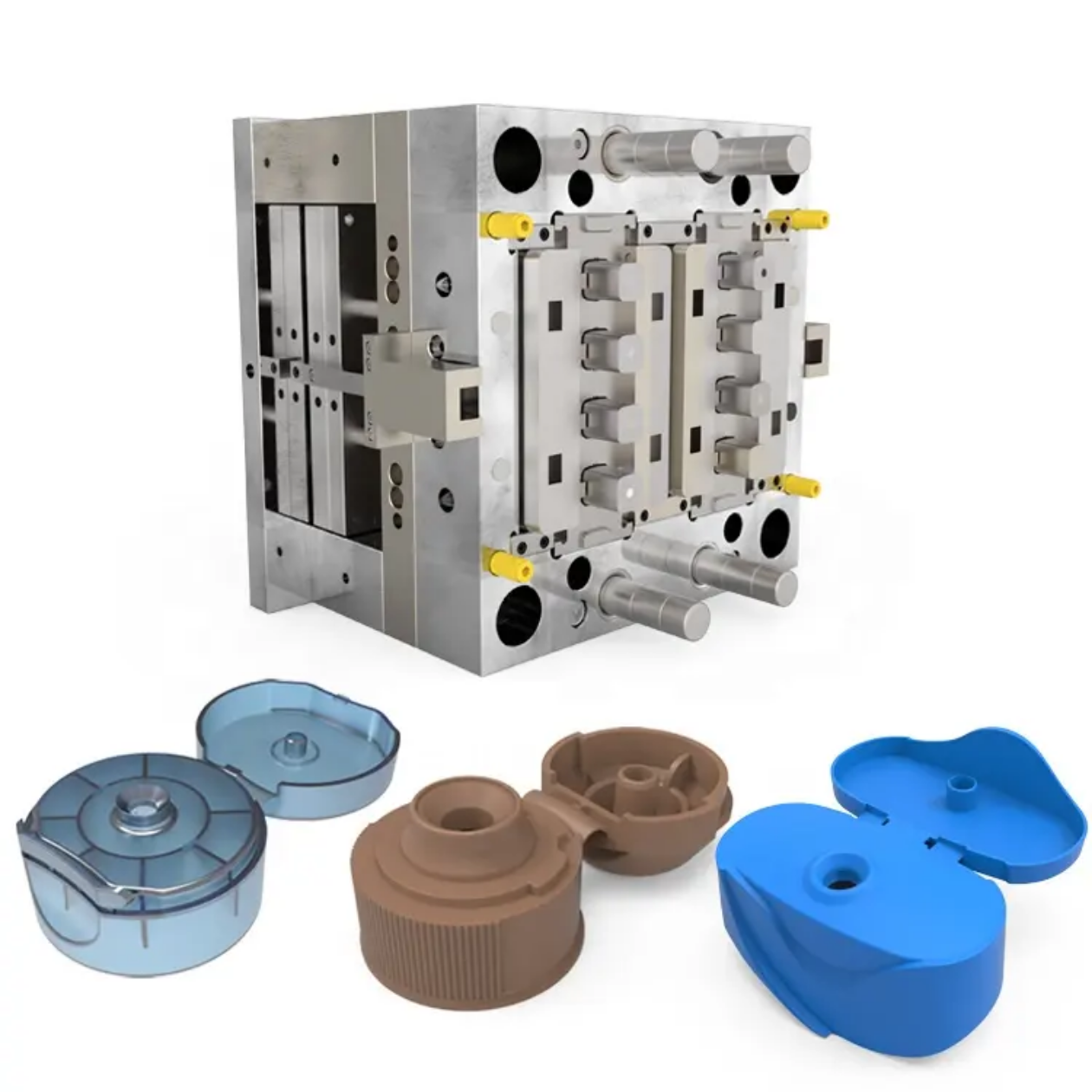

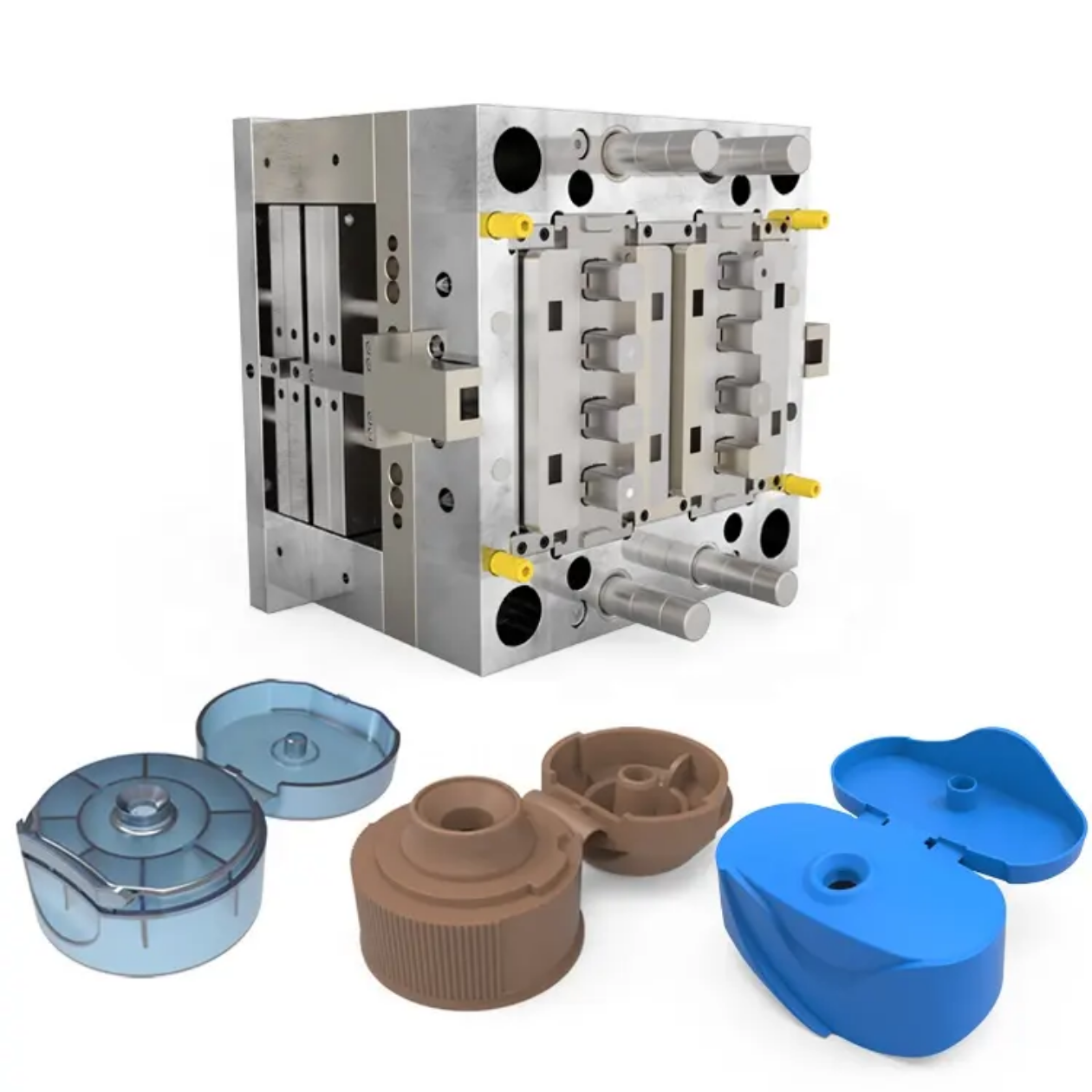

Introduction: When Innovative Design Meets Manufacturing Challenges

The drive for superior product functionality and aesthetics often leads to designs with internal undercuts, threads, or complex geometries. While these features enhance the user experience, they present a significant manufacturing hurdle: how can the part be ejected from the mold without damage?

Image Box Title

Change this description

Image Box Title

Change this description

The answer lies in advanced Collapsible Core Technology. At [日隆精密模具], our mastery of this sophisticated mold mechanism is what sets us apart and enables us to bring your most ambitious designs to life.

Image Box Title

Change this description

What is a Collapsible Core Structure?

A collapsible core is an intricate internal mold mechanism designed to form complex internal part features. Unlike traditional side-action sliders that move laterally, a collapsible core consists of multiple segments that are synchronized to collapse radially inward upon mold opening. This precise movement cleanly disengages from internal undercuts, allowing for the seamless ejection of the finished part without scuffing, stretching, or distortion.

Image Box Title

Change this description

Our Capability: Transforming Complex Challenges into Routine Production

At [Your Company Name], we don’t just build molds; we engineer solutions. Our technical expertise in collapsible core design and manufacturing is a cornerstone of our service offering.

- Precision Engineering & Simulation: Our engineering team utilizes state-of-the-art CAD/CAE software to simulate the core’s movement, timing, and structural integrity. This proactive analysis eliminates risk and ensures a flawless, reliable mechanism from the first shot.

