Mastering Three-Dimensional Precision | Comprehensive Metrology Solutions for Your Critical Dimensions

In the pursuit of manufacturing excellence, every leap in precision begins with uncompromising measurement of the smallest details. We are dedicated to providing global clients with comprehensive precision metrology solutions, ensuring every component—from mold to final product—meets the most stringent…

Beyond Making New Molds: We Also Welcome Your Existing Tooling for Production

At Rilong Precision Mold, we understand the value of your tooling assets. Whether you already have a proven mold or are planning a new project, we are committed to being your reliable manufacturing partner. We not only provide custom new…

Handle Cover Material Showdown: Silicone vs. TPE/TPU—Why We Offer Two Different Solutions?

In overmolding projects for consumer electronics, tool handles, sports equipment, and more, the material selection for handle covers directly determines the product’s feel, durability, and user experience. While many assume “silicone is synonymous with soft touch,” TPE/TPU (thermoplastic elastomers) are increasingly becoming the preferred…

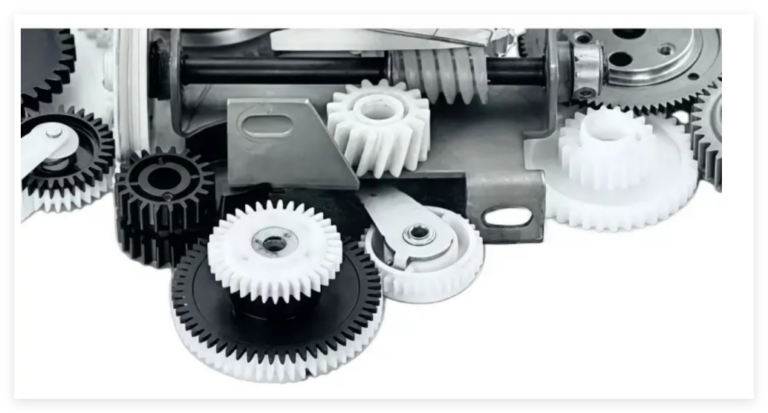

Innovate with Confidence: End-to-End Medical Silicone Solutions

Material Selection: The Cornerstone of Performance and Safety in Medical Devices In the medical device industry, material selection is fundamental to product performance, safety, and ultimate success. As your trusted partner, [RiLong Precision Mold] is committed to providing comprehensive medical…

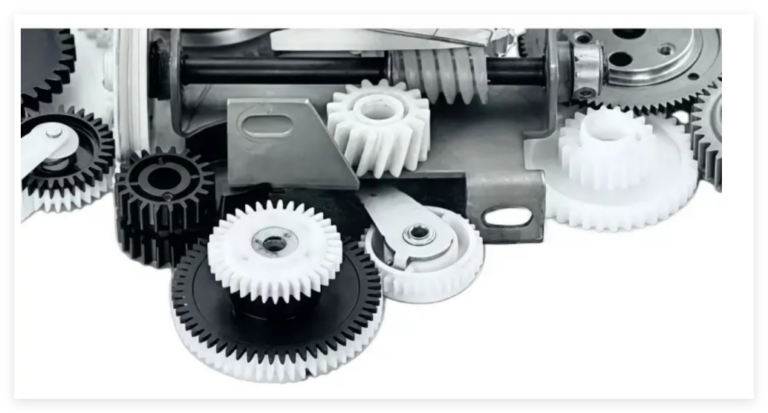

The Injection Mold Explained: Design, Manufacturing, and Fundamentals

In the world of plastic injection molding, the mold—also known as a tool or die—is the core of the entire process. It acts as a precision “negative” of the final part, directly determining the product’s shape, dimensions, and quality. This…

