One, Achieving Color Matching Using Standard Color Chips

In the production process, companies can use standard color chips to match the color of plastic parts. Standard color chips are a tool that includes samples of various commonly used colors. By comparing the color chips with the plastic parts to be produced, the exact color needed can be accurately determined.

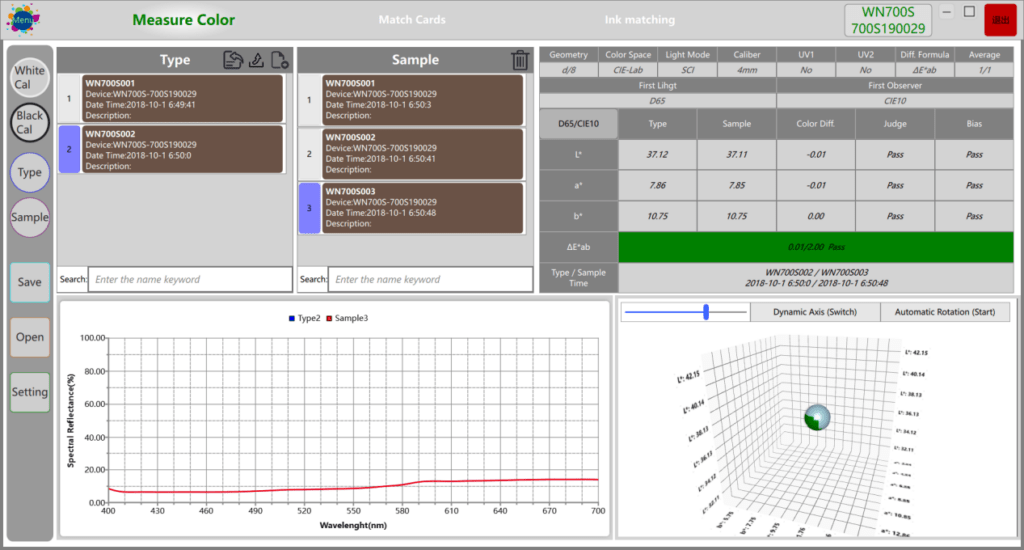

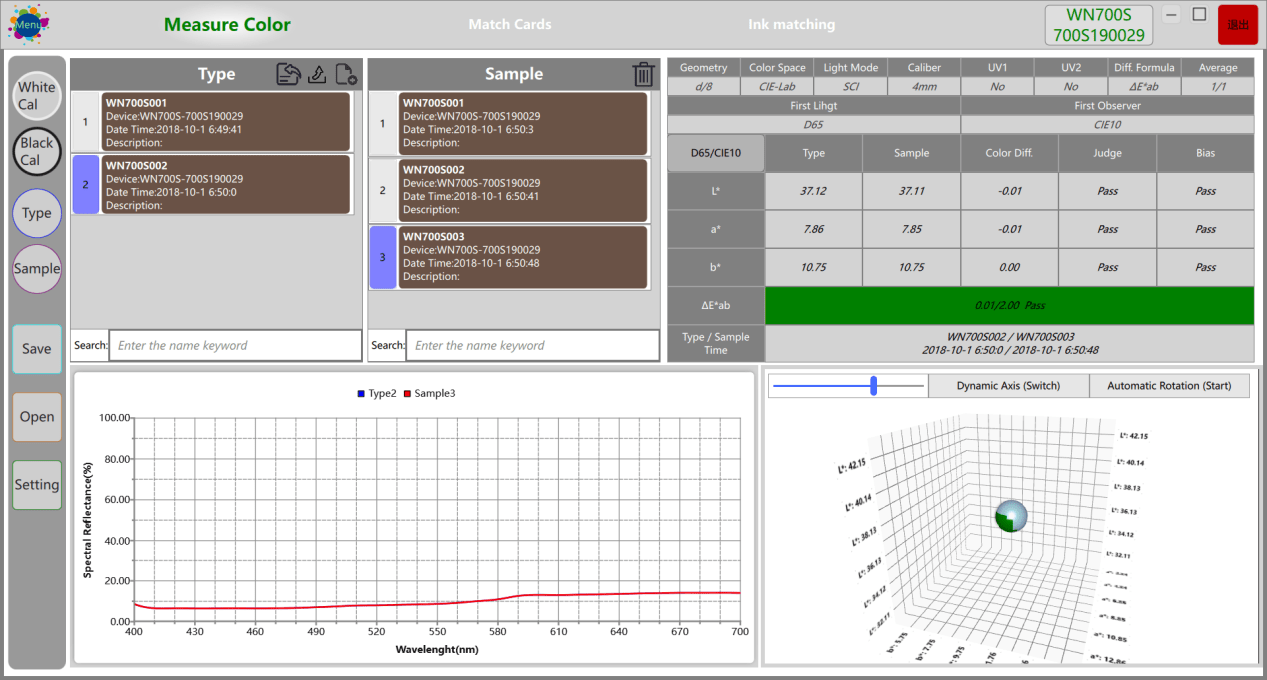

Two, Color Inspection Using Color Difference Meter

A color difference meter is a tool for measuring color differences. It can compare the color of the plastic parts produced with the standard color and thus achieve color inspection and judgment. Using a color difference meter can help companies detect color deviations in the production process and effectively control product quality.

Three, Measuring Light Color with a Colorimeter

The surface gloss and color of plastic parts are related to the product’s appearance quality and process. To ensure the stability of plastic part colors, companies can use a colorimeter to measure light color. A colorimeter can measure the changes in gloss at different angles and determine whether there are problems of uneven gloss and color deviation.

Four, Controlling the Proportion of Plastic Raw Material Additives

The standard color of plastics is determined by the international Pantone color card, and the formula for plastic pigments is determined by the concentration ratio of the pigments. In the production process of plastic raw materials, the proportion of pigment additives and the concentration of pigments need to be precisely controlled to ensure that the products produced meet the color requirements.

Five, Controlling Processing Technology and Temperature

During the production process of plastic parts, processing technology and temperature are key factors that need to be precisely controlled, especially for special colors such as metallic luster colors or pearl colors. At this time, precise adjustments and control need to be made based on the color requirements of the product to ensure that the color deviation does not exceed the standard range.

Six, Summary

The precise management of plastic part colors is very important. Companies should use standard color chips, color difference meters, and colorimeters to achieve color matching and inspection, and pay attention to the influence of raw material additive proportion, processing technology, and temperature on color control to improve product quality .