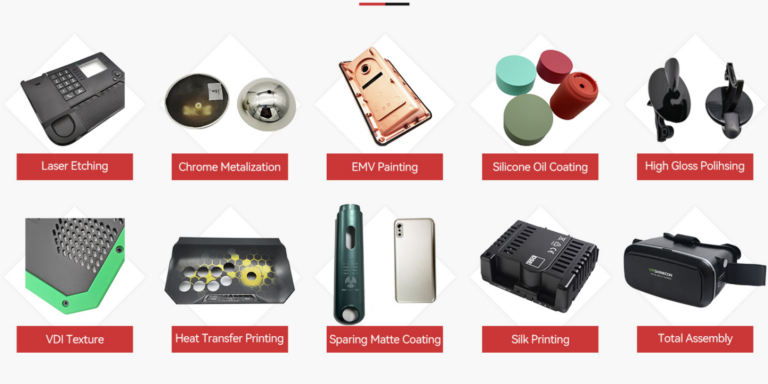

Beyond Injection Molding: 7 Surface Finishing Techniques That Elevate Product Quality

Injection molding brings your product to life—but surface finishing gives it soul. For plastic parts, the real differentiator between “ordinary” and “premium” often lies in the post-molding treatment. The same ABS or PC material can feel like metal, ceramic, or…