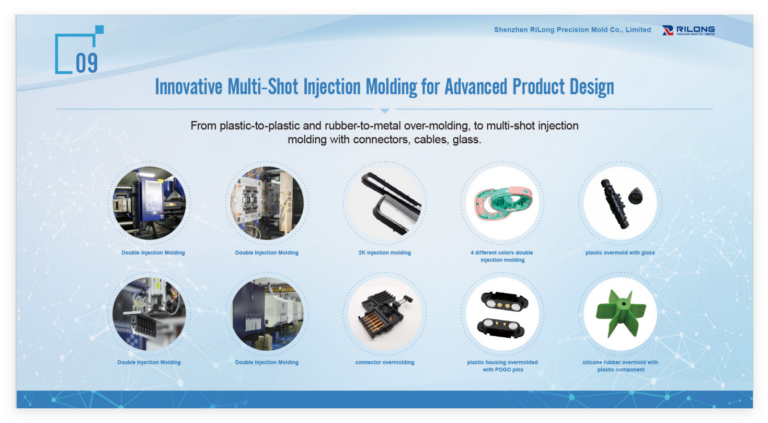

Process Showdown: Two-Shot Molding vs. Overmolding — Cost, Efficiency & Selection Logic

Incorporating multi-material designs (e.g., rigid plastic + soft TPE) into products not only enhances grip comfort but also adds functionalities such as waterproofing and shock absorption. However, choosing between Two-Shot Molding and Overmolding is often the first major challenge engineers…