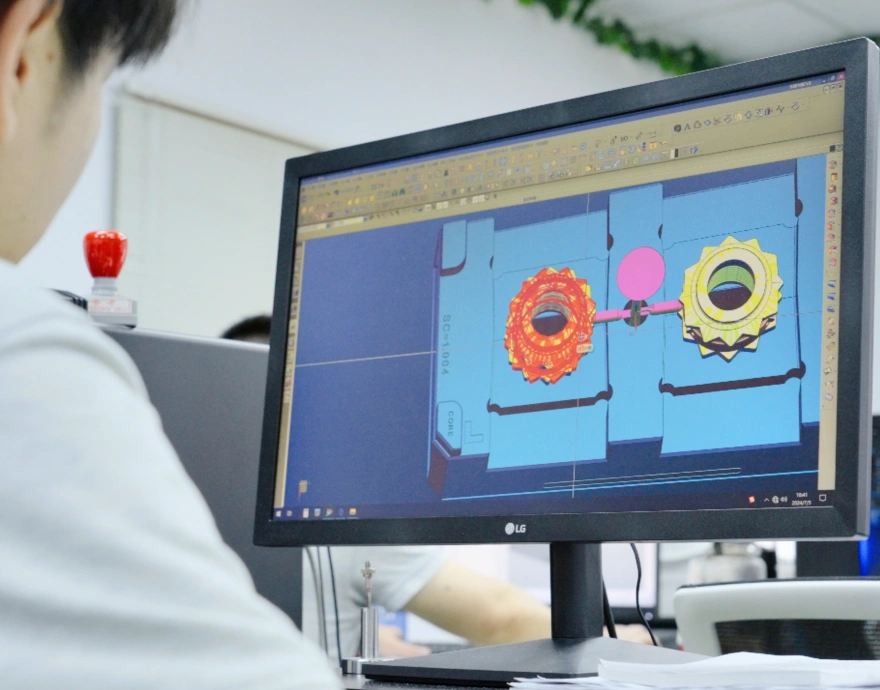

Mold Design and Production

Choose Rilong for Your Mold Design and Manufacturing Needs

Rilong’s distinctive, mold-maker-friendly approach differentiates us from the competition. We bring you a combination of the best resources available: advanced technology, superior craftsmanship, and adaptable program management and product development techniques tailored to accommodate unique, multi-cavity, and multi-mold programs.

We maintain a diversified capability in a broad range of markets. Our focus is on supporting global mold programs for healthcare, automotive, consumer, and industrial markets.

Diverse Array of Mold Structures

Rilong’s high-performance injection molds seamlessly blend craftsmanship with technology. These products, which combine innovation and artistry, are a testament to our dedication and pride.

Mold Production Process

Rilong’s Program Management Team members are industry-seasoned tool designers and tool makers.

01

Mold Design and Preparation

• Pro Engineer Drafting

• DFM/Mold Flow Confirm

• Order steel

• Prepare accessories

02

Mold-Making

• Heat treatment

• Rough machining

• Polishing and Finish

• EDM and wire EDM

• Precise CNC machining

03

Mold Fitting and Testing

04

Mold Trial

Production Equipment of Tooling Department

Rilong excels in delivering top-tier, tailor-made solutions. With our expertise in on-demand injection molding, we provide high-quality prototypes and production parts to meet your unique requirements.

| Item | NO | Equipment Item | Brand | Quantity | Property | |||

| Tachometer/speedometer | Accuracy | MM | ||||||

| Process Equipment | 1 | CNC | ChaoQun | 1PCS | 8000/MIN | 0.01 | 850*650*900 | |

| Frank | 2PCS | 2.4W/MIN | 0.005 | 500*400*400 | ||||

| Seiki | 2PCS | 2.6W/MIN | 0.005 | 600*400*400 | ||||

| Charmilles | 1PCS | 1.4W/MIN | 0.005 | 850*650*400 | ||||

| 2 | Wire-cut machine | Wire-cut | SODICK | 1PC | 0.005 | 300*250*180 | ||

| Charmilles | 1PC | |||||||

| Speediness wire-cut | Jin Teng | 1PC | 500*400*350 | |||||

| YIGUANG | 1PCS | |||||||

| YIGUANG | 1PCS | |||||||

| 3 | EDM | SODICK | 1PCS | 0.005 | 500*400*200 | |||

| SODICK | 1PCS | 0.005 | 500*400*200 | |||||

| Charmilles | 2PCS | |||||||

| XingFeng | 3PCS | 0.01 | 600*500*300 | |||||

| TaiYi | 2PCS | |||||||

| 4 | Milling machine | DaYou | 4PCS | 5000/MIN | 0.02 | 800*500*120 | ||

| Heng yu | 2PCS | 5000/MIN | 0.02 | 800*500*120 | ||||

| 5 | Grinding machine | JianDe | 3PCS | 3600/MIN | 0.002 | 450*250*300 | ||

| Hangzhou machine | 1PCS | 3600/MIN | 0.002 | 450*250*300 | ||||

| YuQing | 2PCS | |||||||

| BaoCheng | 1PCS | 3600/MIN | 0.002 | 450*250*300 | ||||

| 6 | Grinding machine | Hangzhou machine | 1PCS | 1400/MIN | 0.002 | 400*1000*300 | ||

| 7 | Turning | XingYuan | 1PCS | 1600/MIN | 0.01 | 1500*300 | ||

Our Advantages

Rilong is your trusted partner for injection mold design and on-demand manufacturing solutions.

Searching for exceptional custom molded parts? Look no further, Get a Free Consultation!

Cost-effective

Our team consistently meets production demands with cost-effective solutions. From design optimization and steel selection to mechanism enhancement and robot-aided molding production, we contribute to your project’s success with our mold-making expertise.

Cutting-edge equipment

Equipped with imported high-precision CNC machining, spark machines wire wire-cutting equipment, and precision grinders, the mold production center ensures high precision.

Quality Exceeds Expectation

We use steel and mold bases exclusively from recognized brands like LKM, Groeditz, and ASSAB. Each piece of steel for core and cavity inserts is traceable and comes with specifications from the manufacturer.

Proven Success

Rilong has garnered thousands of satisfied clients worldwide. Over the past 30 years, we have assisted our customers in developing and shipping millions of custom-molded parts.