ABS is one of the most commonly used thermoplastics in injection molding, widely appreciated for its excellent mechanical properties and versatility. Injection molding of ABS is a vital process in manufacturing various durable and impact-resistant products, from automotive parts to electronic housings and consumer goods. This blog will explore the essentials of ABS injection molding, its benefits, applications, and key considerations for successful production.

What is ABS?

ABS is a thermoplastic polymer known for its excellent mechanical properties. It combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber. It is composed of three main components:

- Acrylonitrile: Provides chemical resistance and heat stability.

- Butadiene: Adds toughness and impact resistance.

- Styrene: Offers rigidity and a glossy finish.

The combination of these three monomers results in a material that is lightweight, durable, and easy to process, making it ideal for injection molding.

Advantages of ABS Injection Molding

- Excellent Mechanical Properties: ABS offers a unique balance of rigidity, toughness, and impact resistance. This makes it suitable for products requiring durability, such as protective casings, helmets, and automotive parts.

- Chemical Resistance: ABS is resistant to many chemicals, making it suitable for applications in harsh environments.

- Easy to Mold: ABS is a low-cost material ability to produce complex geometries, allowing for complex shapes and fine details in molded parts. Its high flow characteristics make it a favorite among manufacturers.

- Surface Finishing Options: ABS can be easily painted, glued, or plated with metals, providing flexibility in product design and aesthetics.

- Cost Efficiency: ABS is relatively inexpensive compared to other engineering plastics like polycarbonate or nylon, offering a cost-effective solution for manufacturers while delivering high-quality parts.

- Fast Production: Injection molding allows for rapid production of parts, reducing lead times.

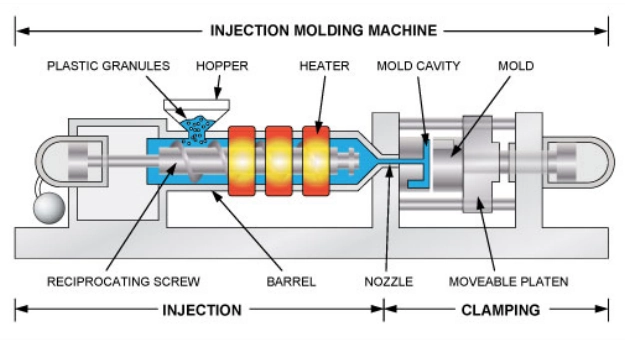

The ABS Injection Molding Process

Step 1: Material Preparation ABS pellets are first dried to remove moisture, which can affect the final quality of the product. Typical drying temperatures are between 80°C and 90°C for 2-4 hours. Proper drying prevents defects like splay marks, bubbles, or weak mechanical properties in the molded parts.

Step 2: Melting and Injection Once dried, the ABS pellets are fed into the hopper of the injection molding machine. The material is heated until it reaches a molten state, usually between 200°C to 250°C, depending on the specific grade of ABS. The molten plastic is then injected into a mold cavity under high pressure.

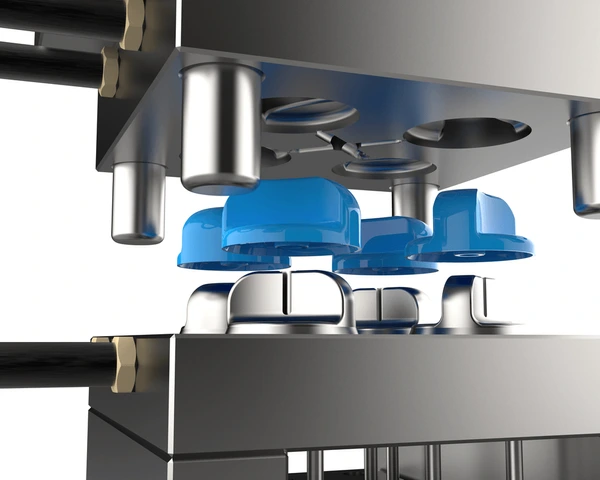

Step 3: Mold Cooling and Solidification As the ABS fills the mold cavity, it begins to cool and solidify. Cooling time varies based on the complexity of the part, thickness, and mold design, but typically takes a few seconds to minutes. Proper mold temperature control is critical to ensure that the part cools evenly and avoids warping or other defects.

Step 4: Ejection Once the part has cooled and solidified, it is ejected from the mold. The cycle is then repeated for continuous production.

Common Applications of ABS Injection Molding

ABS injection molding is widely used across various industries due to its excellent properties. Some common applications include:

- Automotive Industry: Interior components, dashboards, and trim parts.

- Consumer Electronics: Housings for televisions, computers, and mobile devices.

- Appliances: Vacuum cleaners, kitchen appliances, and enclosures.

- Toys: Durable, impact-resistant toys like LEGO bricks are made from ABS.

- Medical Devices: Enclosures and housings for medical equipment.

Key Considerations for ABS Injection Molding

- Proper Mold Design: Mold design is critical in ensuring the quality and consistency of ABS molded parts. Proper gating, venting, and cooling channels must be implemented to avoid defects such as sink marks, warping, or incomplete filling.

- Processing Conditions: Precise control of temperature, pressure, and injection speed is necessary for optimal results. Too high of a temperature can lead to degradation, while too low a temperature may cause poor flow and incomplete fills.

- Shrinkage and Warping: ABS parts typically exhibit low shrinkage rates, but warping can occur if cooling is not uniform. Careful control of mold temperature and cooling time is essential to ensure dimensional stability.

- Post-Molding Operations: While ABS parts usually come out of the mold with excellent surface finishes, additional post-processing steps such as painting, plating, or assembly may be required to meet specific design requirements.

Challenges and Considerations

While ABS injection molding offers many advantages, there are some challenges to consider:

- High initial tooling costs

- Potential for warping or sink marks if not properly designed

- Need for proper ventilation due to styrene emissions during processing

- Sensitivity to UV radiation, requiring additives for outdoor applications

Future Trends in ABS Injection Molding

The field of ABS injection molding continues to evolve, with several exciting trends on the horizon:

- Integration of AI and machine learning for process optimization

- Development of more environmentally friendly ABS formulations

- Advancements in mold design for improved efficiency and part quality

- Increased use of recycled ABS in injection molding processes

Conclusion

ABS injection molding is an indispensable process in modern manufacturing, offering a perfect blend of durability, flexibility, and cost-effectiveness. With proper material handling, mold design, and process control, ABS can be molded into high-quality, precision-engineered parts used in a wide variety of applications. Whether you’re producing automotive components, consumer electronics, or everyday household items, ABS injection molding provides the versatility and performance needed to meet demanding production goals.