Two-shot molding, also known as multi-material or double injection molding, has redefined what’s possible in product design and production. By integrating two different materials or colors into a single process, two-shot molding offers unparalleled opportunities for innovation, efficiency, and quality. When combined with automation, the potential of this technology is amplified, enabling manufacturers to meet the evolving demands of global markets.

What Is Two-Shot Molding?

Two-shot molding involves injecting two different materials or colors into a single mold during two sequential steps. The result is a single, cohesive component with enhanced functionality, aesthetic appeal, or both. This technique is widely used in industries such as:

- Medical: Devices requiring ergonomic grips and transparent sections.

- Automotive: Buttons, seals, and dashboards with dual-material needs.

- Consumer Electronics: Sleek, functional designs with tactile and visual contrasts.

Why Automate Two-Shot Molding?

Automation in two-shot molding streamlines production reduces costs, and ensures consistent quality. Here are the key benefits:

1. Improved Efficiency

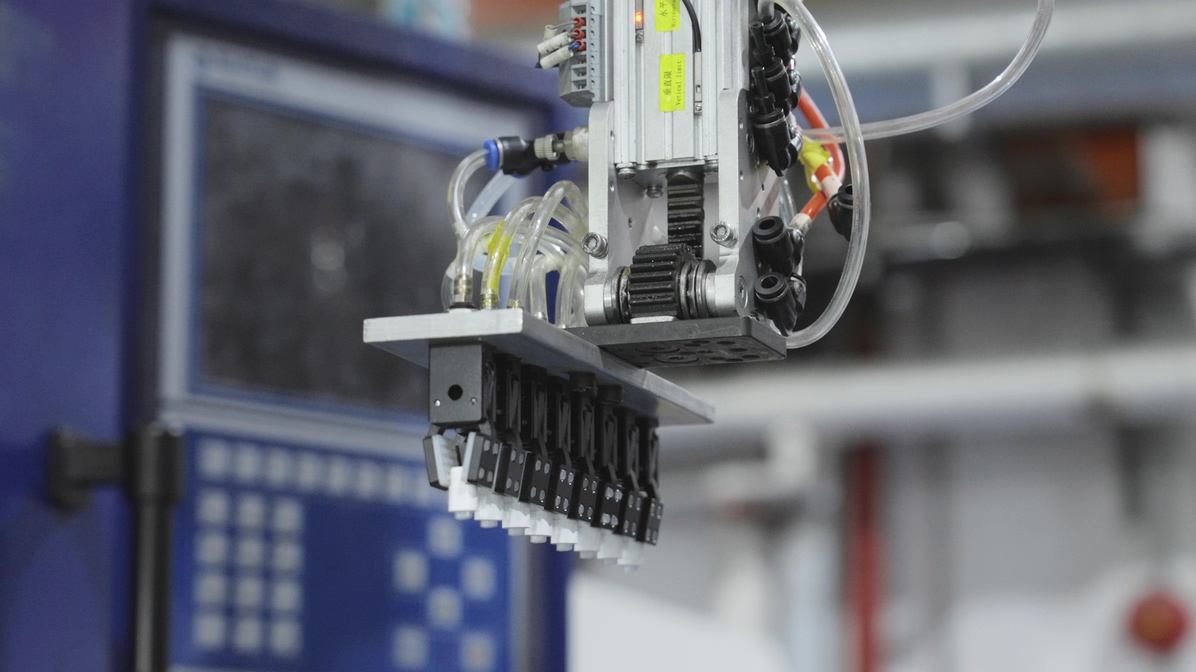

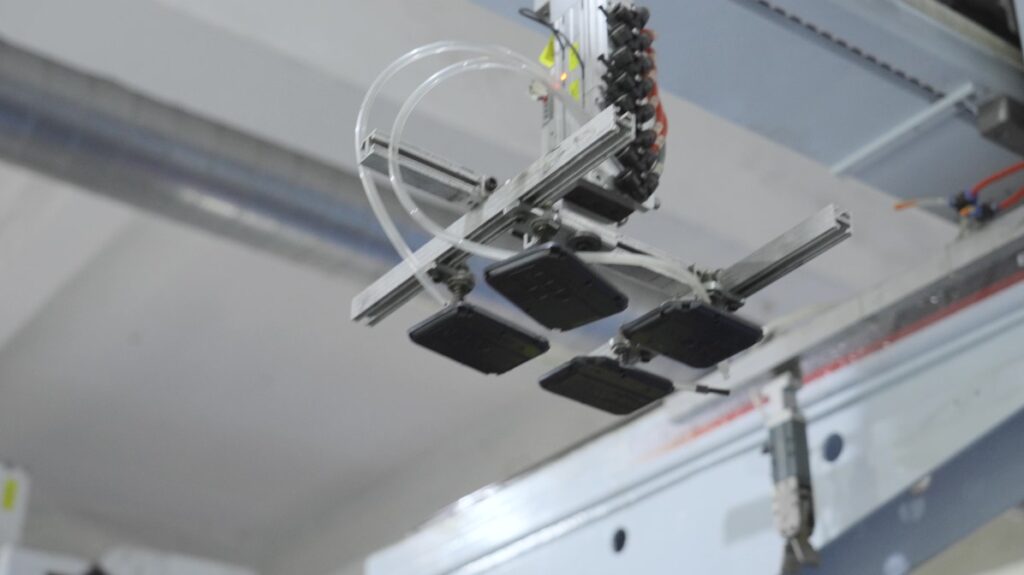

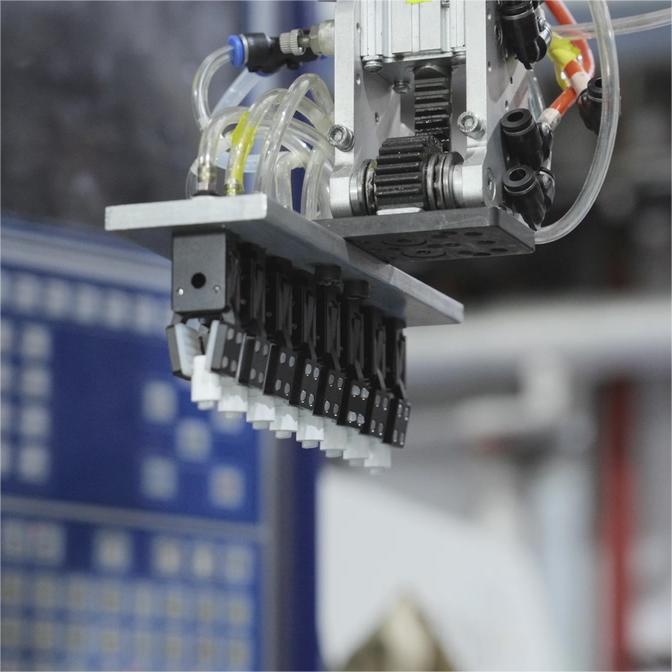

Automation eliminates manual handling between molding cycles. Robots and automated systems ensure precise material transfer and alignment, significantly reducing cycle times and boosting production output.

2. Enhanced Precision and Quality

Automated systems ensure perfect alignment and injection accuracy, reducing defects such as flash, warping, or misalignment. This level of precision is critical in high-demand industries like medical devices and automotive components.

