatibility

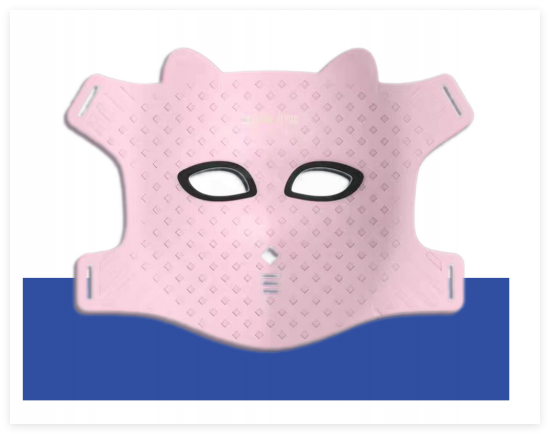

We rigorously select and utilize medically-grade silicone raw materials that pass comprehensive biocompatibility testing. This ensures high compatibility with human tissues and body fluids, significantly reducing the risk of potential irritation and allergic reactions. It provides a solid foundation for patient safety, giving you peace of mind when designing implants, wearable devices, or long-term contact products.

Superior Softness and Elasticity

We understand that medical devices must adapt to complex ergonomic requirements. Our silicone products offer excellent softness and resilience, conforming perfectly to various body curves and shapes. This not only enhances patient comfort but also ensures the functional stability and effectiveness of the device.

Strong Chemical Resistance

In hospital and laboratory environments, devices are frequently exposed to various disinfectants and chemicals. Our medical silicone products exhibit outstanding chemical stability, withstanding exposure to many common chemical substances. This guarantees consistent performance without degradation through repeated sterilization and use, thereby extending the product’s service life.

Exceptional Abrasion and Oxidation Resistance

Long-term durability is key to medical device reliability. Our silicone products possess high resistance to wear and oxidation, effectively resisting aging, hardening, or cracking even after prolonged use. This ensures consistent performance throughout the device’s lifecycle and reduces failure rates.

Why Choose Our End-to-End Service?

With over 20 years as China’s foremost silicone molding innovator, Rilong Precision Mold Company delivers industry-leading molding expertise both in hot compression molding and LSR injection molding, backed by:

Proprietary material formulations for superior performance

Precision engineering capabilities for complex geometries

Certified manufacturing processes (ISO9001,ISO14001,ISO13485, TS16949,, FDA, etc.)

R&D-driven solutions for mission-critical applications

Accelerated Time-to-Market: By leveraging our integrated internal resources, we can effectively shorten your product development cycle, helping you bring innovative ideas to market faster.

We look forward to partnering with you to turn the next medical innovation into reality.

Contact us to learn more or discuss your custom project

www.rilongsilicone.com

Seamless Collaboration: We are involved throughout the entire process, from initial design concepts and material selection to complex prototyping and precision manufacturing.

Quality Assurance: We implement a strict quality management system throughout the entire production process, ensuring every product shipped meets the highest industry standards.