Have you ever faced a design challenge where plastic parts fell short? Maybe they cracked under pressure, lacked grip, or failed to seal properly?

You’re not alone. Many engineers and designers start with plastic for its versatility and cost-effectiveness—but soon discover that certain applications demand more: more flexibility, more durability, more resistance to extreme conditions.

That’s where custom rubber parts come in.

While our legacy has been built on precision plastic components, we’ve expanded our expertise to include high-performance rubber manufacturing since year 2006—solving problems that plastic alone cannot:

🔹 Where Plastic is Brittle → Rubber is Flexible

Rubber parts absorb shock and vibration, making them ideal for protective seals, dampers, and grips.

🔹 Where Plastic Slips → Rubber Grips

Superior traction makes rubber perfect for buttons, handles, feet, and anti-slip surfaces.

🔹 Where Plastic Leaks → Rubber Seals

From IP-rated enclosures to fluid systems, rubber provides reliable sealing even under compression or temperature shifts.

🔹 Where Plastic Degrades → Rubber Endures

Silicone, EPDM, Nitrile, and other rubbers resist UV, ozone, chemicals, and extreme temperatures (–60°C to 300°C).

But Here’s the Best Part: You Don’t Have to Choose.

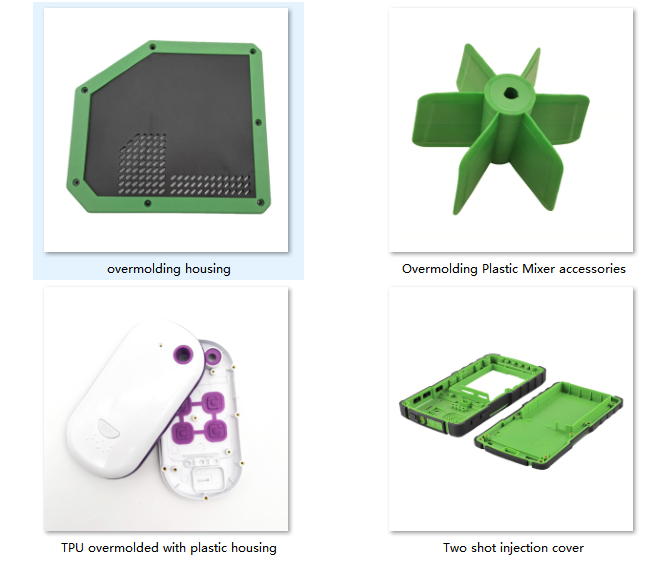

Many of our most successful projects combine plastic structural components with rubber functional elements—overmolded grips, integrated seals, tactile buttons—all under one roof.

We offer end-to-end support:

- 🛠️ Design for Manufacturing (DFM) for both plastic and rubber

- 📦 Tooling, prototyping, and production

- ✅ Material selection guidance—so you never over-engineer or under-specify

Ready to Explore Whether Rubber Is Right for Your Application?

We help innovators navigate the transition from plastic to rubber—or find the perfect hybrid solution.

👉 Learn more about our expanded rubber manufacturing capabilities on our website:

www.rilongsilicone.com