Several years ago, a hookah brand approached us with an ambitious request: to develop plastic components with a premium soft-touch finish (silicone oil spray coating). What followed was a journey of innovation, collaboration, and manufacturing excellence.

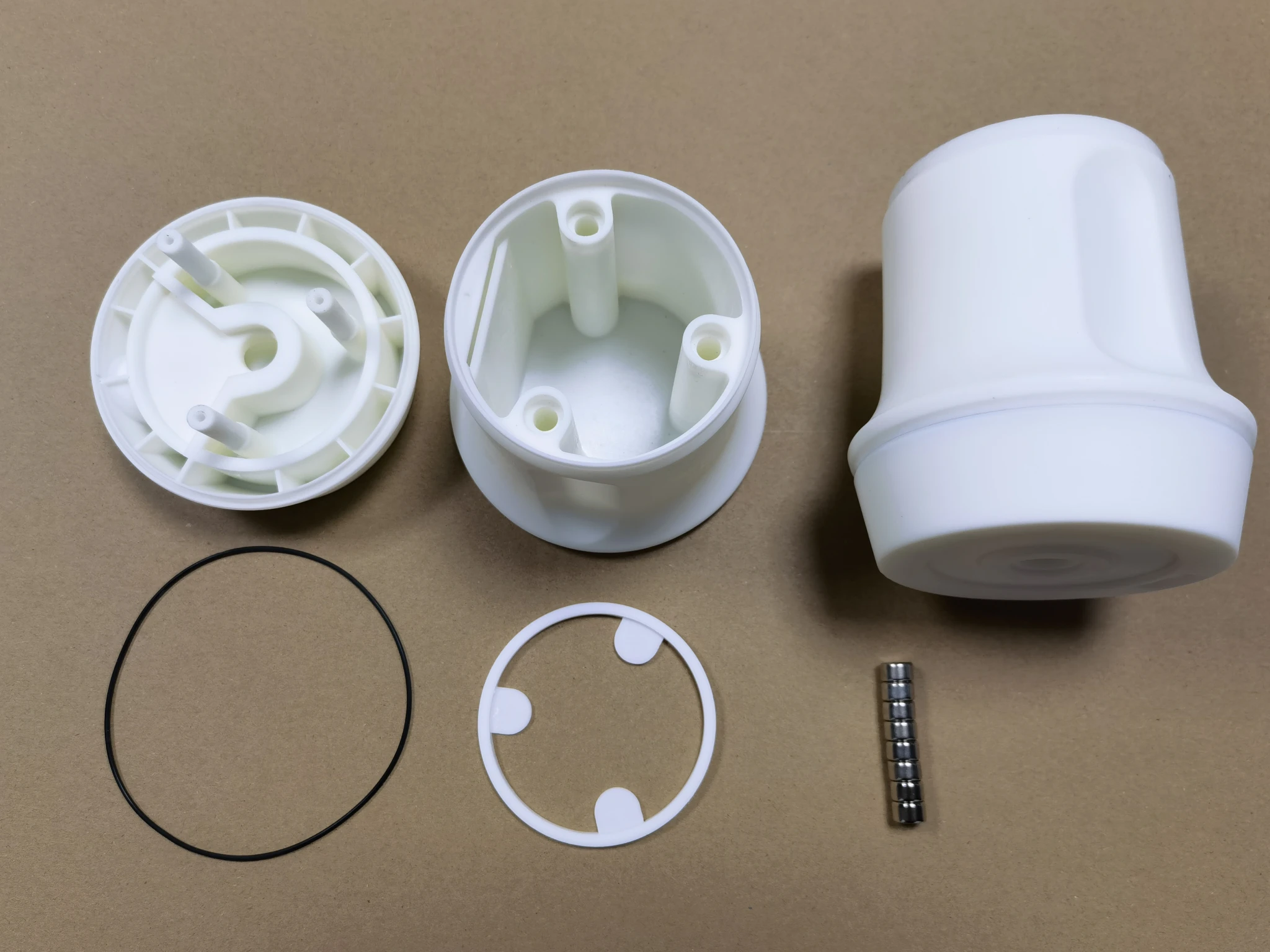

Original Prototype

▎ Overcoming Challenges

• Initial designs had thick walls and heavy metal inserts—unsuitable for injection molding

• Proposed 12+ DFM (Design for Manufacturing) improvements, reducing weight by 35% without compromising durability

• Delivered 5 CNC prototype iterations in 3 weeks to validate design changes

▎ Key Processes & Expertise

✔ Metal insert overmolding

✔ Soft-over-hard two-shot molding

✔ Integrated screw & snap-fit assembly

✔ Primer + silicone oil spray coating

✔ Silk-screen logo printing

Oil spraying

▎ Results & Impact

▶ Full-cycle development in just 6 months (design → mass production)

▶ Exceeded client’s sales expectations by 200% in Q1

▶ Expanded partnership to include end-to-end production (tooling → assembly → packaging)

Assembly Line

This project proves that great products are born when engineering expertise meets creative vision. We specialize in:

• High-performance plastic components

• Premium surface finishing solutions

• Turnkey product development for consumer goods

Interested in transforming your product idea into reality? Let’s connect! #ProductDesign #InjectionMolding #SupplyChain