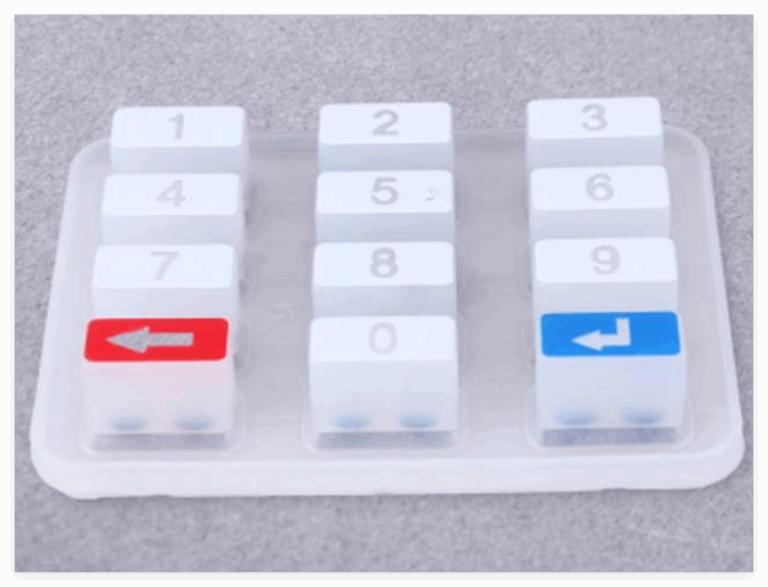

How to Laser-Etch Patterns on Light-Through Buttons Without Compromising Transparency

Achieving crisp backlit symbols on light-transmitting buttons requires precision laser technology. Standard laser etching often carbonizes the substrate, reducing light transmission by over 50%. Discover how our specialized process delivers flawless results while preserving 90%+ light throughput. 1. The Industry…