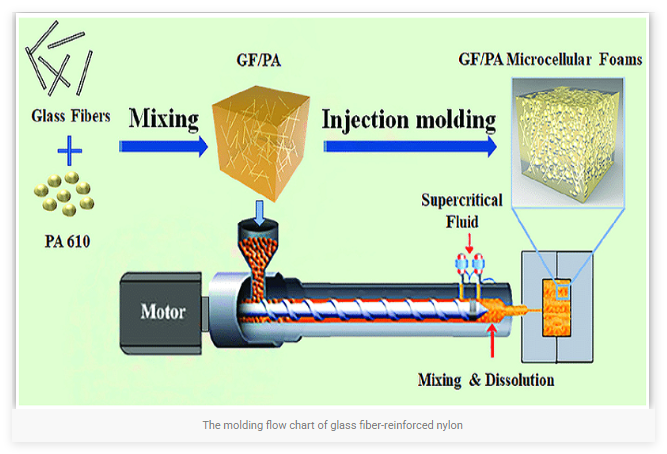

In the field of engineering plastics, nylon 66 (PA66) with 30% glass fiber (GF) is a widely used high-performance material known for its excellent mechanical strength, heat resistance, and dimensional stability. However, due to its high wear characteristics, mold design and injection molding processes require special attention.

Characteristics and Challenges of PA66 + 30% GF Material

The main advantages of PA66+30GF include:

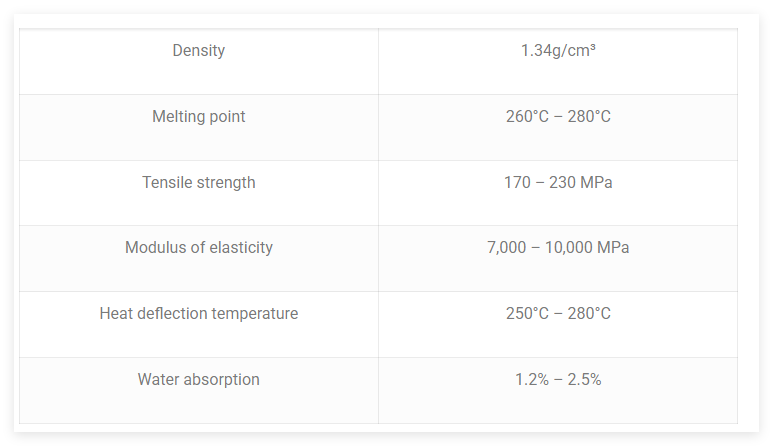

High Strength & Rigidity: Glass fiber reinforcement significantly increases tensile and bending strength.

Heat Resistance: Short-term temperature tolerance up to 250°C, long-term usage temperature between 150-160°C.

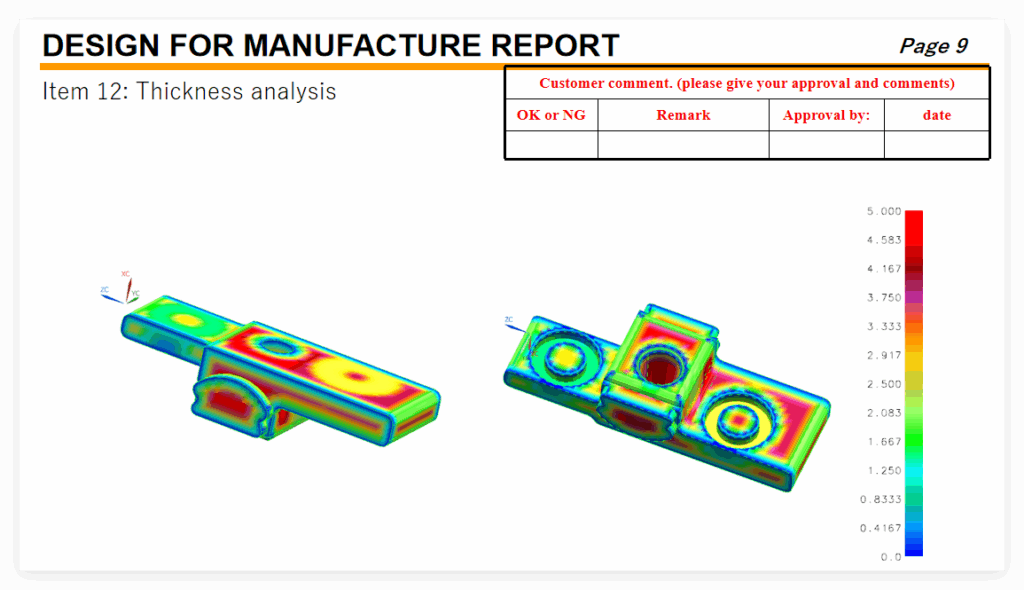

Dimensional Stability: Glass fiber reduces shrinkage and minimizes deformation risk.

However, this material also presents some challenges:

High Wearability: Glass fiber accelerates mold wear, causing issues such as surface roughening and flash.

Reduced Fluidity: The presence of 30% GF decreases melt fluidity, affecting filling efficiency.

Mold Corrosion: PA66 itself has acidic properties, and glass fiber further exacerbates mold corrosion.

The following brands of nylon and glass-filled nylon materials we worked are:

Zytel®PA66 70G30HSLR

Ultramid® PA66 A3EG6

Amilan™PA66 CM3004G-30

Ascend Vydyne® R530H

DSM-K-FKGS6_B PA6-GF30 FR(17)

The table below displays the performance characteristics of glass-filled polyamide composites (Nylon 66 with 30% glass fibers).

Key Points in Mold Design for High-Wear Materials

(1) Selection of Mold Steel

Corrosion Resistance & High Hardness: Recommended mold steels include 2316, 420,2083, SKD61 for corrosion resistance.

