Need to turn your concept into reality?

Submit your concepts, prototypes, or CAD files, and we’ll handle the rest—design refinement, prototyping, and final production. With extensive experience in diverse projects, we ensure solutions tailored to your unique requirements. 80% of our clients come through referrals—proof of our reliability and expertise.

Contact Us to Discuss Your Next Project!

- Concept Phase

In 2014, we received a new project that required us to provide design and manufacture for a custom mobile phone case.

1. Begin with their design concepts and sample pictures:

Before we initiate the design of the mobile phone, here are the details of our discussion.

A. The front panel’s location should be as indicated in the diagram.

B. The front panel’s surface treatment (referencing the red mobile phone): the surface requires painting, while the frame should be chrome-plated.

2. Backplate, SIM, and battery holder (Middle section)

The external dimensions (L x W x H) should match those of the Nokia mobile phone sample (refer to the attached image “silver middle part”), but the thickness is subject to our engineers’ recommendations based on design requirements. The appearance and structure should remain consistent with the red mobile phone sample (refer to the attached image “red middle part”).

A query from our engineering team: We have observed that the red mobile phone features dual SIM slots. Is it necessary to include dual SIM functionality in the new mobile phone design?

3. Battery cover (Back section)

The width should be consistent with the mobile phone sample (refer to the attached image “silver back part”), while the length should be redesigned concerning the red battery sample. The thickness is subject to our engineers’ recommendations based on design requirements. The appearance and structure should remain consistent with the red mobile phone sample (refer to the attached image “red battery part”).

4. Front Window

The dimensions should be tailored to the customer’s display screen sample.

5. P+R keypad

The dimensions and structure can be based on the image labeled “5 keypad dimension”; the keypad’s surface finish and tactile feel should match the image labeled “5 red keypad”; all markings on the keypad will be in Arabic, with the artwork file to be provided by the customer.

Note: If the markings require backlight illumination, the surface finish should be spray painting, laser etching, and UV coating; if backlight illumination is not required, the surface finish should be silk printing and UV coating.

Call us Now for your project success!

- Design& Engineering Phase after confirming the design concepts

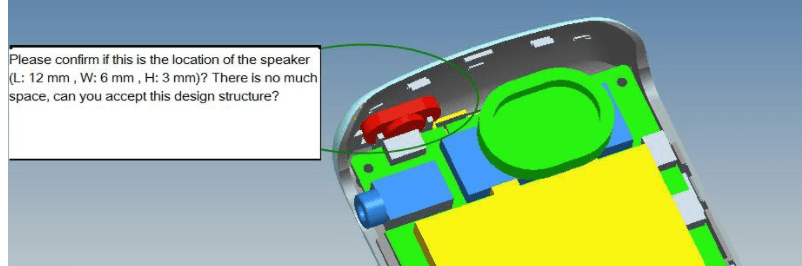

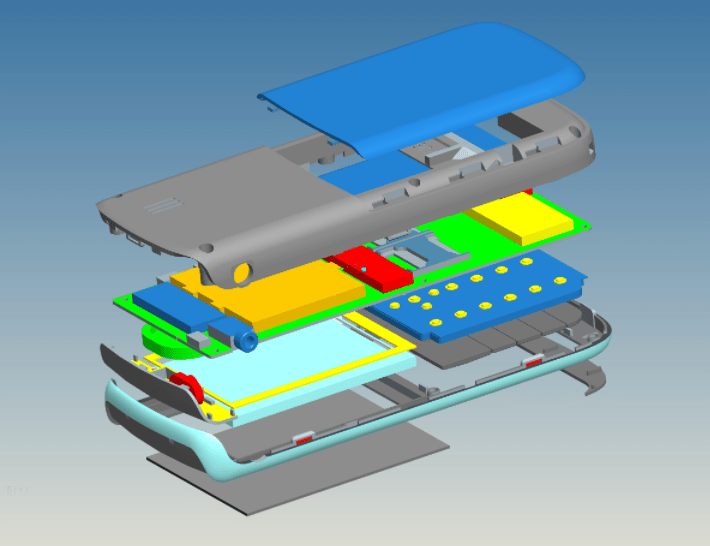

- Our designers employ 3D modeling software to craft a meticulous three-dimensional representation of the smartphone, encompassing the casing, window, keypads, and internal electronic components.

- Screenshot of the 3D model

Screenshot of the 3D model

Screenshot of the 3D model

Full-service partner for your product development!

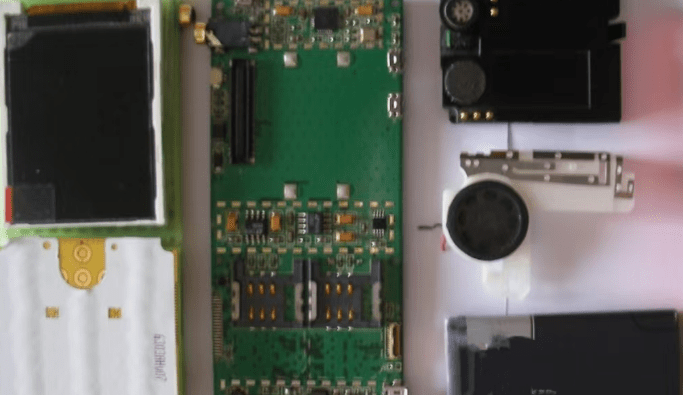

- Make prototypes to verify the design:

Creating prototypes and subjecting them to rigorous testing are fundamental to agile product development. This process allows for the timely identification of problem areas, enabling immediate implementation of changes. We deliver rapid, high-quality prototypes using advanced techniques such as CNC machining, 3D printing, vacuum casting, and mold-making.