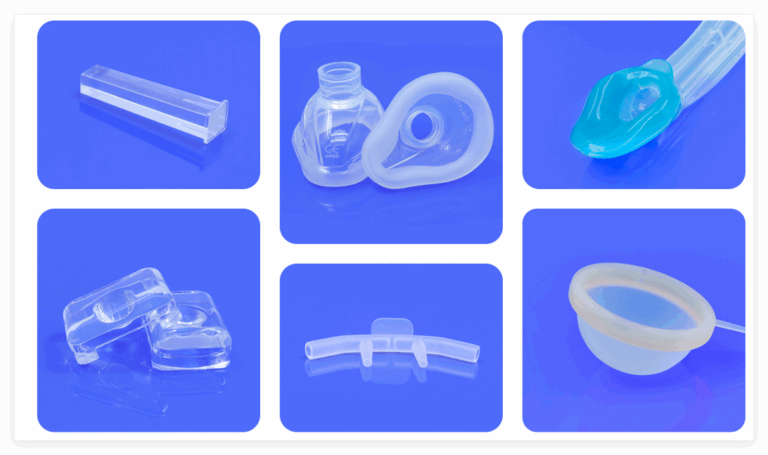

Unifying Function and Form with PC Translucent Components

PC (Polycarbonate) translucent injection molded parts are the secret weapon for achieving this premium, functional aesthetic. They are more than just a component; they are a bridge between utility and emotion. Why PC Translucent Material? More Than Meets the Eye…

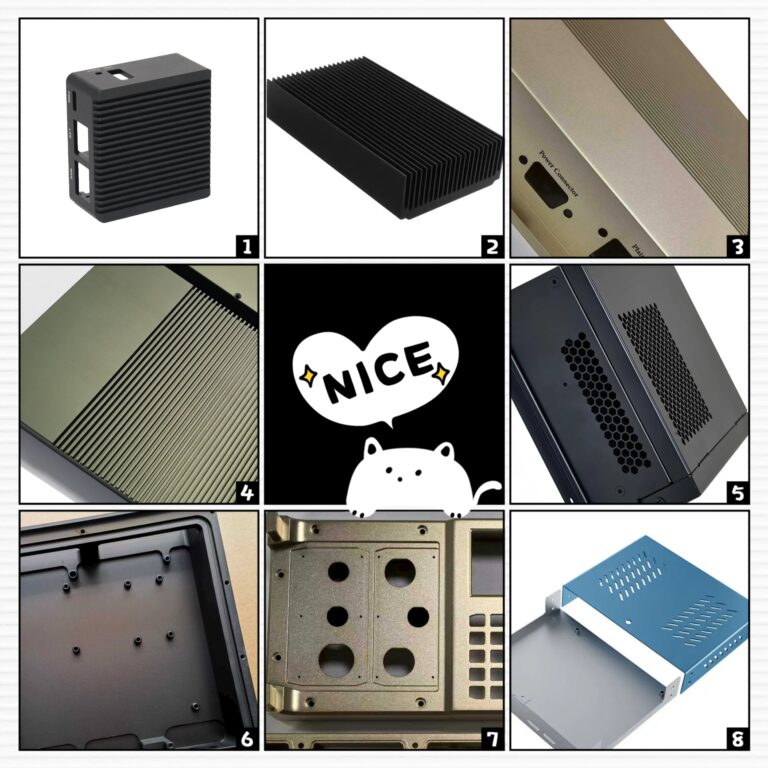

Where Precision Meets Unmatched Durability: CNC-Machined Components with The Power of MIL-A-8625 Type III, Class 2 Hard Coat Anodizing

PANTONE Black6C Anodized Black Dyed per MIL-A8625 Type lll Class 2 This isn’t just a finish; it’s a performance-enhancing armor: ✔ Exceptional Wear Resistance: The hard anodized layer (Type III) provides superior surface hardness, significantly outperforming standard anodizing.✔ Superior Corrosion…

From Concept to Market Hit: How We Created a Product with 200% Exceeding Sales Expectations in 6 Months

Several years ago, a leading hookah brand approached us with an ambitious challenge: to create plastic components with a premium soft-touch finish using a specialized silicone oil spray coating. What unfolded was a story of innovation, close collaboration, and manufacturing…