Heat Treatment Requirements: A hardness of HRC 52+ can reduce wear, but long-term use still requires optimized surface treatment (such as chrome plating or nitriding).

(2) Optimization of Runner and Gate Design

Avoid Sharp Corners: Reduce glass fiber erosion on the mold.

Multiple Gates: Minimize warpage caused by fiber orientation (using three gates can reduce warpage by 56%).

(3) Reinforcement of Ejection System

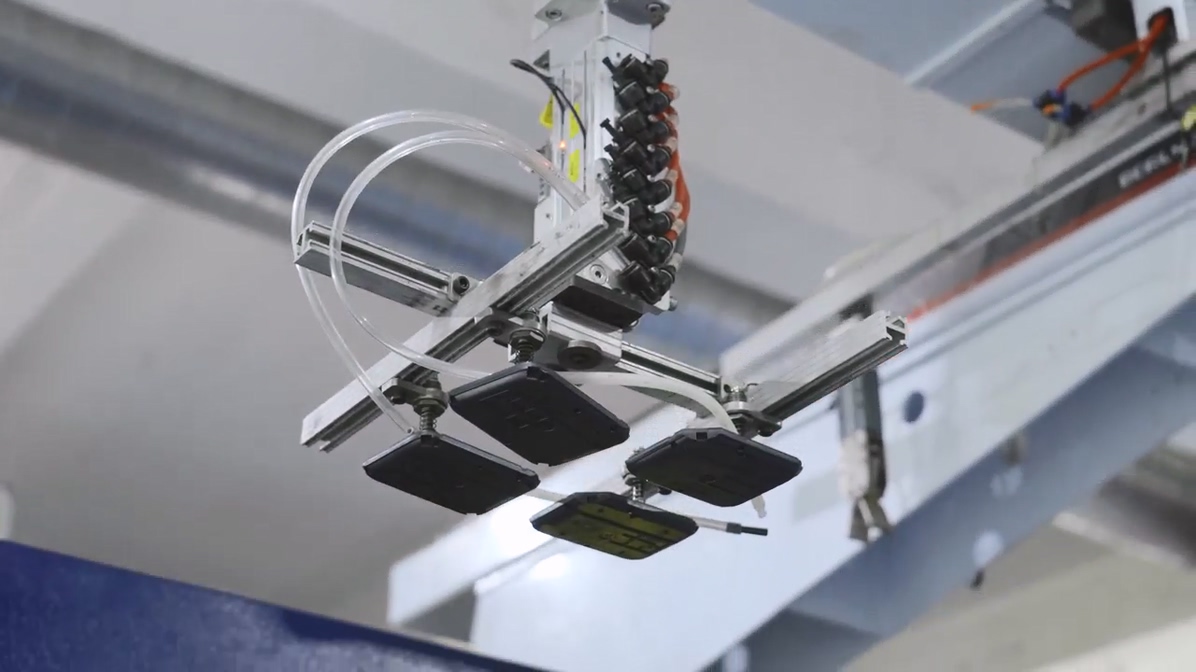

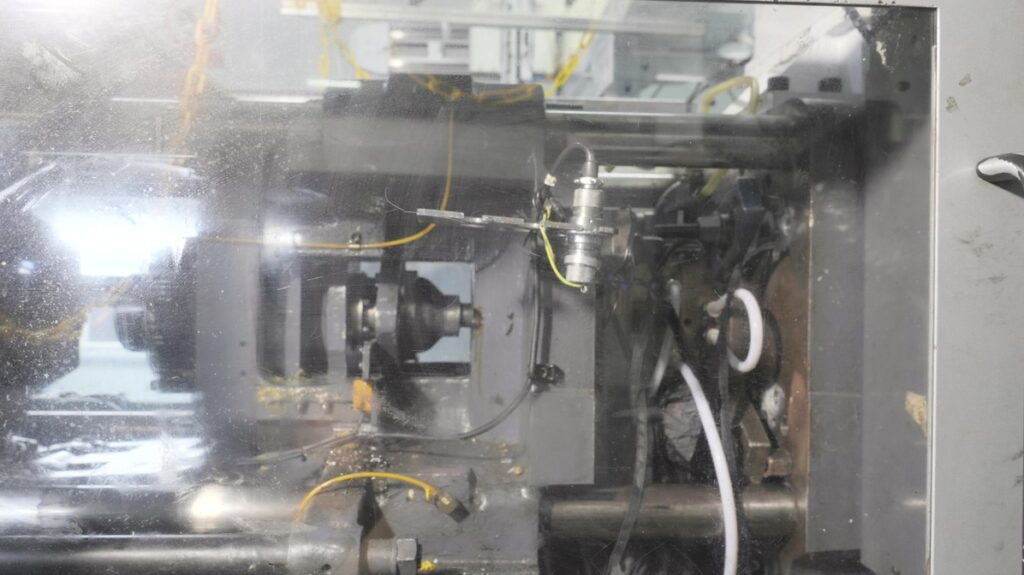

Due to the high demolding force of PA66+30GF, more ejector pins or hydraulic ejection systems should be used.

3. Optimization of Injection Molding Process

Melt Temperature: 280-300°C to ensure proper dispersion of glass fibers.

Mold Temperature: 80-120°C to reduce internal stress.

Hold Pressure: Increase appropriately to minimize shrinkage, but too high may cause flash.

4. Special Considerations for Long Glass Fiber Reinforced Materials (LFT)

Long glass fibers (>5mm) provide higher impact strength but have lower fluidity, requiring careful mold design:

Prevent Fiber Breakage: Use low-shear runner designs.

Mold Surface Polishing: Reduce fiber abrasion on the cavity.