纳米注塑成型:常见于手机和电脑外壳,但它到底是什么?

1.金属与弹性体的结合

在这个过程中,金属表面会被涂上一层特殊涂层,在放入模具前部分固化。然后注入热塑性弹性体(TPE),与金属形成一个统一的结构。

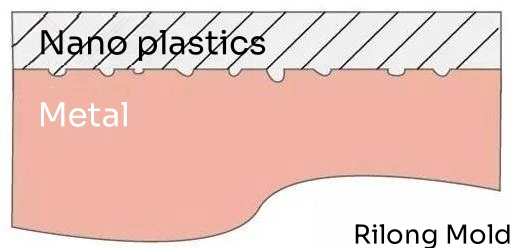

2.刚性塑料与金属的结合

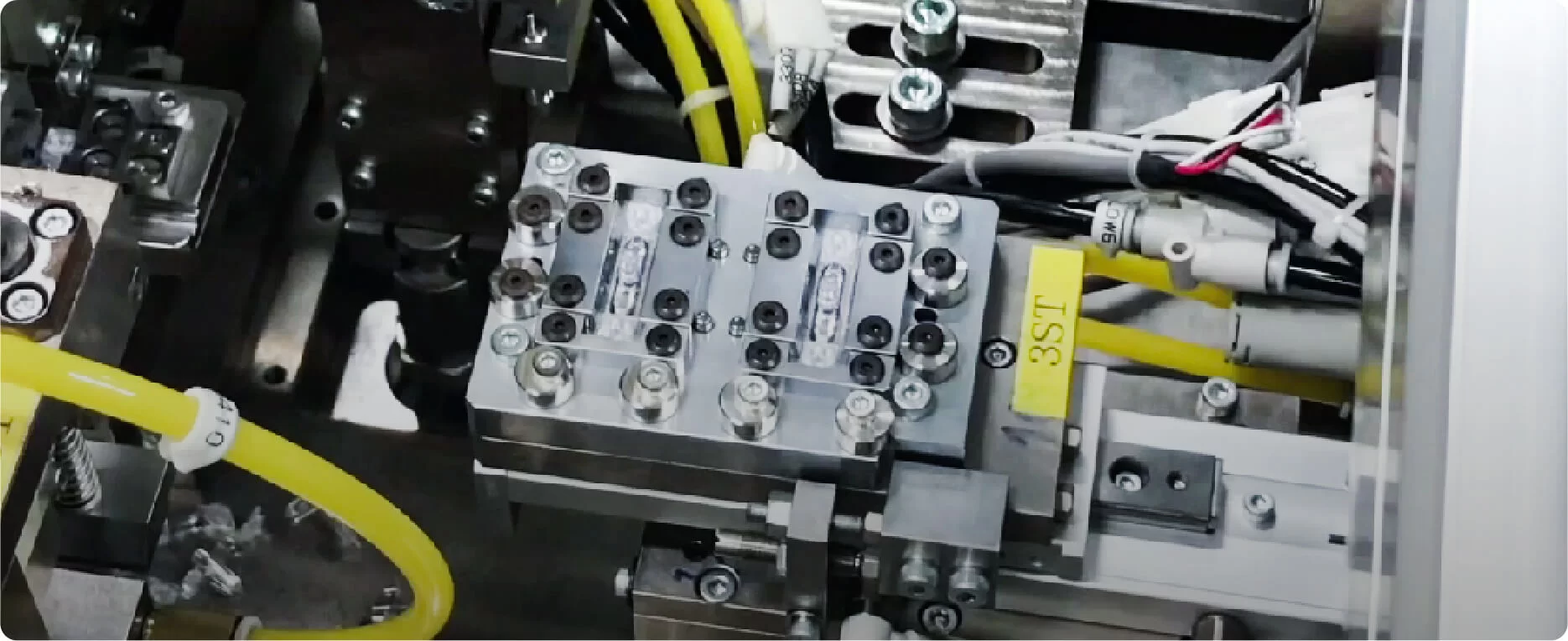

如今,纳米注塑成型可以粘合各种金属,包括铝、镁、铜、不锈钢、钛、铁和黄铜。可用的树脂包括 PBT、PPS(如 FORTRON®)、尼龙-6 和尼龙-66。由于金属和树脂的线性热膨胀系数不同,因此在树脂中添加玻璃纤维和填料,以使塑料的热膨胀率与金属匹配,从而防止粘合界面的剥离或损坏。这种结合方式既不是粘合剂粘接,也不是化学结合,而是物理融合。纳米注塑成型机的料筒比传统机器略小且更精确。

3. 纳米注塑成型的未来前景

纳米注塑成型有哪些优势?NMT(纳米成型技术)简化并缩短了制造流程,无需使用粘合剂即可将镁合金等材料粘合,减少了不必要的表面处理。此外,该技术可回收且安全,对环境影响极小。由于这些优势,纳米注塑成型正逐渐成为制造业的热门选择。富士康、比亚迪和日龙模具等行业领导者正在大力投资NMT研究,凸显了其重要性。

工程塑料如何与金属粘合?

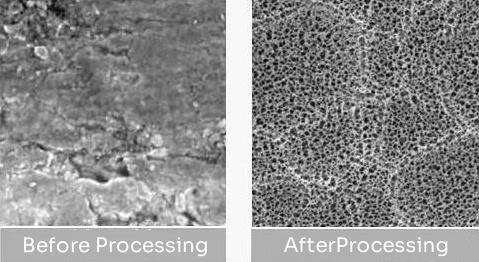

在对金属表面进行纳米处理后,将纳米塑料注入经过处理的铝合金中,填充合金中的微小凹坑,形成紧密结合的结构,具有高粘合强度,并且能有效抵抗液体和气体的渗透。

通过电子显微镜观察,经过处理的金属表面不仅保持了金属质感,还简化了产品设计,使产品更轻、更薄、更短、更小。与CNC加工相比,纳米注塑成型具有更高的成本效益。