Surface finishing is a critical step in the manufacturing of plastic products, impacting not only the appearance but also the performance and functionality of the final product. At RiLong Precision Mold Co., Limited, with over 30 years of experience in the industry, we want to share some practical insights about different types of surface finishes and how they can benefit your products.

What is Surface Finishing?

Surface finishing refers to the process applied to the outer layer of a plastic part to achieve a specific look, feel, or function. It can range from a simple, smooth polish to a complex texture or coating that enhances the product’s aesthetic and functional properties.

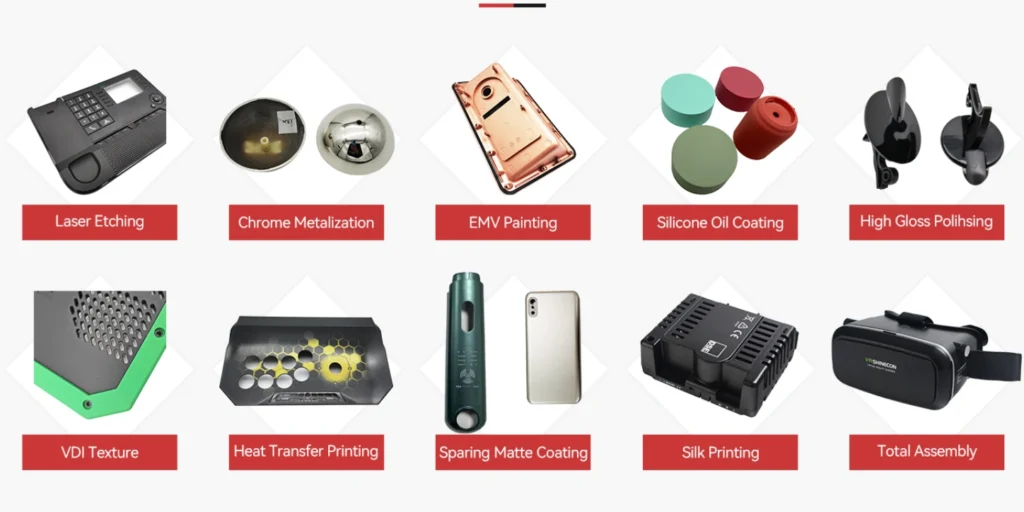

Common Types of Surface Finishing for Plastic Products

1. Polishing: This creates a smooth, glossy surface, ideal for products where appearance is key, such as consumer electronics or automotive interiors. Polished surfaces are easier to clean and can resist dirt and moisture.

2. Texturing: Adds a fine or coarse texture to the surface, which can enhance grip, reduce glare, or provide a specific look. This is often used in household appliances, tools, or medical devices to improve usability.

3. Matte Finish: Provides a non-reflective surface, which is excellent for products that should not attract fingerprints or show scratches, such as mobile phone cases or dashboard components in vehicles.

4. Painting and Coating: This involves adding a layer of paint or special coating to enhance the product’s appearance, add color, or provide additional protection from UV rays, chemicals, or abrasion. Common in automotive and outdoor products.

5. Laser Etching: Used to create precise designs, logos, or markings on the product surface. This is perfect for branding, serial numbers, or user instructions on various consumer products.

6. Plating and Metallization: Adds a thin layer of metal to a plastic surface, giving it a metallic look while maintaining the lightweight properties of plastic. Commonly used in electronics, automotive, and decorative products.

How Does Surface Finishing Impact Your Product?

Aesthetic Appeal: The right finish can significantly enhance the look of your product, making it more attractive to customers and more competitive in the market.

Functionality: Different finishes can improve grip, reduce friction, or make the product easier to clean, directly impacting user experience.

Durability: Certain surface treatments can protect the product from UV damage, chemical exposure, or wear and tear, extending its lifespan.

Brand Differentiation: Unique finishes can set your product apart, providing a distinctive appearance that aligns with your brand identity.

Choosing the Right Surface Finish for Your Product

Choosing the best surface finish depends on various factors, including the product’s function, target market, material, and desired aesthetic. At RiLong Precision Mold Co., Limited, our team of experts can help you determine the most suitable option based on your project requirements.

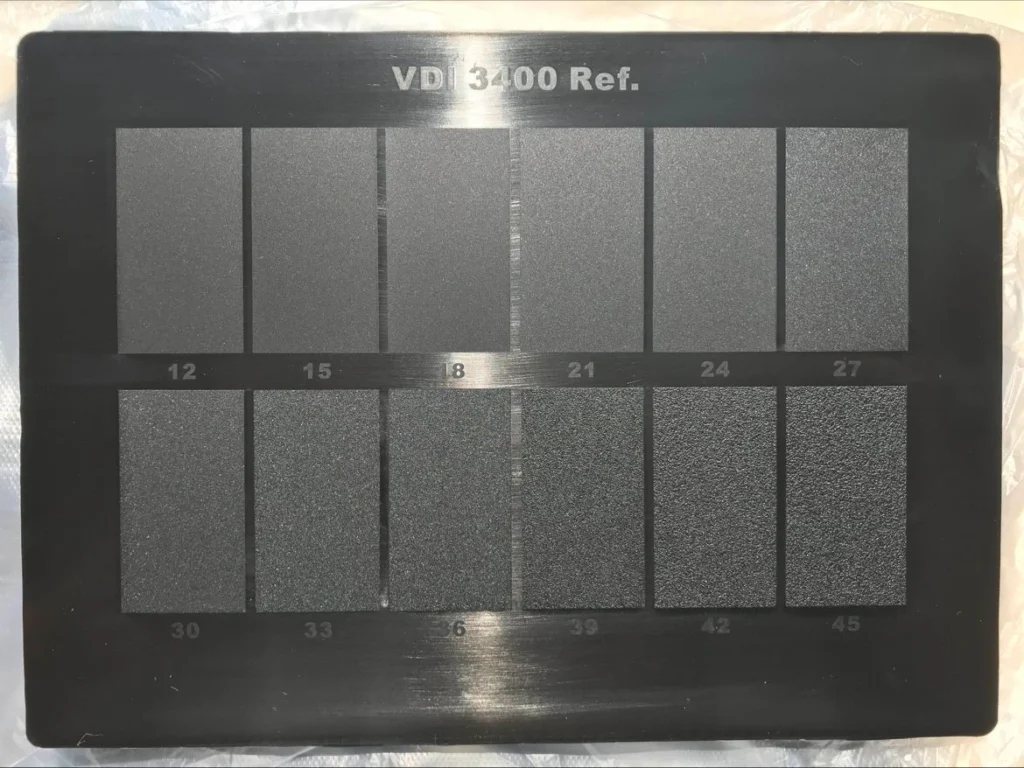

If you are unsure about the specific texture or grain pattern you need for your new project, we can provide texture samples to help you visually confirm the exact model. We offer samples with various standard finishes such as VDI, SPI, and YS. If you need samples, please feel free to contact us!

Contact Us for Customized Surface Finishing Solutions

At RiLong Precision Mold Co., Limited, we offer a variety of surface finishing options tailored to your needs. Whether you need a high-gloss polish, a textured grip, or a protective coating, we can deliver the perfect solution to enhance your product’s appeal and performance.

Interested in learning more? Contact us today to discuss how we can help make your product stand out in the market!