Prototypes of the cell phone casing.

Feel free to ask us to get Total Manufacturing Solutions!

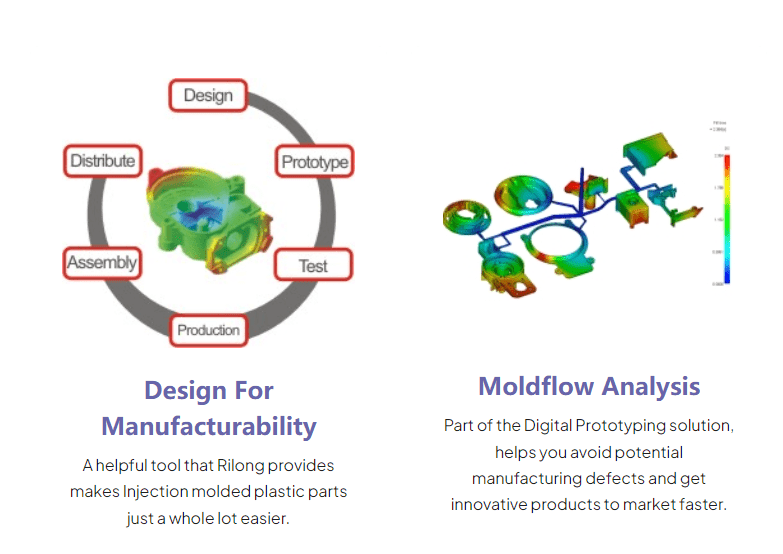

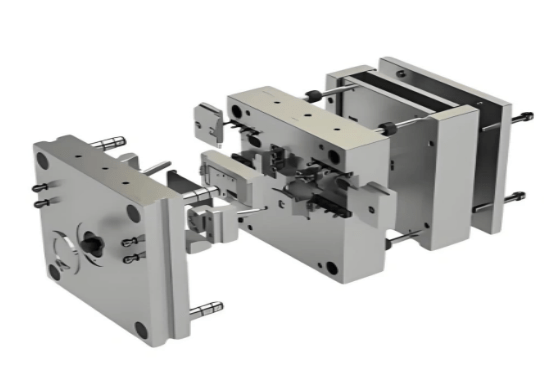

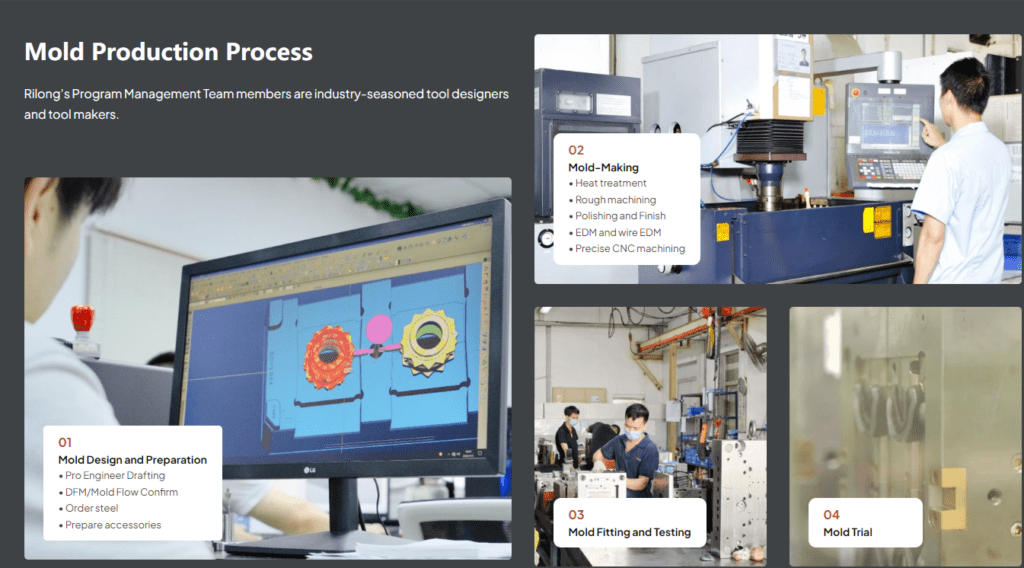

Mold Design for Manufacturability (DFM) and Tool Production

In testing the prototypes, we optimized the design and finalized it to enhance manufacturability, leveraging Mold DFM (design for manufacturability) and mold flow analysis.

In our mold production center, we have a variety of imported high-precision CNC machining, spark machines, wire cutting equipment, precision grinders, and other processing equipment, which are imported from Japan FUNAC, Japan Sodick, Swiss CHARMILLES, Swiss AGIE etc. to make sure the high precision mold request.

Contact our mold designing and engineering team to start your innovation!

Embark on series production

Upon customer approval of the samples, we initiate series production adhering to the agreed quality inspection standards and the gold samples.

We have the Most Professional Production team, using a Scientific and Rigorous System Management Model to arrange the Production Plan and Shorten the Production Delivery Time.

. Quality Inspection and Standards

During the mold fabrication, sampling, and production stages, we conduct rigorous inspections using advanced testing equipment, including a Sodick CMM, video measuring system, mesh tester, and color difference instrument.

Contact us and ask for more details!