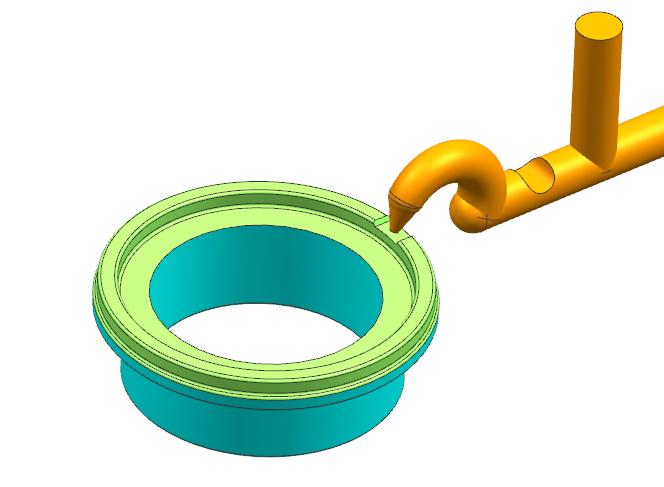

How to optimize mold gate design to avoid plastic part sink marks

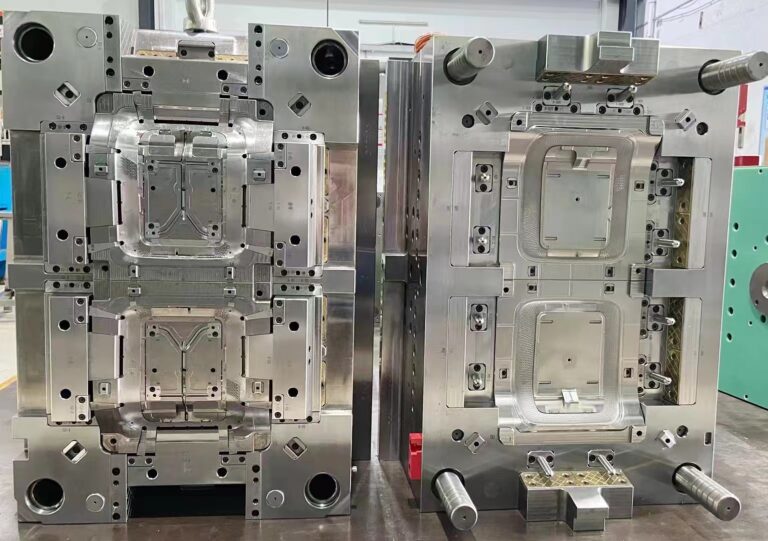

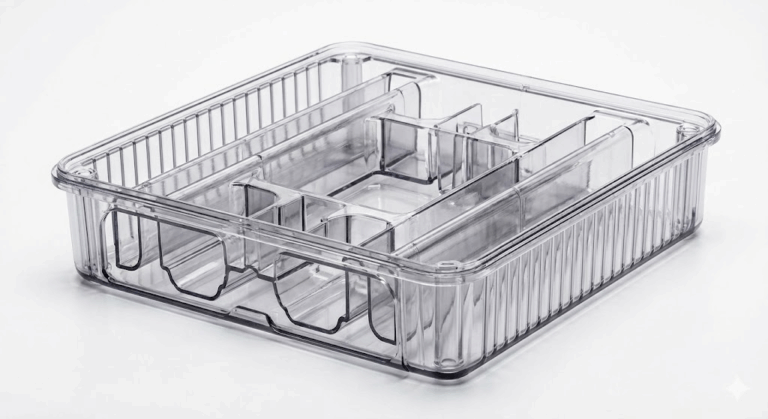

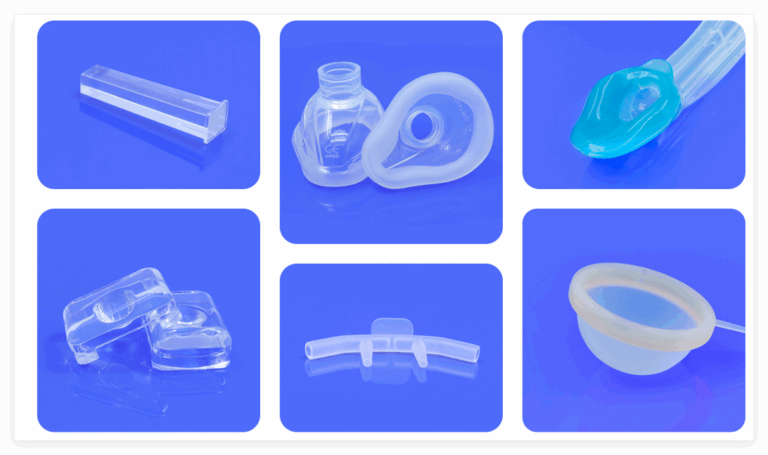

Optimizing Gate Design to Avoid Sink Marks (Dents) in Injection Molding The core principle behind optimizing gate design to prevent sink marks is to ensure that the molten material can effectively pack out the thick-walled areas during the holding pressure…