- High-Accuracy Machining: The success of a collapsible core depends on micron-level precision. We employ advanced 5-axis CNC machining and precision EDM processes to manufacture every core segment and linking component to exacting tolerances, ensuring smooth, interference-free operation.

- Unmatched Durability & Stability: We understand the immense pressures these structures endure. We select premium-grade mold steels and apply specialized heat treatment processes to maximize wear resistance and longevity, guaranteeing consistent performance over high-volume production runs.

- Flexible Actuation Solutions: We tailor the drive mechanism to your needs—utilizing efficient angle-pin (mechanical) actuation for high-speed cycles or precise hydraulic cylinders for complex sequences—delivering the optimal solution for your project’s budget and requirements.

Image Box Title

Change this description

Ideal Applications:

- Internal Threads: Bottle caps, connectors (enabling high-speed ejection without unscrewing).

- Internal Undercuts: Cosmetic containers, housings, and consumer goods.

- Complex Industrial Components: Electronic components, automotive parts, and specialized functional assemblies.

Partner with Us for Your Most Demanding Projects

If your product design is being limited by internal complexity, don’t compromise. Let [RiLong Precision Mold] be your technical partner. We provide the expertise to transform your innovative concepts into high-quality, manufacturable products.

Ready to discuss your project? Contact our engineering team today for a consultation, and let’s push the boundaries of what’s possible together.