Plastic Injection Molding

Turning Design into Mass Production

Whether it is a design, development, or manufacturing problem, we can engineer a solution that solves it.

Premium Plastic Injection Molding of Exquisite Quality

Plastic Injection Molding Materials

The general materials listed below are for custom plastic injection molding.

Different Types of Molds to Meet Customer Needs

| Core Advantage | CNC machining and compression&injection molding |

| Product Material | ABS, PC, PA6, PA66, PC+ABS, POM, PA6+10GF, Nylon, PE, PVC, PE, PVC, TPE, TPU, TPV, PET, PEI, LCP, PS, POM, ASA, HDPE, PEEK, PPS, |

| Product Finishing | Silkscreen, Hand oil coating, Laser etching, Spraying, Glossy coating, Matte Coating, UV Painting, Pad printing, Chrome Plating, Nickle Plating, Non-conductive, Vacuum Metallization, EMV coating, etc. |

| Mold Standard | DME, HASCO,China domestic |

| Runner System | Hot runner and cold runner, YUDO hot runner |

| Mold Lifecycle | 50k-1000k shots |

| Mould Finishing | Normal Polishing (SPI B1-B3), High Polishing (SPI A1-A3), VDI Texturing, YS1281 Texturing, EDM, Sandblasting Grinding |

| Inquiry Information | 2D:dwg,dxf,edrw 3D:step,lgs,X-T,Prt,Sldprt Physical Samples or the size of the multi-angle pictures |

| Advanced Tool Equipment | ◆ 8 Advanced CNC machines: Charmilles, Seiki, MITSUBISHI ◆ 4 Advanced EDM: CHARMILLES, SODICK ◆ 2 Advanced WEDM: CHARMILLES, SODICK |

| Inspection Standard | FAI (First Article Inspection), Dimension Report, Outgoing products inspection report |

