Want a custom configuration?

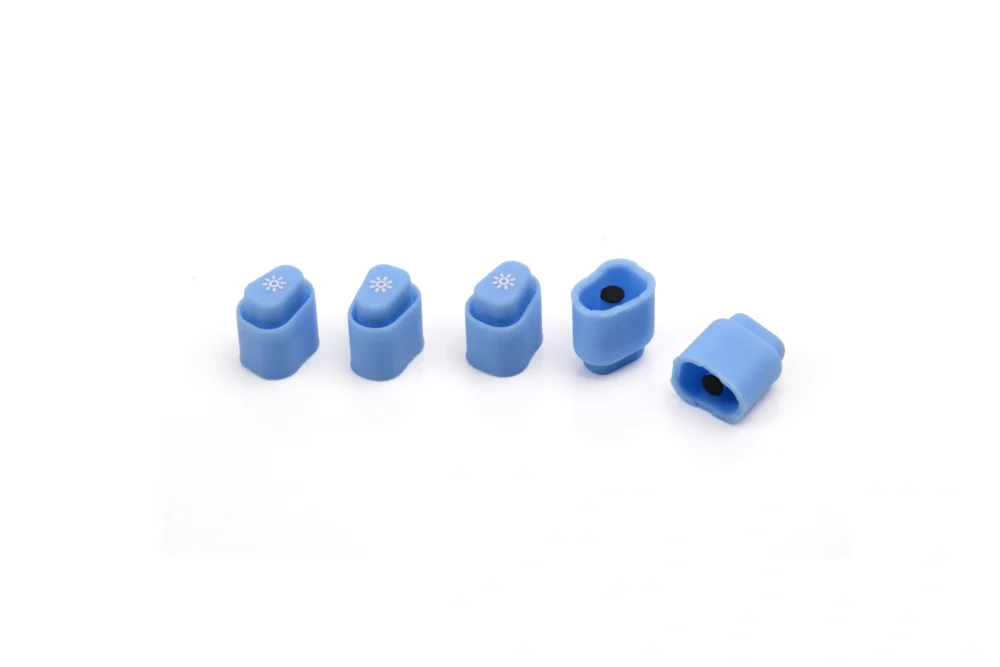

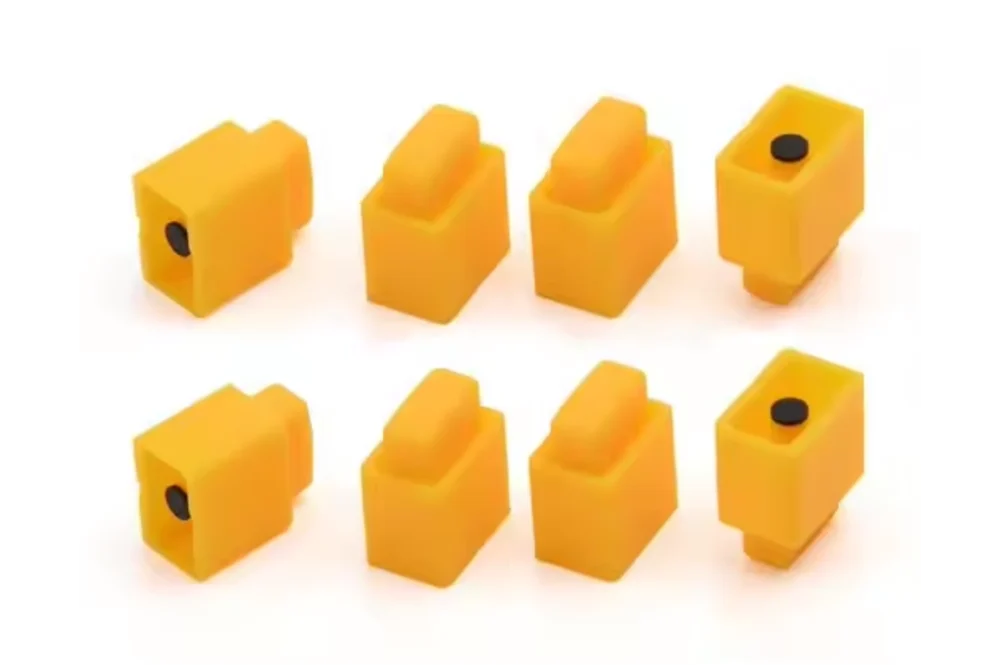

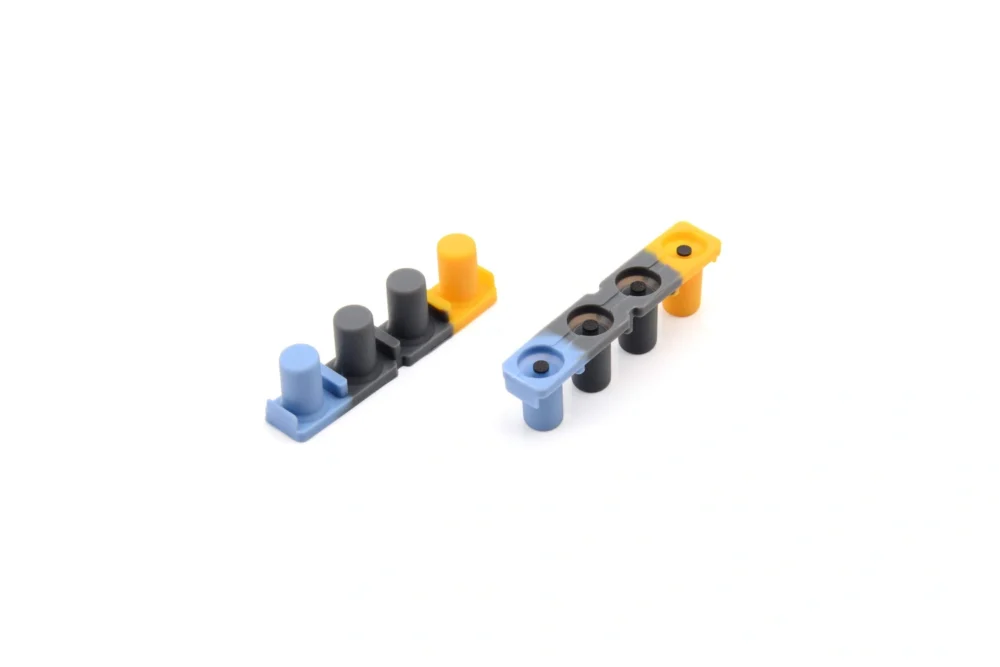

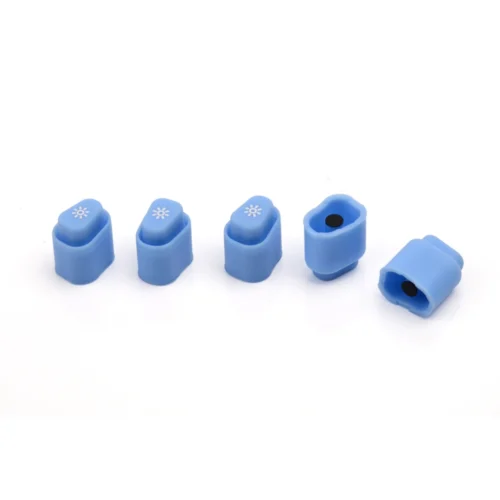

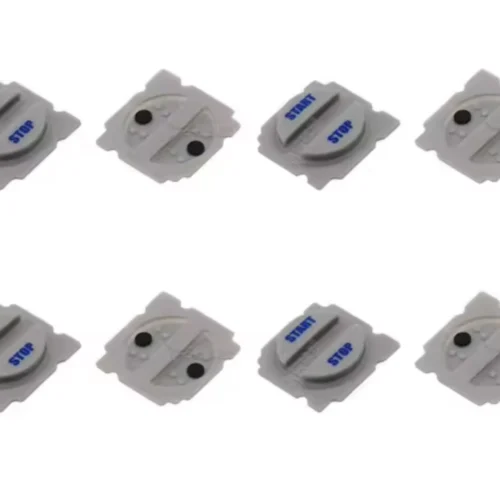

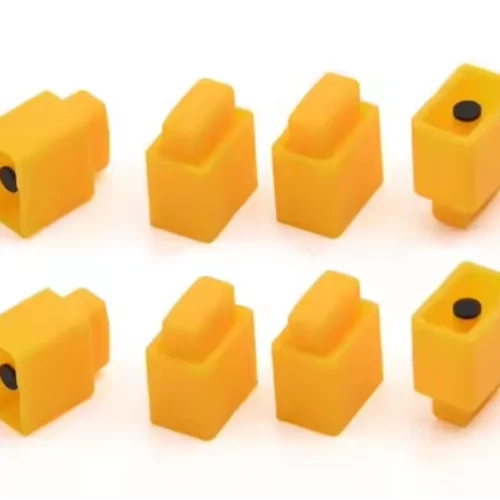

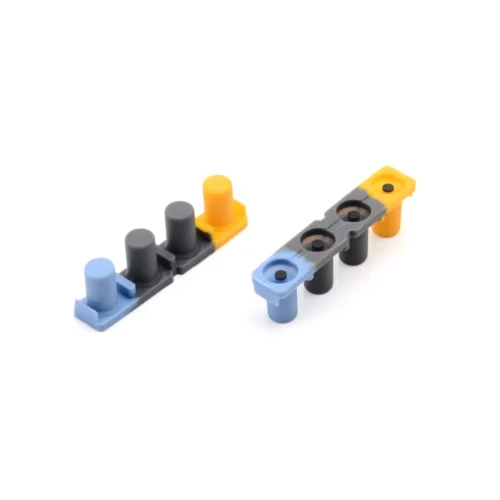

Custom UV Resistant Silicone Keypads Touch Sensitive Silicone Keypads for Medical Device

$0.10

Customize OEM rubber parts for electronic, home alarm system, medical, and automotive products with different colors and materials such as silicone, NBR, NR, SR and EPDM, P+R, silicone+metal dome/Polydome/circuit are available in RiLong. We have done many kinds of silicone keypads with conductive pills/ silk printing/pad printing/ spraying/ matt coating/ laser etching/drop coating/ epoxy per customer’s various designs and specifications.

Key attributes

| Shaping Mode | Rubber Mould |

| Place of Origin | Guangdong China |

