مدونة

Mastering Three-Dimensional Precision | Comprehensive Metrology Solutions for Your Critical Dimensions

In the pursuit of manufacturing excellence, every leap in precision begins with uncompromising measurement of the smallest details. We are dedicated to providing global clients with comprehensive precision metrology solutions, ensuring every component—from mold to final product—meets the most stringent…

Beyond Making New Molds: We Also Welcome Your Existing Tooling for Production

At Rilong Precision Mold, we understand the value of your tooling assets. Whether you already have a proven mold or are planning a new project, we are committed to being your reliable manufacturing partner. We not only provide custom new…

30 Years in Mold Making: Why Time is Your Greatest Assurance with an Overseas Partner

For international clients, choosing a long-established supplier isn’t about nostalgia—it’s a strategic decision for reliability, reduced risk, and peace of mind. When evaluating a mold maker on the other side of the world, a “30-year history” is more than a…

Reliable Transfer-Ready Molds for Global Production — Precision, Experience, and Quality Assurance

Building Confidence in Transfer-Ready Mold Manufacturing Yes, we can manufacture molds suitable for Global Production — and more importantly, we design and build them with transfer-readiness and long-term production stability in mind. For customers who plan to transfer molds to…

Handle Cover Material Showdown: Silicone vs. TPE/TPU—Why We Offer Two Different Solutions?

In overmolding projects for consumer electronics, tool handles, sports equipment, and more, the material selection for handle covers directly determines the product’s feel, durability, and user experience. While many assume “silicone is synonymous with soft touch,” TPE/TPU (thermoplastic elastomers) are increasingly becoming the preferred…

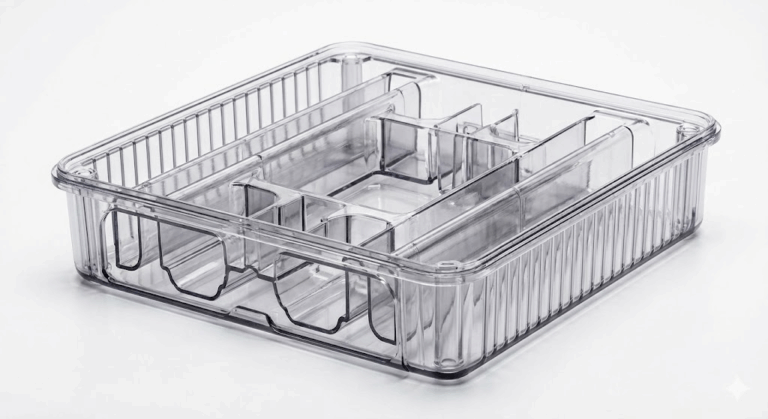

Hollow Injection-Molded Parts: Challenges and How to Ensure Quality

Hollow plastic parts are among the most challenging to manufacture due to internal cavities and a lack of support. They are prone to warpage, uneven shrinkage, sink marks, surface waviness, and dimensional instability—issues that can affect assembly, sealing, and product…

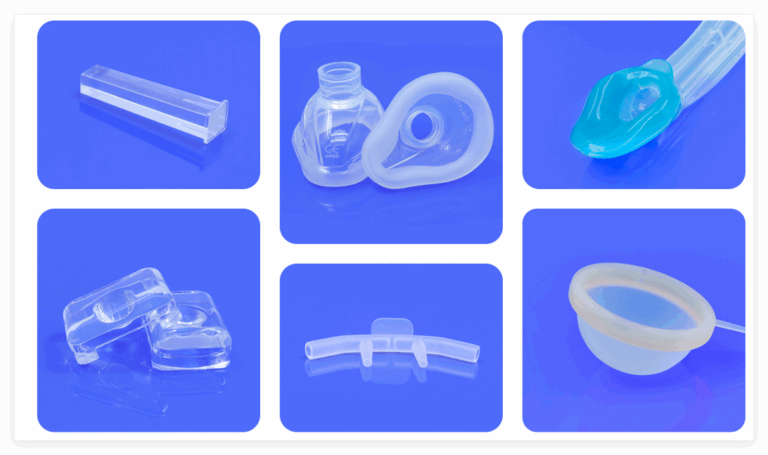

Innovate with Confidence: End-to-End Medical Silicone Solutions

Material Selection: The Cornerstone of Performance and Safety in Medical Devices In the medical device industry, material selection is fundamental to product performance, safety, and ultimate success. As your trusted partner, [RiLong Precision Mold] is committed to providing comprehensive medical…

