In the pursuit of manufacturing excellence, every leap in precision begins with uncompromising measurement of the smallest details. We are dedicated to providing global clients with comprehensive precision metrology solutions, ensuring every component—from mold to final product—meets the most stringent specifications.

🔍 Our Core Measurement Capabilities: 10 experienced and qualified QC engineers work in our measurement unit.

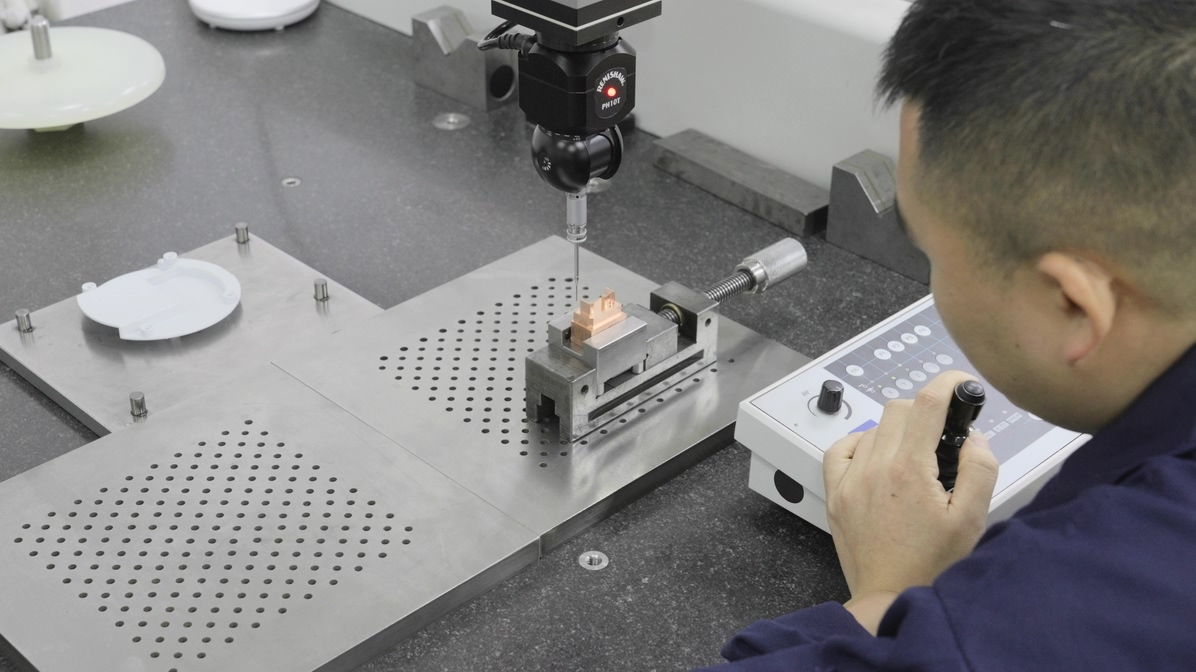

Globalplus CMM (Coordinate Measuring Machine)

- Guardian of Core Value: Engineered for complex geometries and supreme accuracy. Whether it’s large-scale molds, precision electrodes (copper cores), or critical product components, our CMM performs comprehensive, high-precision 3D measurement of dimensions and geometric tolerances. It provides the indisputable data foundation for your design and manufacturing, acting as the ultimate “Gatekeeper of Quality.”

CMM

Change this description

ElectronicCopper Measuring

Change this description

VMS (Video Measuring System)

- Efficiency for Process Optimization: In fast-paced production, speed and accuracy are equally vital. Our VMS offers rapid, non-contact 2D dimension and contour measurement, ideal for high-volume inspection of sheet metal parts, stampings, electronic components, and more. It serves as the “Quality Sentinel” on your production line, enabling real-time process control visualization and significantly boosting quality assurance efficiency.

VMS

Change this description

- Precision Gear Testing & Analysis

- Expertise in Transmission Excellence: The smooth, quiet, and reliable operation of any transmission system starts with perfect gear meshing. Our specialized gear testing services conduct in-depth analysis of core parameters like profile, helix, runout, and pitch. We go beyond identifying micro-errors to simulate real-world conditions for comprehensive performance analysis, helping optimize transmission performance and solve core issues like noise and wear.

Gear Measurment

Change this description

💡 We Deliver More Than Data—We Deliver Insight & Confidence:

We understand that the ultimate goal of measurement is improvement and assurance. By combining our expert team with advanced technology, we provide:

- Traceable Quality Records: Clear, professional inspection reports.

- Process Optimization Insights: Identify potential issues from data to drive manufacturing improvements.

- Dedicated Project Support: Full-scope support from inspection planning to high-volume implementation.

🤝 Let’s Partner for Precision:

Whether you are in mold making, precision machining, automotive, aerospace, electronics, or any industry where top-tier accuracy is non-negotiable, we are ready to be your most reliable quality partner.

📞 We welcome the opportunity to discuss your specific challenges or to provide detailed application notes.

Our company profile is attached for your reference (download link can be embedded).

Plastic factory: https://drive.google.com/file/d/1slbhTq_JWy5ufj3kXC7COovlaaYiTItp/view?usp=sharing

Company Profile: https://drive.google.com/file/d/1_qGJTXPx50_yJh1yfLmykE7p1xbMBpxa/view?usp=sharing

#PrecisionMetrology #QualityControl #CMM #DimensionalMeasurement #GearInspection #MoldMaking #PrecisionManufacturing #Industry4_0 #QualityAssurance #MetrologyServices #Manufacturing #Engineering