Overmolding and Insert Molding

Enhancing Your Products by Overmolding

With advanced technical skills and extensive material knowledge, we can tackle the most complex and demanding projects.

Overmolding &Insert Molding of Exquisite Quality

Materials of Overmolding and Insert Molding

The General materials listed below are for custom insert and over-molded plastic injection.

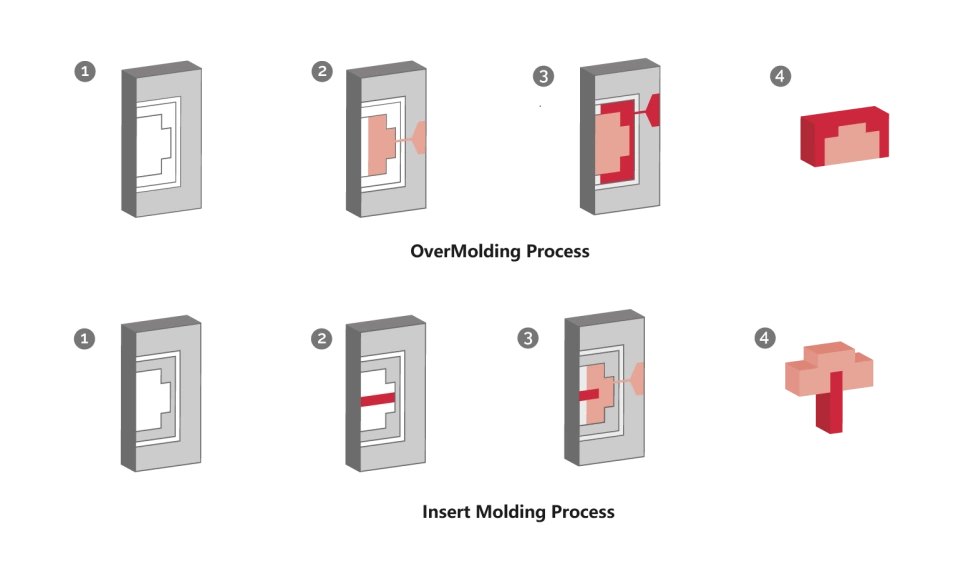

Overmolding vs Insert Molding

The overmolding and insert molding processes are specialized injection molding techniques used to integrate multiple materials or components into a single molded part.

Overmolding

Overmolding molds a material layer over an existing part to enhance aesthetics, grip, or functionality. After substrate parts are molded, they are manually placed into the overmold tooling for thermoplastic or silicone rubber molding.

It is commonly used for tool handles, electronic device covers, toothbrushes, and razors. It’s ideal for creating parts with a soft, flexible outer layer over a rigid base

Insert Molding

Insert molding is a similar process, but it involves using a preformed part, often made of metal, which is placed into the mold. This preformed part is then overmolded with a thermoplastic resin to create the final component.

Suitable for applications requiring strength and conductivity, such as electrical components, automotive parts, and medical devices. It’s used to enhance the structural integrity and durability of the final product.

Transforming Your Ideas Into a Reality

Concept to distribution, We get it done

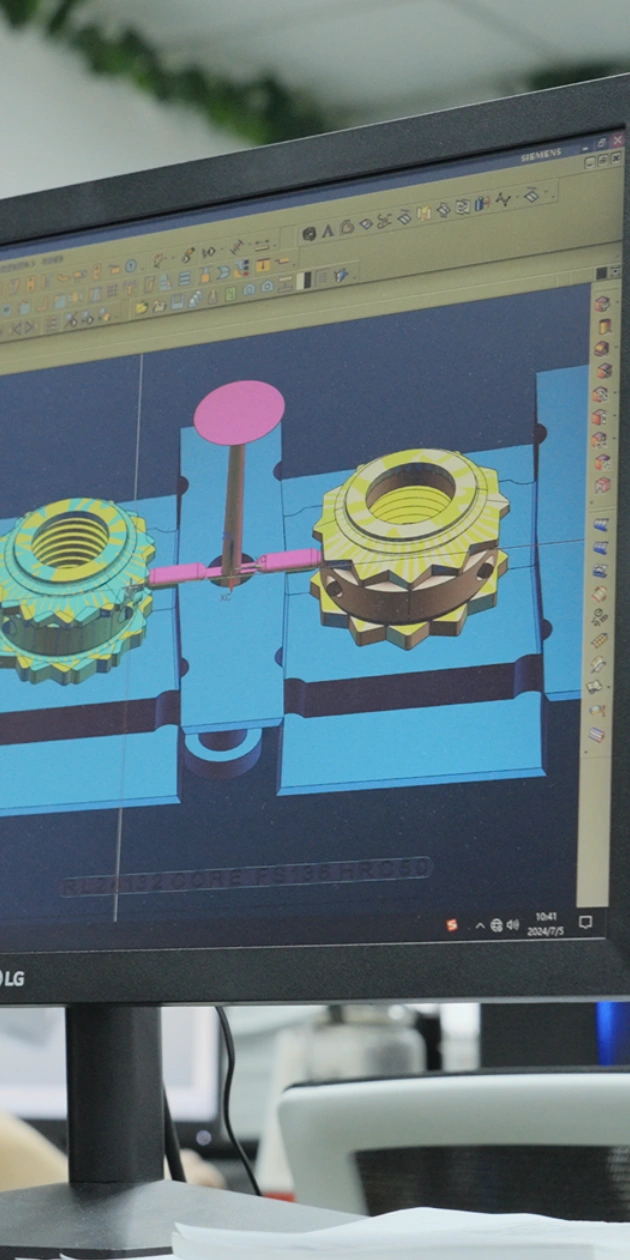

DESIGN

From initial sketches to detailed CAD/CAM designs, our team of skilled technical designers and engineers will expertly guide you in preparing your component for the molding process.

MANUFACTURING

Our multiple facilities, equipped with the latest technology and staffed by experienced professionals, ensure that we meet a wide range of production needs with precision and efficiency.

FULFILLMENT

Rilong offers global distribution services through our three strategically located warehouses in Shenzhen, Dongguan, and Zhuhai. This ensures timely delivery, regardless of your location.

Customer-Focused Partnership

At Rilong, we design and develop new product molds based primarily on our customers’ ideas. We take pride in listening to customer feedback and implementing their innovations, ensuring that their vision is brought to life.

Leaders in Innovation

Rilong Precision Mold supports this rapid pace by developing and building advanced tools that ensure we remain at the forefront of the industry, consistently leading with innovation and excellence.