Capabilities

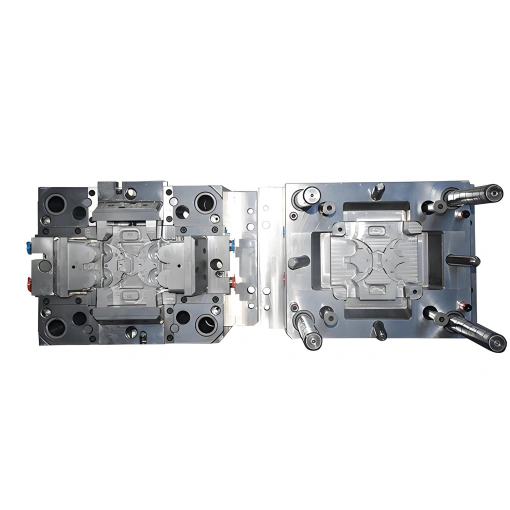

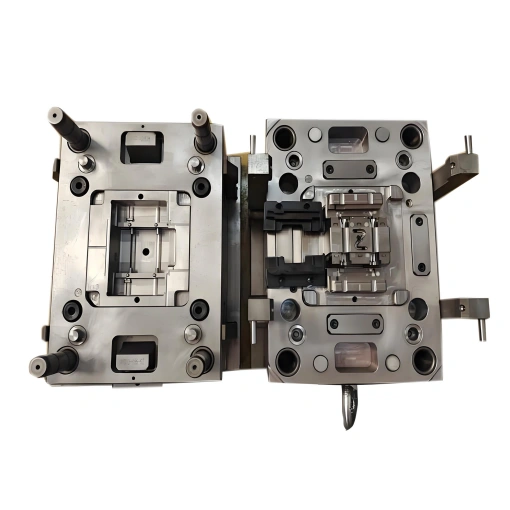

Mold Design and Analysis

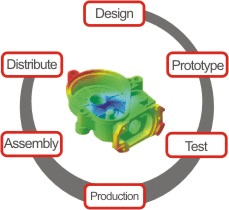

Rilong’s unique, molder-friendly approach distinguishes us from the competition. By combining decades of experience with the latest technologies, we deliver the finest tooling available. Our dedication ensures superior workmanship, comprehensive global program management, and advanced product development techniques. Additionally, we offer the industry’s best product lifecycle management system.

By using a data-driven scientific approach to developing and optimizing the injection molding process, we can provide more consistent processing and parts quality for our clients. The Design for Manufacturability, or DFM helps to eliminate costly re-tooling or delays in the manufacturing process caused by a problem within a part design.

We will collaborate with you to thoroughly understand your product design and performance requirements. We will put all of our capabilities to work to ensure that the finished product is exactly what you want it to be, delivering it promptly and precisely as ordered.

Design For Manufacturability

A helpful tool that Rilong provides makes Injection molded plastic parts just a whole lot easier.

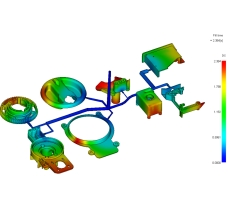

Moldflow Analysis

Part of the Digital Prototyping solution, helps you avoid potential manufacturing defects and get innovative products to market faster.

