How to choose an economical production molding plan for the design verification stage?

- CNC prototype is suitable for projects with material requirements, we can choose more materials, such as ABS, PC, PEEK, etc., and the processing accuracy is relatively high, but the processing of complex structures such as angles and lines is not so good. The price is medium. The delivery time depends on the size and structure of the product, if it is simple, we can make it within 7 working days.

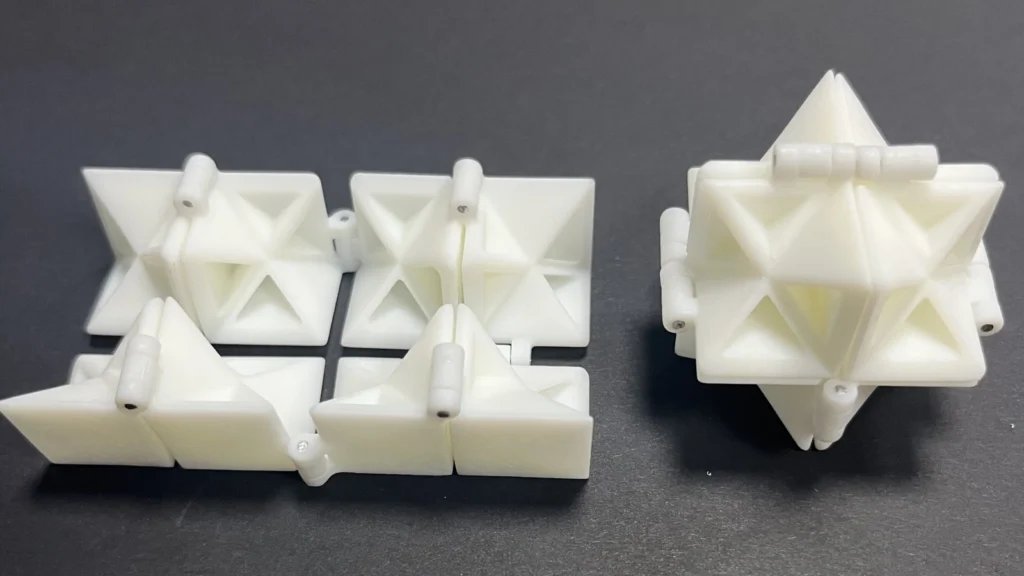

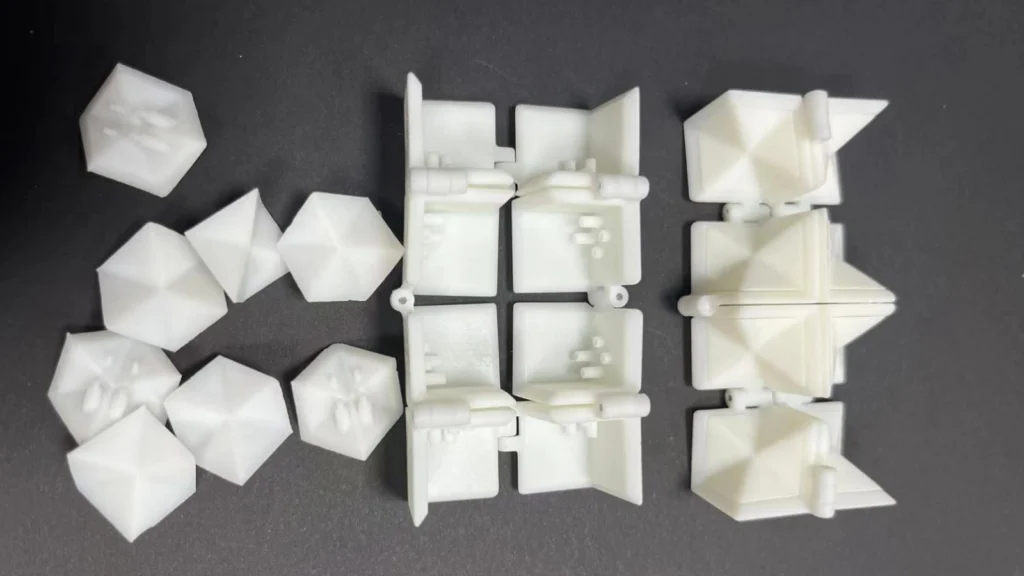

- 3D printing is suitable for complex modeling, such as curves, hollow structures, etc. However, there are limitations on the material and the accuracy is relatively low. The price is low, the lead time will be 3 working days if it is a simple part.

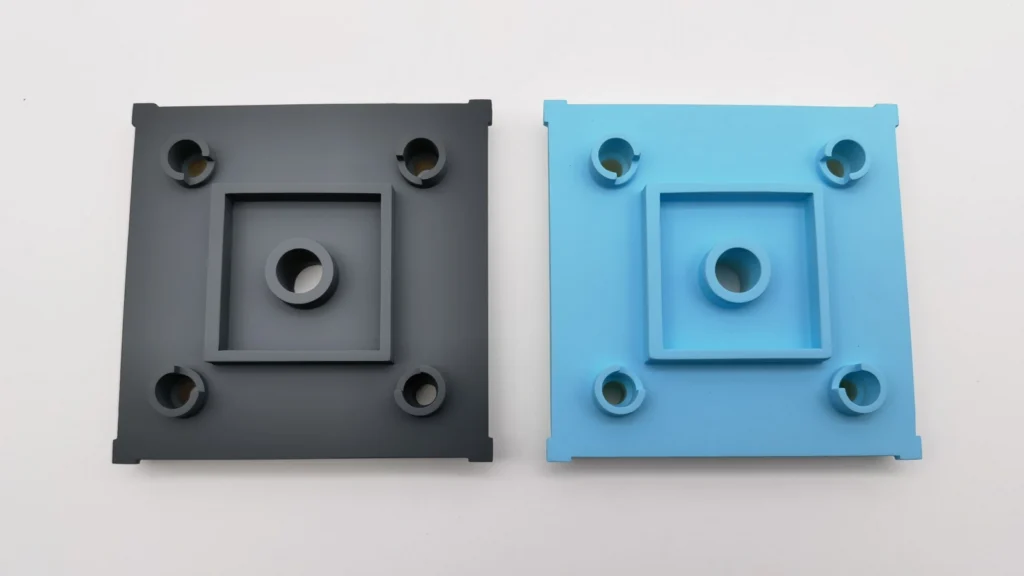

- Vacuum casting, we also called silicone soft mold. Under vacuum conditions, the vacuum silicone mold is made by using the product prototype, and then materials such as PU, transparent PU, POM, ABS, etc are molded into a vacuum mold to produce a replica that is the same as the product prototype. It can achieve the strength and hardness of ABS and other materials, and can also be made with colors required by customers, to clone the same copy of the product prototype. This type of prototyping can only produce dozens of samples, if beyond the quantity, the tolerance cannot be guaranteed. It’s a more common processing method, the price will be more expensive than the first two processes, and the lead time will also be longer, depending on the structure.