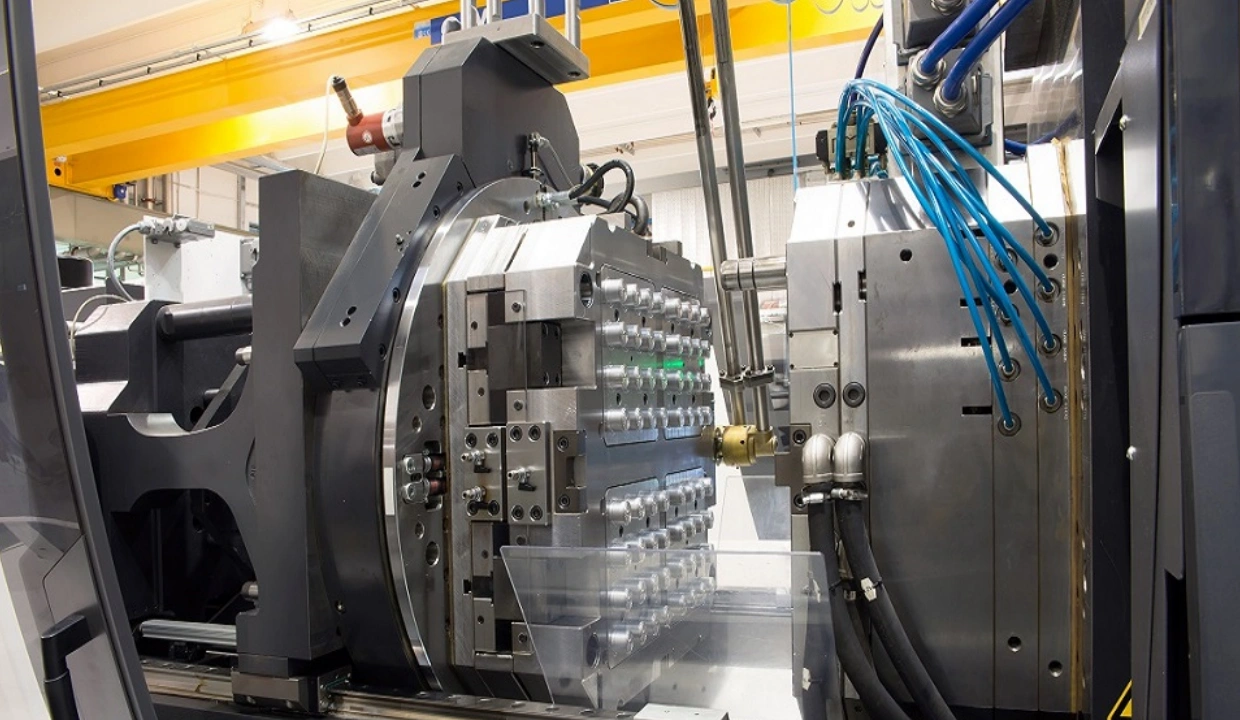

Injection molding is a versatile and widely used manufacturing process that has revolutionized the production of plastic parts. This method allows for creating complex shapes with high precision and efficiency, making it essential in various industries, from automotive to consumer goods.

What is Injection Molding?

Injection molding is a manufacturing technique where molten material, typically plastic, is forced into a mold cavity under high pressure. Once cooled and solidified, the part is ejected, resulting in a finished product that matches the mold’s shape. Here’s a brief overview:

- A versatile method for creating plastic parts.

- Widely used in various industries for mass production.

- Allows for complex shapes and high precision.

- Cost-effective for large-scale manufacturing.

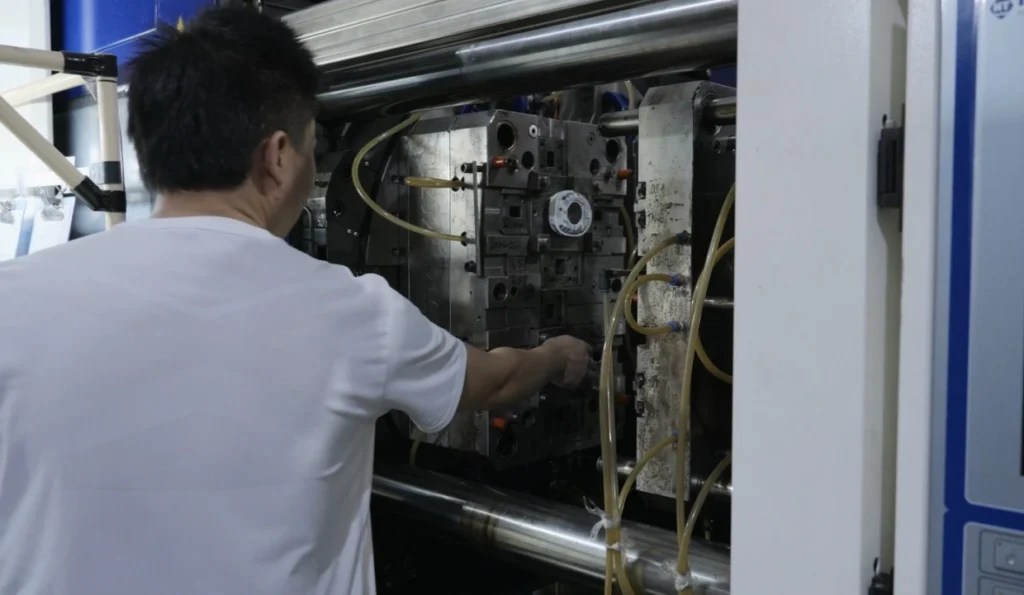

The Process

The process involves several key steps:

- Material Preparation: Plastic pellets are fed into a hopper.

- Melting: The pellets are heated and melted in a barrel.

- Injection: The molten plastic is injected into a mold cavity under high pressure.

- Cooling: The plastic cools and solidifies in the mold.

- Ejection: The finished part is ejected from the mold.

Advantages

Injection molding offers numerous benefits, including:

- High production rates

- Repeatability and consistency

- Ability to produce complex geometries

- Wide range of material options

- Cost-effectiveness for large-scale production

Applications

It is used in various industries to produce a wide array of products, such as:

- Automotive parts (dashboards, bumpers)

- Consumer goods (toys, household items)

- Medical devices (syringes, implants)

- Electronic components (casings, connectors)

- Packaging (bottles, containers)

Challenges and Considerations

While injection molding is highly efficient, it does come with some challenges:

- High initial tooling costs

- Potential for defects like warping or sink marks

- Material limitations

- Design considerations for proper mold filling

Future of Injection Molding

The mold industry continues to evolve with advancements in technology. Some emerging trends include:

- Integration of AI and machine learning for process optimization

- Use of sustainable and biodegradable materials

- Adoption of Industry 4.0 principles for smart manufacturing

- Improvements in mold design and cooling systems

In conclusion, injection molding remains a critical manufacturing process, continually adapting to meet the demands of modern production. Its versatility, efficiency, and potential for innovation ensure its place as a cornerstone of manufacturing for years to come.