Transforming Your Ideas Into a Reality

Concept to distribution, We get it done

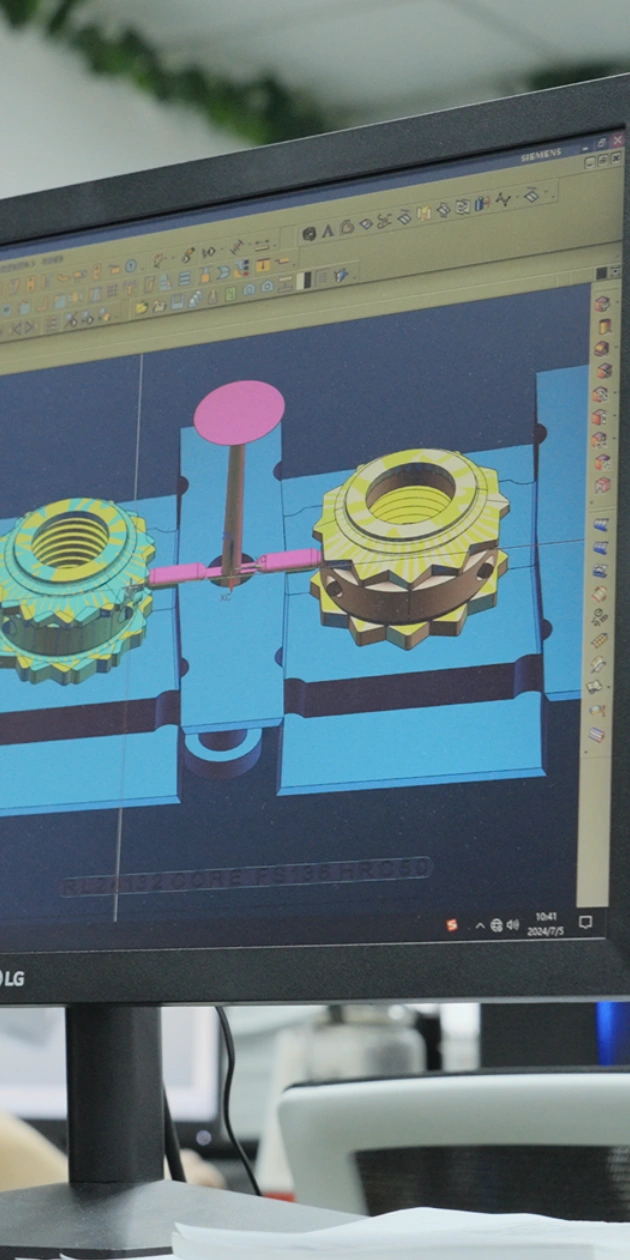

DESIGN

From initial sketches to detailed CAD/CAM designs, our team of skilled technical designers and engineers will expertly guide you in preparing your component for the molding process.

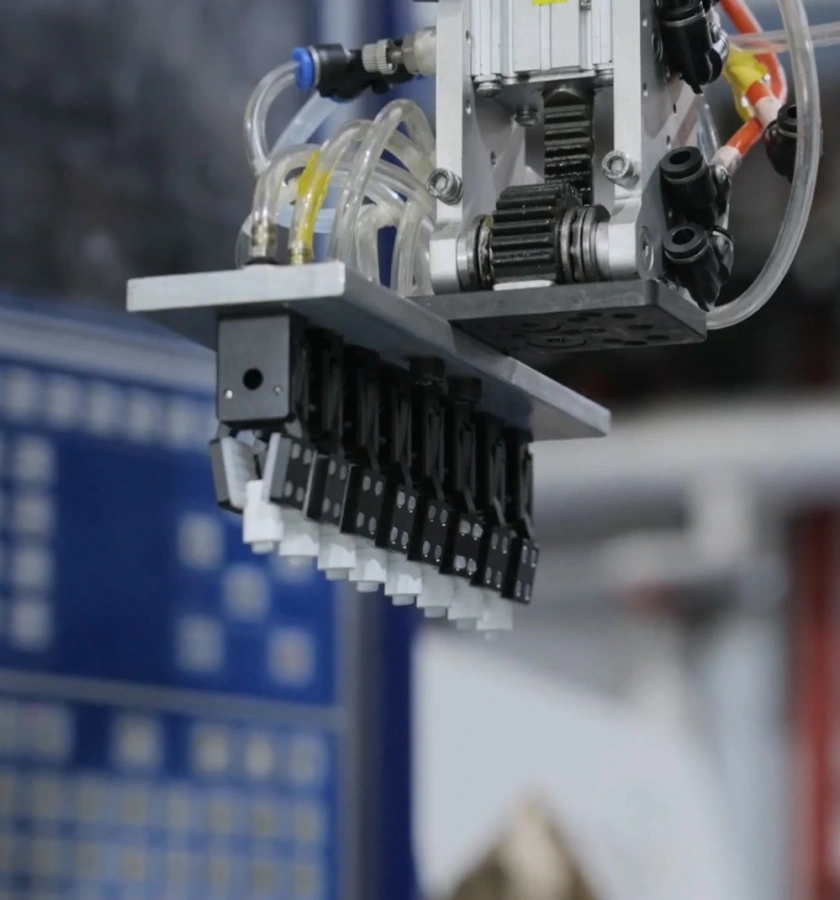

MANUFACTURING

Our multiple facilities, equipped with the latest technology and staffed by experienced professionals, ensure that we meet a wide range of production needs with precision and efficiency.

FULFILLMENT

Rilong offers global distribution services through our three strategically located warehouses in Shenzhen, Dongguan, and Zhuhai. This ensures timely delivery, regardless of your location.

Customer-Focused Partnership

At Rilong, we design and develop new product molds based primarily on our customers’ ideas. We take pride in listening to customer feedback and implementing their innovations, ensuring that their vision is brought to life.

Leaders in Innovation

Rilong Precision Mold supports this rapid pace by developing and building advanced tools that ensure we remain at the forefront of the industry, consistently leading with innovation and excellence.