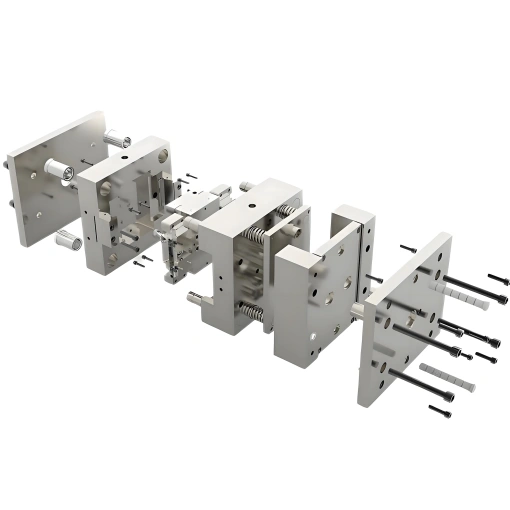

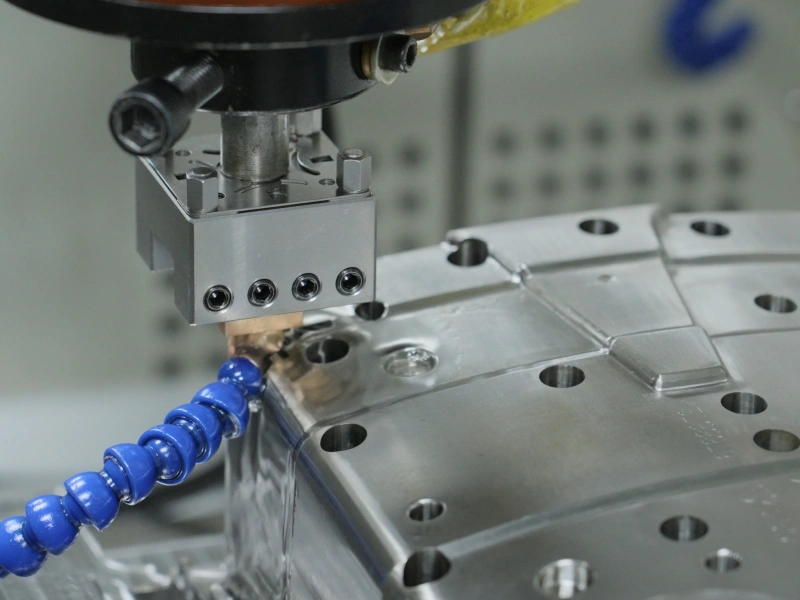

Mold Manufacturing

Manufacturing Problem Solving

Rapid Prototyping

Parts Contract Manufacturing

We provide an extensive array of processing techniques for both metal and plastic components.

Mass Manufacturing

Whether you need advanced injection molding, mold-making, or die-casting processes, Rilong has you covered.

As injection molders, we serve all industries including consumer products, medical, telecommunications, construction, and transportation.

Low-Volume Production

Low-volume manufacturing utilizes rapid prototyping, 3D printing, CNC machining, and vacuum casting services.

Upon obtaining the 3D CAD data file for the manufactured parts, then analyze and apply the most suitable manufacturing technique based on the part demand.

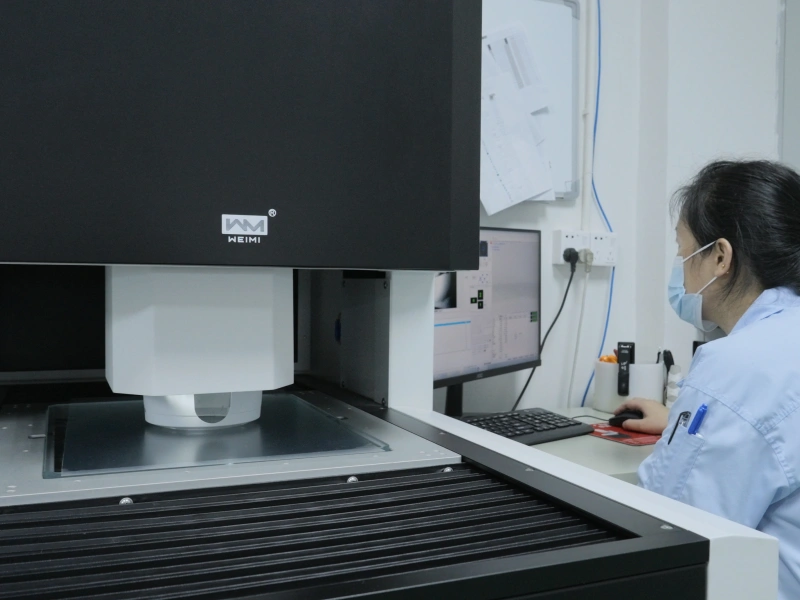

Quality Assurance

Value-Added Secondary Capabilities

Advanced CNC Mold-Making Technology