| Brand Name | Rilong |

| Model Number | OEM/ODM |

| Product Material | Silicone Rubber |

| Product | Household Product |

| Keyword | Silicone Rubber Molding Service and OEM Assembly |

| Mold Base | LKM, HASCO, DME, or upon the customer’s requirement |

| Mold Life | 50,000 to 1,000,000 shots |

| Mold Core | 45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc |

| Production Material | Silicone, Natural Rubber, NBR, NR, EPDM etc. |

| Mold Cavity | Single or Multiple Cavities |

| Packaging | Polybag packing or packed according to customer requirement |

| Transportation | By sea or by air as customer requirement |

| Main Export Country | USA, UK, Germany, Switzerland, France, Italy, Australia and Southeast Asia |

Lead time

| Quantity (units) | 1 – 1000 | 1001 – 5000 | 5001 – 10000 | > 10000 |

| Lead time (days) | 15 | 20 | 30 | To be negotiated |

Customization

| Customized logo | Customized packaging | Graphic customization |

| Min. order: 1 | Min. order: 1 | Min. order: 1 |

Need High Quality Injection Molded Parts?

If you have a great idea, we can help bring it to life. We’ve done this before and enjoy becoming partners throughout product creation. From advising you through the mold sourcing process to delivering your new product to customers, we want to work with you every step of the way.

A Never-Ending Pursuit to Get Better

Our strength is our flexibility and adaptability. We combine our experience with your ideas to bring out products that are one step into the future.

Quality Defect-Free Production

Our vision is to not only deliver products that exceed customer expectations but also to help them reduce costs by working with them in the mold design fields.

On-Time Order Delivery

We desire to ensure that customers receive the goods accurately and complete delivery in the shortest possible time.