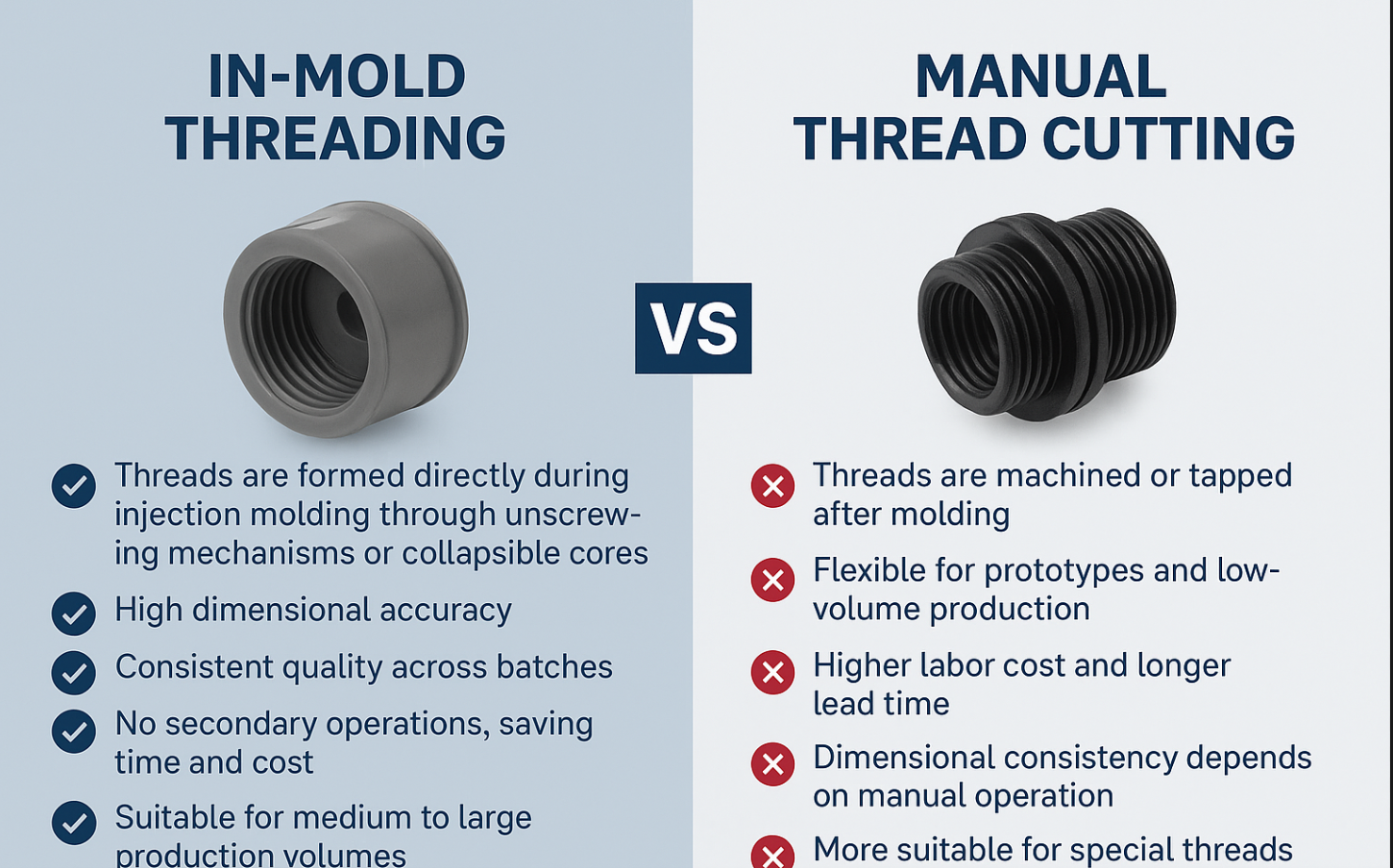

When it comes to plastic parts with threaded features, choosing the right manufacturing process makes a big difference in quality, efficiency, and cost.

🔹 In-mold Threading

Threads are formed directly during injection molding through unscrewing mechanisms or collapsible cores.

High dimensional accuracy

Consistent quality across batches

No secondary operations, saving time and cost

Suitable for medium to large production volumes

🔹 Manual Thread Cutting

Threads are machined or tapped after molding.

Flexible for prototypes and low-volume production

Higher labor cost and longer lead time

Dimensional consistency depends on manual operation

More suitable for special threads or limited quantities

👉 For long-term production, in-mold threading offers superior repeatability and efficiency. For prototypes or small runs, manual threading remains a practical solution.

At Rilong, we evaluate each project carefully to recommend the most efficient and reliable process for your parts.