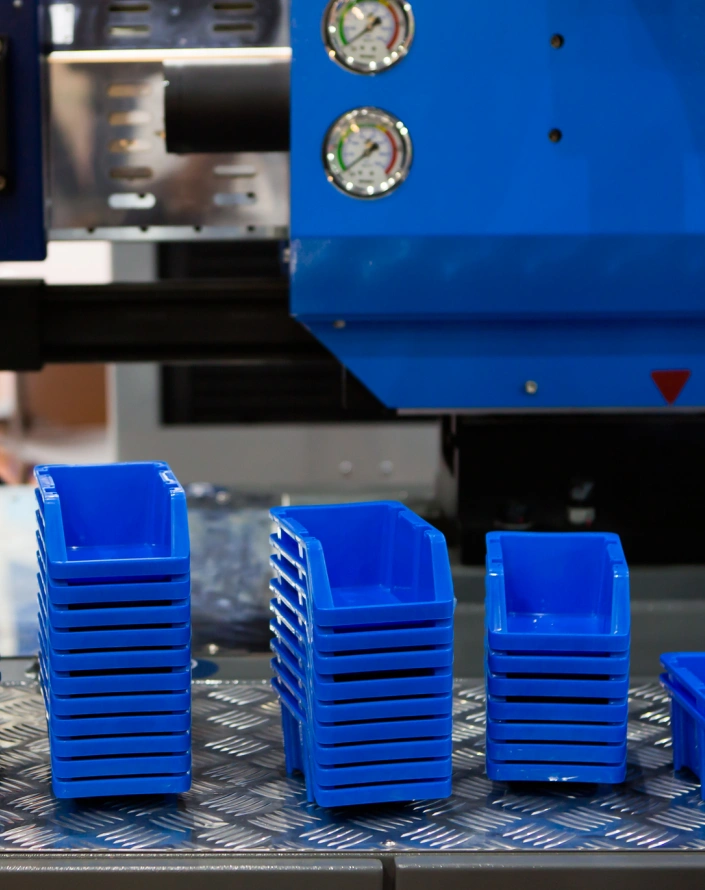

Selecting the right material is critical for the success of any injection molding project. With a wide range of materials available, each offering unique properties and characteristics, it’s essential to understand the options and considerations involved. In this comprehensive guide, we’ll explore the most common injection molding materials, their properties, applications, and factors to consider when selecting the optimal material for your project.

- Thermoplastics: Thermoplastics are the most widely used materials in injection molding due to their versatility, ease of processing, and recyclability. Common thermoplastics used in injection molding include:

- Polyethylene (PE): PE is a lightweight, durable thermoplastic with excellent chemical resistance, making it suitable for a wide range of applications, including packaging, containers, and automotive components.

- Polypropylene (PP): PP offers a good balance of stiffness, impact resistance, and chemical resistance, making it ideal for applications such as consumer goods, medical devices, and automotive parts.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a tough, impact-resistant thermoplastic commonly used in applications requiring strength and durability, such as electronics, appliances, and automotive interiors.

- Polycarbonate (PC): PC is a transparent thermoplastic known for its high impact strength, heat resistance, and optical clarity, making it suitable for applications such as lenses, housings, and automotive lighting.

- Thermosets: Thermoset materials undergo a chemical reaction during molding, resulting in a cross-linked, rigid structure that cannot be re-melted or reshaped. Common thermoset materials used in injection molding include:

- Phenolic Resin: Phenolic resin offers excellent heat resistance, electrical insulation, and dimensional stability, making it suitable for applications such as electrical components, appliance handles, and automotive parts.

- Epoxy Resin: Epoxy resin is known for its high mechanical strength, chemical resistance, and adhesive properties, making it ideal for applications requiring structural integrity and corrosion resistance, such as aerospace components and industrial parts.

- Elastomers: Elastomeric materials, also known as rubbers or elastomers, exhibit elastic behavior and can undergo significant deformation without permanent deformation. Common elastomeric materials used in injection molding include:

- Silicone Rubber: Silicone rubber offers excellent temperature resistance, flexibility, and biocompatibility, making it suitable for medical devices, seals, gaskets, and automotive components.

- Thermoplastic Elastomers (TPE): TPEs combine the properties of thermoplastics and elastomers, offering flexibility, resilience, and ease of processing. They are used in applications such as consumer products, automotive seals, and medical devices.

Considerations for Material Selection: When selecting an injection molding material, several factors should be considered:

- Mechanical Properties: Consider the desired strength, stiffness, impact resistance, and flexibility of the final part.

- Environmental Factors: Evaluate the material’s resistance to temperature, chemicals, UV exposure, and environmental conditions.

- Aesthetics: Consider the desired surface finish, color, and transparency of the final part.

- Regulatory Compliance: Ensure that the selected material meets industry standards and regulatory requirements for safety, performance, and environmental sustainability.

Conclusion: With a diverse array of materials available for injection molding, choosing the right material is essential for achieving optimal performance, quality, and cost-effectiveness. By understanding the properties, applications, and considerations associated with each material type, manufacturers can make informed decisions and unlock the full potential of injection molding technology for their projects. Whether it’s creating durable consumer products, precision medical devices, or high-performance automotive components, selecting the right material is the first step towards success in injection molding.