When discussing mold pricing with clients, one of the most common questions we hear is: “Can we use cheaper steel to reduce the mold cost?”

There’s a common misconception that the cost of an injection mold is primarily determined by the type of steel. While steel choice does affect the price to some extent, the main cost driver is actually the complexity of the product design—not the material.

Why Product Design Has a Bigger Impact on Mold Cost

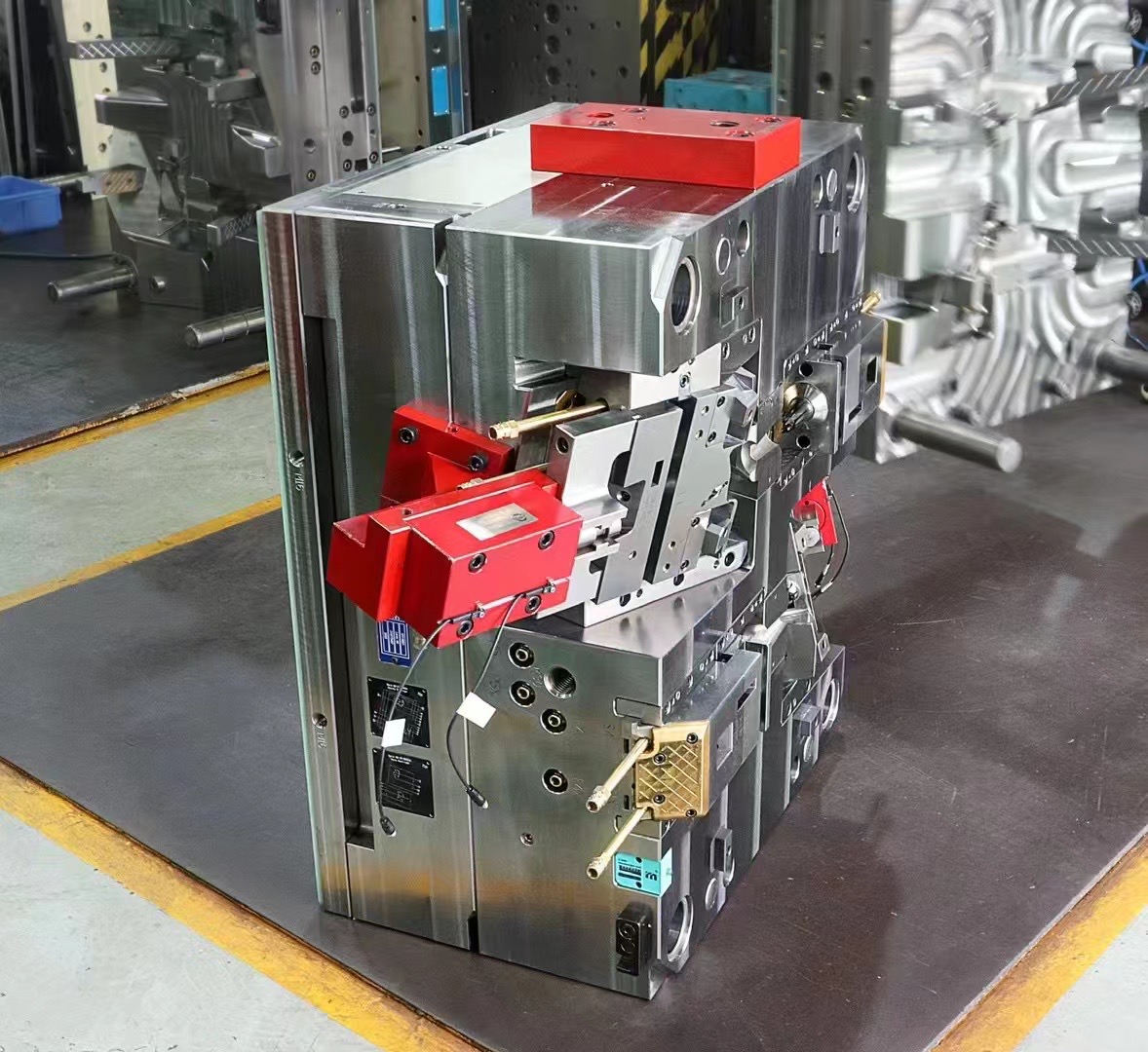

1. Complex Designs Require Complex Mold Structures

If a product has undercuts, snap fits, thin walls, or intricate shapes, the mold will need additional features like sliders, lifters, hydraulic cylinders, or unscrewing mechanisms. These increase the mold’s complexity and significantly add to the design and manufacturing time.

2. Precision Machining Takes Time and Resources

A simple part might only need basic CNC milling. But parts with mirror finishes, textures, or tight tolerances may require EDM, high-speed milling, or polishing—each of which adds time, labor, and cost to the mold-making process.

3. More Design Complexity Means More Testing and Adjustments

Intricate molds often need more trial-and-error during testing and fine-tuning. That includes resolving issues like flash, shrinkage, warping, or short shots. These troubleshooting efforts translate into engineering hours and time spent adjusting the mold.

So How Much Does Steel Actually Matter?

Steel selection definitely plays a role—whether you use P20, H13, S136, NAK80, or premium brands like ASSAB or LKM. However, steel cost usually accounts for only 10–20% of the total mold price, especially for small to medium-sized tools. Switching to a more expensive steel rarely leads to a dramatic price increase.

How to Control Your Mold Costs

- ✅ Simplify the product design where possible

- ✅ Involve your mold maker early for DFM (Design for Manufacturability) feedback

- ✅ Choose steel based on production volume and product life—not just quality perception

Final Thoughts

Injection molds are highly customized tools. Their cost reflects not just the materials, but also the engineering, precision, and craftsmanship that go into making them. So next time you’re evaluating a mold quote, start by looking at the product design—not just the type of steel.

Any innovation? Let’s Work Together