3. Cost Savings

By reducing material waste, labor costs, and production errors, automation helps achieve long-term cost efficiency. While the initial investment in automated equipment may be high, the ROI is substantial through increased productivity and reduced defects.

4. Versatility for Complex Designs

Automation allows manufacturers to handle intricate designs with ease, enabling the production of components with multiple materials, textures, and functionalities in a single process.

Applications of Automated Two-Shot Molding

Rilong Precision Mold delivers high-precision two-shot molding solutions tailored to diverse industries. Examples of our capabilities include:

- Medical Devices: Transparent and tactile components for better usability.

- Consumer Electronics: Durable, multi-functional parts with sleek finishes.

- Industrial Components: High-performance seals and grips for demanding environments.

Our Commitment to Excellence

Integrating automation into our two-shot molding processes ensures that our clients receive the highest quality products with shorter lead times. Our state-of-the-art facilities are equipped with advanced robotics and precision molding machines, allowing us to tackle projects of any complexity.

Let’s Build the Future Together

Whether you’re looking to enhance your product’s design, functionality, or manufacturing efficiency, automated two-shot molding can be the key to your success. Contact us today to discuss your project requirements and explore how we can bring your ideas to life.

RiLong Precision Mold Founded in 1990, we are a leader in high-precision plastic and rubber molding, serving industries worldwide. With a focus on innovation and quality, we deliver solutions that meet the highest industry standards.