Why Global Brands Choose Rilong: Our 30+ Years of Manufacturing Innovation

With over 30 years of manufacturing experience, Rilong specializes in mold design, development, and production for plastic and rubber molds and products. Our expertise covers hard and soft plastic over-molding parts, soft plastic and metal over-molding parts, double injection, LSR/LSR…

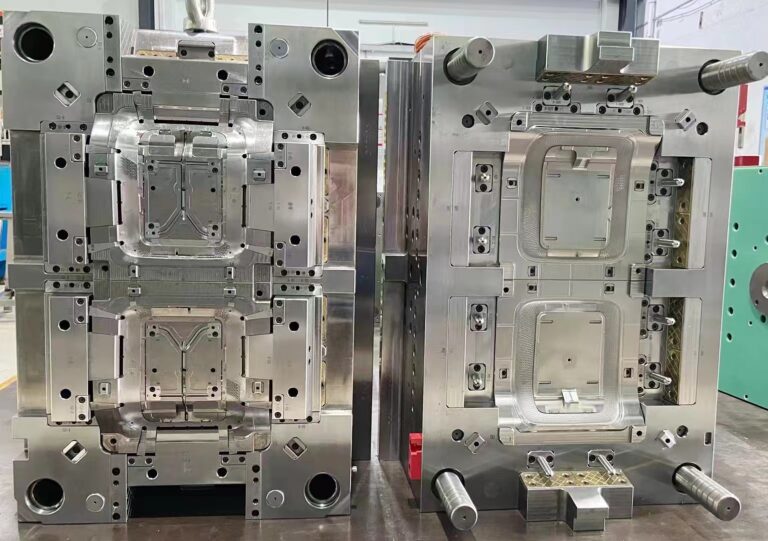

The Injection Mold Explained: Design, Manufacturing, and Fundamentals

In the world of plastic injection molding, the mold—also known as a tool or die—is the core of the entire process. It acts as a precision “negative” of the final part, directly determining the product’s shape, dimensions, and quality. This…

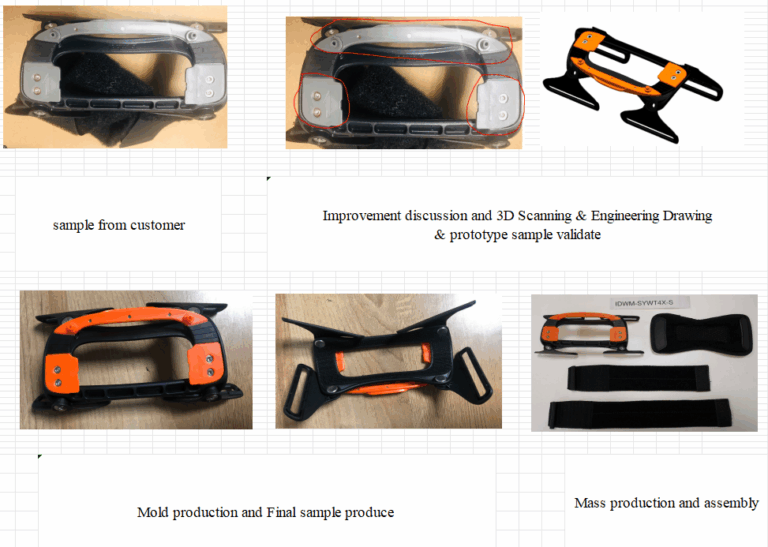

Beyond the Scan: The Unseen Value in a Reverse Engineering Partnership

At Rilong, we handle numerous reverse engineering projects. The initial request from a client is often straightforward: “Here is a sample. Can you make a copy?” While advanced 3D scanning allows us to replicate a product’s geometry with stunning accuracy,…

What is Cycle Time in Injection Molding? The Key to Unlocking Production Capacity

If you work in manufacturing, you’ve heard the term “Cycle Time.” But what does it really mean, and why is it the most critical metric for efficiency and profitability in injection molding? At its core, Cycle Time is the total time required to…